Nice and clean! spark plug cover looks really out of place though with how nice the valve cover looks.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds The Trail Snail Build | Above Average Overlandish

- Thread starter SmokingRocks

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #422

Thanks! Yup I agree, unfortunately they started out the day black... Half way through the degreasing I noticed the paint was not having it. So I've got a project for another day

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #423

Tried to design my APRS PTT audio sensing trigger relay tonight.... Didn't have all the right components, so I spent several hours trying to design a back door method. Didn't get to far, my old time delay relay was ground triggered which made it simple using a transistor but this new time delay relay needs 5-12v to trigger it..

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #424

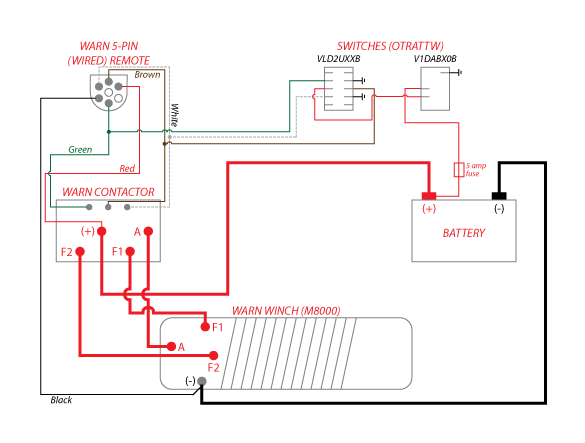

wired in cab winch controls tonight. I need to get a SPST switch with a safety latch to prevent accidental switching and the on-off-on switch needs to be traded out for a momentary unit.

This is the wiring diagram used for the warn zeon winches

This is the wiring diagram used for the warn zeon winches

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #425

Front axle service time! Going to chase out the crunchy pop sound I get when turning, I'm theorizing that it may be the trunion bearings, hoping its not the birfields.

ppc

M Go Blue

I don't understand why if you think the knuckle bearings are the problem why you posted only buying the gaskets and seals. In my opinion anytime you open the knuckle the knuckle bearings should be replaced as they always show some degree of wear. The exception being if you might only have a few thousand miles or less since a previous replacement. Given the amount of effort and costs in opening/resealing the knuckle the bearings are relatively cheap in comparison so eliminate the risk.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #427

So the seal kit is the base, my thought was to open it up and see whats going on. The hub bearings are sub 15,000 miles and I am not experiencing issues which indicate their at fault.

Now the trunion bearings have 50k on them, while they should be ok I'm curious to see their condition. If they need replaced the parts counter already has a set for me, but at $50 per side I'd like to avoid this. Truthfully as much as I don't want to admit it I suspect the birfields are the responsible for the pops and the inner axle seals & worn out wipers are responsible for the molly soup. We'll see when I get in there.

If all the bearings show no signs of abnormal wear and the birf's look good its just getting seals, and I'll get to use my new Wits in axle seal over driver for the first time.

PS. another reason you don't see bearings on the list is because I keep 8 inner & 8 outer bearing sets on hand at all times. A full set lives in the rig and a full set is in parts storage.

Now the trunion bearings have 50k on them, while they should be ok I'm curious to see their condition. If they need replaced the parts counter already has a set for me, but at $50 per side I'd like to avoid this. Truthfully as much as I don't want to admit it I suspect the birfields are the responsible for the pops and the inner axle seals & worn out wipers are responsible for the molly soup. We'll see when I get in there.

If all the bearings show no signs of abnormal wear and the birf's look good its just getting seals, and I'll get to use my new Wits in axle seal over driver for the first time.

PS. another reason you don't see bearings on the list is because I keep 8 inner & 8 outer bearing sets on hand at all times. A full set lives in the rig and a full set is in parts storage.

ppc

M Go Blue

I was referring to knuckle/trunnion bearings should always be replaced, not wheel bearings. Both Marlin and Cruiser Outfitters sell seal kits including the trunnion bearings for $119 and $115 per axle, ~$30 per side not $50. At 50k miles your are going to find at minimum wear marks in the trunnion races.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #429

Should've read more closely huh?

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #430

Saw a 94 at the pull&pay in denver. Unfortunatley it was more picked over than I thought.

That said I got:

Trunions on the driver side were nackered. Looks like the birf contacted it quite a bit.

I looked inside the ball and saw more evidence of this

Not sure how that could have happened... bad wheel bearings? Worn out trunions?

I did get to use my new wits end product. Thanks @NLXTACY

That said I got:

- sunroof glass (need a better gasket)

- sunroof rails (mine were slightly broken)

- Driver side mirror (my housing is broken)

- Sun Visor

- Many dash pieces

- Fuel Pump relay

- EFI fuse

- hub stuff

- May go back for the birfield and rear axle shafts.

Trunions on the driver side were nackered. Looks like the birf contacted it quite a bit.

