Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrolysis Advice

- Thread starter Vae Victus

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?sarca

I upped my wrenchin skills, now up yours!

Man , those results are undeniable...looks like ill be using this method for all my small parts!

TCSTARK

Master Debater & Cunning Linguist

Another VV thread I am subscribing to! Great write up!

Vae Victus

Posting more than I know

- Thread starter

- #24

Another VV thread I am subscribing to! Great write up!

Thanks Chris - but I took it all from Coolerman's site: http://www.globalsoftware-inc.com/coolerman/fj40/rustremoval.htm

He has done a TON of work.

(Coolerman, rebuild a tyranny already will you?)

Looks like you have nailed the electrolysis technique. As early as you are in your project you could easily step up to a larger tank (rubbermaid totes work well). I agree that you should lose the plastic short protectors. I never found shorting to be a problem. I also got lazy and would often remove the parts , rinse them and use a hand brush to reveal fairly clean metal and shoot them with WD-40. That preserved them until I was ready to break out the grinder with a wire brush to prep them for primer. I would degrease them, wire brush them, degrease them again and etch prime.

Vae Victus

Posting more than I know

- Thread starter

- #26

Looks like you have nailed the electrolysis technique. As early as you are in your project you could easily step up to a larger tank (rubbermaid totes work well). I agree that you should lose the plastic short protectors. I never found shorting to be a problem. I also got lazy and would often remove the parts , rinse them and use a hand brush to reveal fairly clean metal and shoot them with WD-40. That preserved them until I was ready to break out the grinder with a wire brush to prep them for primer. I would degrease them, wire brush them, degrease them again and etch prime.

Thanks Craig. I already am using one tote as my redneck parts washer. Heck, I could even stack them! I'm sure that an electrolysis process producing hydrogen gas, and a container of diesel fuel sitting on top of each other would be OSHA-approved safe.

On the shorting - if the two electrodes (+ & -) touched, you'd get a short, no? Underwater welding would ensue would it not?

Vae Victus

Posting more than I know

- Thread starter

- #27

Nice work!

The current depends on the size of the piece. Looks like 200mA per square inch is optimal:

De Rust discussion

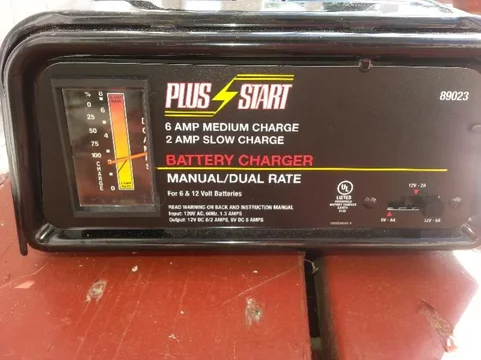

I just hooked up a battery to my bucket, with a battery minder to float charge it. I couldn't get it to run more than 6A on my big front end pieces: brake drum/backing plate, etc...

Just got to keep monitoring it and brushing it down then pull it when clean enough. I was pretty happy with the process. Some pieces it's hard to get a grinder/brush in there so having it done this way requires a lot less work and mess in the garage....

I read that article - interesting tip: "Too many amps means too much electrolyte. you should be pulling about 7 amps, if I remember right. Start with pure water and add your electrolyte a little at a time until you get up to 6 or 7 amps."

Recommend against use of SS wire in the water, only use mild steel such as a coat hanger. There are some sources that report Hexavalent chrome is released as a byproduct of SS electrodes in electrolysis cells. I don't know personally if this is true but I go to the side of caution on this one.

I know wire wheeling after electrolysis makes them look great, but you're burnishing the surface which is harder for paint to adhere to. The surface that comes out the tank, followed by the zinc phosphate acid treatment such as Metal Ready is an ideal paint surface. In fact I'm convinced wire wheeling is the worst way to clean rust off metal. Under an electron microscope, surface rust is going to look like Manhattan made out of jagged metal. Wire wheel flattens that out by folding it all over leaving tiny pockets of air and rust that are not visible to the naked eye. Looks great, just waiting to start rusting under your paint. POR advises against wire wheeling for any of their rust products.

