Dang good looking 60 you have there. How do you like the snorkel that you have on there? Where did you get the sliders? Once again, very nice. Can't wait to get mine all together and running.

Bluehawk,

Thanks man, I love the snorkel, my issue is the airbox. It's a bit smaller than what I would prefer. Just be ready to keep cleaning bugs from your filter, unless you turn it around like i did for the winter. I got the sliders from

http://www.cruisinoffroad.com/ the guy is great, very professional and timely. the sliders were the first ones he made for a 60/62 frame. I'm debating whether or not to get my rear bumper made by him, but that will be later down the line as funds become available. I look forward to watching your build.

BTW Big Red is a 62, not that I'm a stickler for these kinds of things.

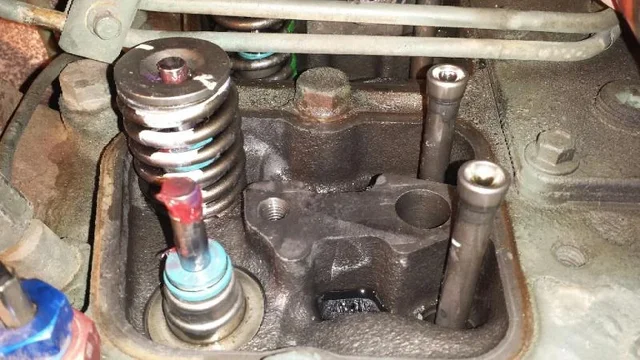

There may be still plenty of pressure to get oil up to the top end and through the turbo, but as you start to turn things up on this old mill, I would not want to restrict flow in any way. Bearings do love oil!

Adding fittings to your filter housing may not change a thing on the gauge either, the restriction may be in the remote filter assembly it self.

But it would relieve the stress on the lines and prevent a kink in the line later on.

YMMV

The truck you have built looks awesome! Just go easy till your sure

Pacer,

Thanks for your input, info like this is how I learn and is always welcomed. The oil pumps into the filter right away, you can feel it in the lines, it just takes a second for the gauge to register. I'm wondering if I need to add a bit more oil for there to be no lag. I went to look for fittings today and didn't find any at the local auto store. I swung by tractor supply and the ones I need ( two male ends with a 90* angle ) were out of stock. I'll try to swing by that store Davegonz linked me to sometime next week.

I'm very careful with this rig because the cost of building it and the time I waited for it to be drivable still pains me. I don't race it, and I don't get caught up in the foolhardiness that some guys get caught in when wheeling. I've broken lots of rigs being stupid but those were paid for by uncle sam

. This one is my baby and my son already claimed it as his when I die. He's 5 and he can't wait.

I'm installing new springs next and a few accessories, then I'm just going to take it easy and hopefully do some camping.

If I don't see anyone online tomorrow, y'all have a happy thanksgiving with your families and loved ones, this will be the first one I spend with my son and I'm excited.