I looked inside the ball and saw more evidence of this

Not sure how that could have happened... bad wheel bearings? Worn out trunions?

I did get to use my new wits end product. Thanks @NLXTACY

That is a curious problem there... Bad wheel bearings shouldn't be the cause of that issue. What did the bushing inside the spindle look like? Were the trunion bearing cap/steering arm bolts tight? Is there a chance your axle housing is bent?

I'm going to guess incorrect trunion shims.

Outsane

Supporting Vendor

Just read through the build, inspiring.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #434

NEW TIRES!!!! Theres soooooooooo much RUBBER!!!! AHHHH!!!

But seriously, I got a new set of Toyo Open Country MT's 315/75 R16. Why did I get the same tires?

Also cut my Man-a-fre UCA's free... The metal sleeve in the polly bushing became one with the bolt. Now I need new bolts, new heims and I'd like to ditch the poly and press in a bushing.

But seriously, I got a new set of Toyo Open Country MT's 315/75 R16. Why did I get the same tires?

- Last set made it 4 yrs and 60,000+ miles

- Had them down to 6-8psi for snow wheeling and never blew a beed

- never had a puncture or sidewall slash

Also cut my Man-a-fre UCA's free... The metal sleeve in the polly bushing became one with the bolt. Now I need new bolts, new heims and I'd like to ditch the poly and press in a bushing.

nukegoat

Should have bought a Jeep

WhyPS. another reason you don't see bearings on the list is because I keep 8 inner & 8 outer bearing sets on hand at all times. A full set lives in the rig and a full set is in parts storage.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #436

why not

I like to be stocked. I always try to have two full changes for all the bearings on hand, but typically I only have 2 inner and 2 outer new bearings on hand and then 2 inner / 2 outer used bearings as back ups.

The new ones live in the rig alone with a complete knuckle seal kit. Yes I have had to do bearing/hub work on the trail.

Last edited:

I'm sure you've never had to replace all four bearing sets on the trail but you do you.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #438

I'm sure you've never had to replace all four bearing sets on the trail but you do you.

No I haven't had to do all 4 bearing sets. I have had to do 1 set so I was glad I had the bearings on hand. Whats wrong with travling with enough bearings to service two hubs? If someone else on the trail has their hub fall off (yep seen this too) they would be very happy to have someone there with parts.

Many of us extended wheelers carry trails spares, in addition to the bearings I carry:

- one rear LCA (used it before)

- Rear Driveshaft (used it before)

- Birf

- brake lines & bender (used it before)

- hoses, clamps and hose tape

- fan belts

- FPR, CO relay, EFI fuse & misc electrical components (used it before)

- engine & diff oil, trans fluid, brake fluid, distilled water, grease gun

- On trail welding kit (used it before)

Not sure how much trail damage you've experienced, and maybe you are one of those guys who just puts a tourniquet on and limps home. I'm not, if I'm out for a week+ I want to be able to continue to have fun if I break something on day 1. I've seen enough from others and several of my breaks to happily surrender a small amount of space for piece of mind.

Ya ya I hear the guys out there saying "don't abuse your equipment and it won't fail". Tell that to my buddy bob who had his coil over snap on a fire road due to a manufacturing issue, it took out the brake line. I'm easy on my snail but I'm not coddling her, I bought her for a reason.

SmokingRocks

hopelessly addicted to Cruisers

- Thread starter

- #439

Measured the control arm so I can order replacements, I need:

Also do I need to remove the heim to figure out the thread pitch and type? I don't have a pitch gauge but I can get all the dimensions.

- New Heims

- New Poly Bushings (would prefer pressing in OEM bushings if I could)

- Unfortunately the M02854 number doesn't return anything in a google search

Also do I need to remove the heim to figure out the thread pitch and type? I don't have a pitch gauge but I can get all the dimensions.

Measured the control arm so I can order replacements, I need:

Can anyone point me in the direction of a good online vendor?

- New Heims

- New Poly Bushings (would prefer pressing in OEM bushings if I could)

- Unfortunately the M02854 number doesn't return anything in a google search

Also do I need to remove the heim to figure out the thread pitch and type? I don't have a pitch gauge but I can get all the dimensions.

View attachment 1783011 View attachment 1783012

It may or may not help you, but make sure it's a zero after the M in that bushing part number - not the letter O. I have no idea if Metal Tech uses OEM sized sleeves, but a quick measurement will tell you if you can just press in OEM bushings. A pressed-in rubber bushing would certainly be my choice over poly.

On the heim, just measure the diameter of the threads, and count how many threads are in 1" of the shank. Then you need to measure the diameter of the hole in the joint. No reason you need to remove the joint yet. Heims are sold by hole diameter, and shank diameter and threads per inch (TPI). Most larger shank diameters are only available in 1 thread pitch anyways, so there won't be too many options. Easy peasy.

Similar threads

- Replies

- 9

- Views

- 1K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)