Vae Victus

Posting more than I know

- Thread starter

- #30

I know wire wheeling after electrolysis makes them look great, but you're burnishing the surface which is harder for paint to adhere to. The surface that comes out the tank, followed by the zinc phosphate acid treatment such as Metal Ready is an ideal paint surface. In fact I'm convinced wire wheeling is the worst way to clean rust off metal. Under an electron microscope, surface rust is going to look like Manhattan made out of jagged metal. Wire wheel flattens that out by folding it all over leaving tiny pockets of air and rust that are not visible to the naked eye. Looks great, just waiting to start rusting under your paint. POR advises against wire wheeling for any of their rust products.

Great information and makes sense! Thank you.

Vae Victus

Posting more than I know

- Thread starter

- #31

Recommend against use of SS wire in the water, only use mild steel such as a coat hanger. There are some sources that report Hexavalent chrome is released as a byproduct of SS electrodes in electrolysis cells. I don't know personally if this is true but I go to the side of caution on this one.

If the only stainless is the cathode (negative) which is not consumed, I wonder if it still makes the hexavalent chromium. There is a tiny sliver exposed of the SS wire, where it connects to the alligator clip.

Last edited:

I think you guys are confusing anodes and cathodes here. The anode is the material connected to the postive terminal of the battery charger and the cathode is connected to the negative terminal. The anode will be sacrificed due to losing electrons into the electrolyte. That is why you see pitting on the anodes.

Also, I would not recommend this process on any bolts hardened more than a class 10.9 as hydrogen embrittlement may occur. That is why headbolts are not zinc plated like other bolts.

IMO, this is a great process for removing chrome, but I much prefer sandblasting to strip steel or iron parts of rust and paint.

Also, I would not recommend this process on any bolts hardened more than a class 10.9 as hydrogen embrittlement may occur. That is why headbolts are not zinc plated like other bolts.

IMO, this is a great process for removing chrome, but I much prefer sandblasting to strip steel or iron parts of rust and paint.

Vae Victus

Posting more than I know

- Thread starter

- #33

I think you guys are confusing anodes and cathodes here. The anode is the material connected to the postive terminal of the battery charger and the cathode is connected to the negative terminal. The anode will be sacrificed due to losing electrons into the electrolyte. That is why you see pitting on the anodes.

Also, I would not recommend this process on any bolts hardened more than a class 10.9 as hydrogen embrittlement may occur. That is why headbolts are not zinc plated like other bolts.

IMO, this is a great process for removing chrome, but I much prefer sandblasting to strip steel or iron parts of rust and paint.

Corrected my reversal of terms above. Thanks for catching that.

I read up on embrittlement. Good point on the load bearing parts. I wire wheel bolts - too easy to clean vs electrolysis. It's the convoluted parts that electr. seems to be better at for me. I don't have blasting equipment at the moment.

sarca

I upped my wrenchin skills, now up yours!

Thanks again for this and Coolermans page... I just dipped my first part,..and Ive got bubbles!

Vae Victus

Posting more than I know

- Thread starter

- #36

You all need to talk to 2thdoc--he built an electrolysis unit that works like a charm--cleans anything!

That scumbag hasn't been around much that I've seen. I'll ping him and get him to post pictures. Thanks for the heads up.

Vae Victus

Posting more than I know

- Thread starter

- #37

Thanks again for this and Coolermans page... I just dipped my first part,..and Ive got bubbles!

Pictures and details!

sarca

I upped my wrenchin skills, now up yours!

Vae Victus

Posting more than I know

- Thread starter

- #39

I used baking soda and pulled the test part after one hour. I was amazed. It wiped right off.

Very good. Love to see more pics on your bucket - how you set it up. My wiring was suspect.

TCSTARK

Master Debater & Cunning Linguist

X2 Sarca... Show us detailed pics of the setup

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)

VVVV Awesomeness. VVVV

VVVV Awesomeness. VVVV