- Thread starter

- #421

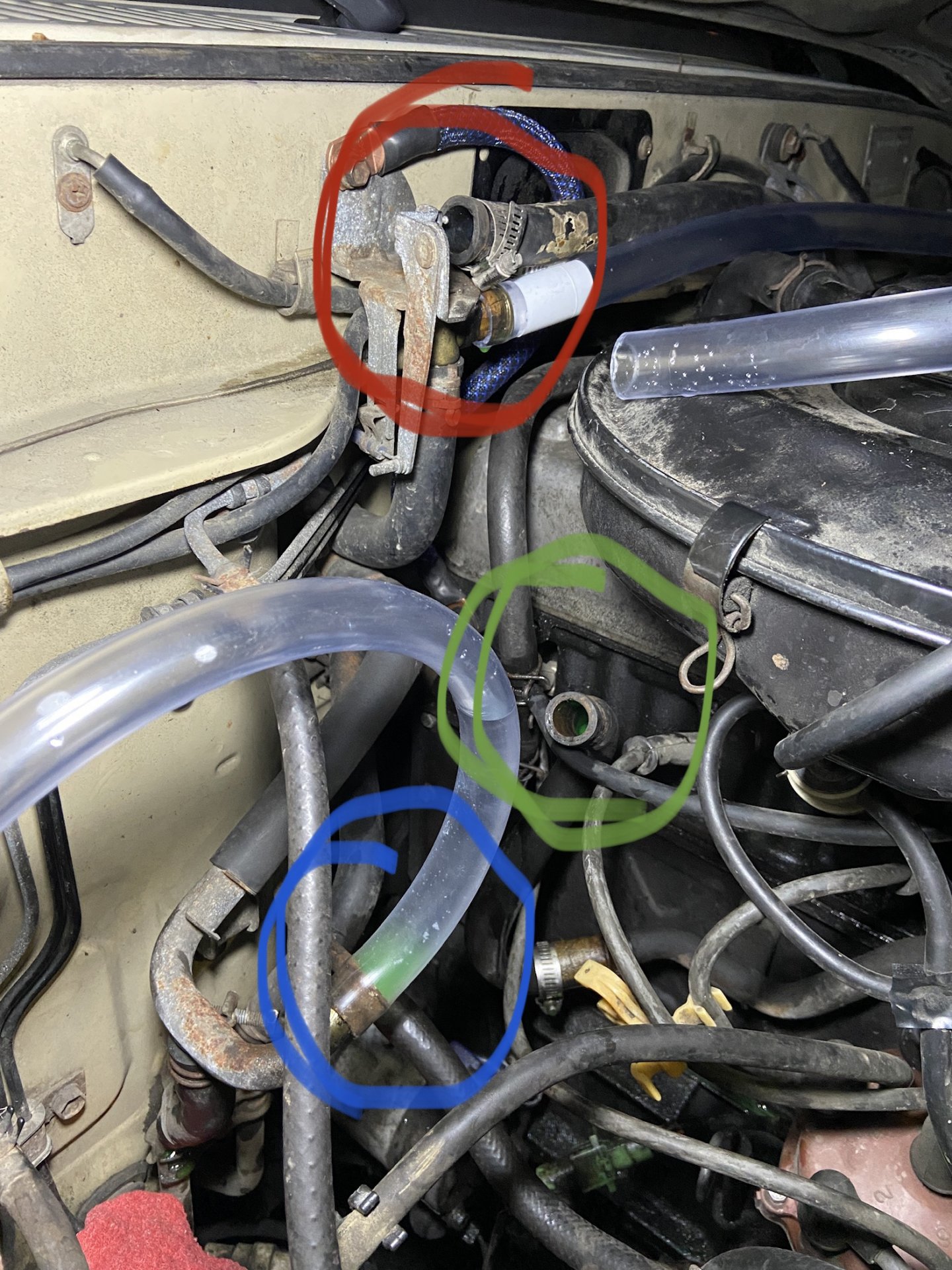

The heater core flush went alright. My hoses are old and tough so finding a combination that I could remove to do the flush was difficult. I ended up back flushing with hose water and was rewarded with cloudy green, cloudy brown, and finally clean water from the core. My final solution was to connect the hose to the heater out line (blue), plug the out line (green), and run a tube to a bucket from the heater in line (red). I also plugged the engine side of the red connection. This way I didn’t risk getting any crud from the core in my engine or the rear heater but I do now have some hose water mixed into the coolant. I also made a mess on the street by doing this without draining my coolant first.

Still... I now have heat! I haven’t measured it so I can’t say how it compares to other cruisers but it’s a clear and noticeable improvement for me.

Still... I now have heat! I haven’t measured it so I can’t say how it compares to other cruisers but it’s a clear and noticeable improvement for me.