I have these two rear accumulators that passed the pencil test if anyone wants them. (I replaced all 4 accumulators when my fronts failed.) I don’t know how much longer these will be good but the price is right! $20 for both, plus shipping. Please PM me if you’re interested so we don’t clog this thread up. (Admins, maybe this should go in classifieds instead?)

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The ABCs of AHC - How to Measure, Flush, and Adjust all in one place (2 Viewers)

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Guys, I really need some help with AHC, stuck at cross-level/sensor height adjustment step.

As part of baseline, I flushed the AHC, and I get 10+ marks on the reservoir test.

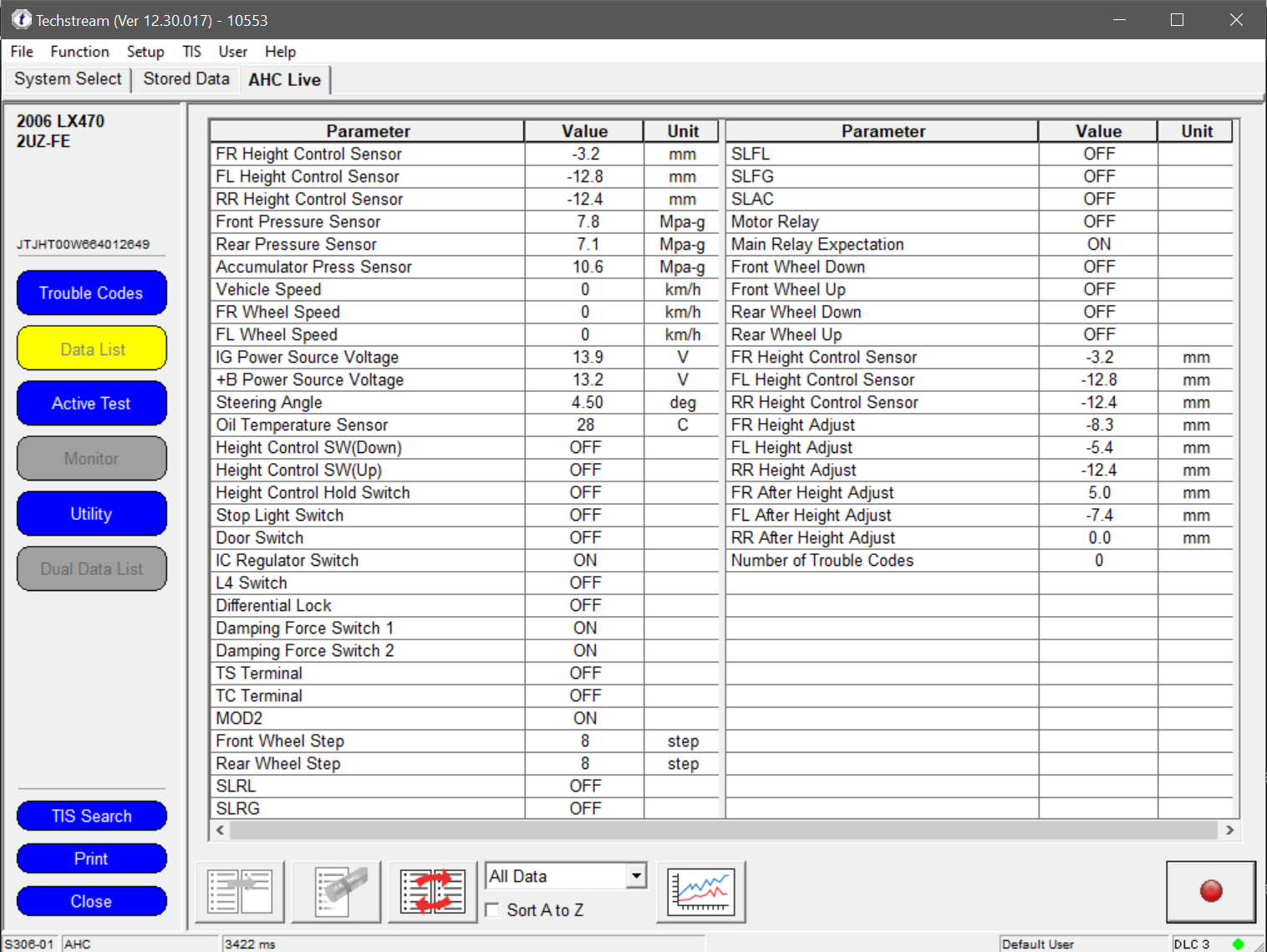

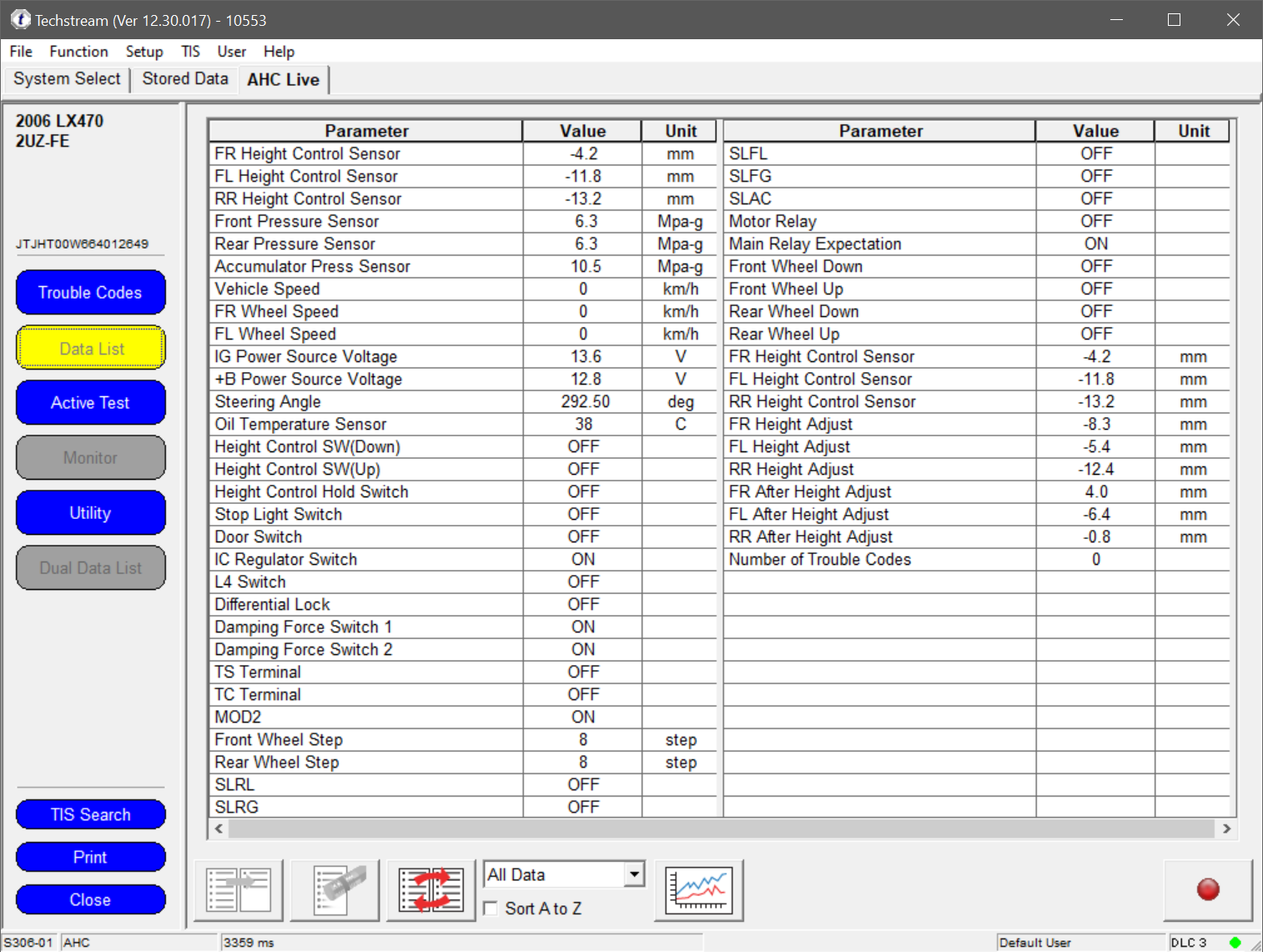

These were my first readings after flush:

Then I attempted to cross-level, and after a hell of a time trying to find someplace level to measure, I was getting:

19.5 front, 20.75 rear

What's weird is that at some point in the [torsion bar -> drive -> measure] cycle, I cranked both torsion bars clockwise and ended up with 19" on the fronts. I really don't understand how that happened. My sensors were not loose. Anyway, after that I cranked up the torsion bars some more, and ended up with:

19.5 front, 20 rear

I don't understand how both front and rear dropped so much when I was cranking up.

At this point I was worried about running out of travel on the torsion bar adjustment (I have no idea if that's a possibility). After crossleveling, these were the readings:

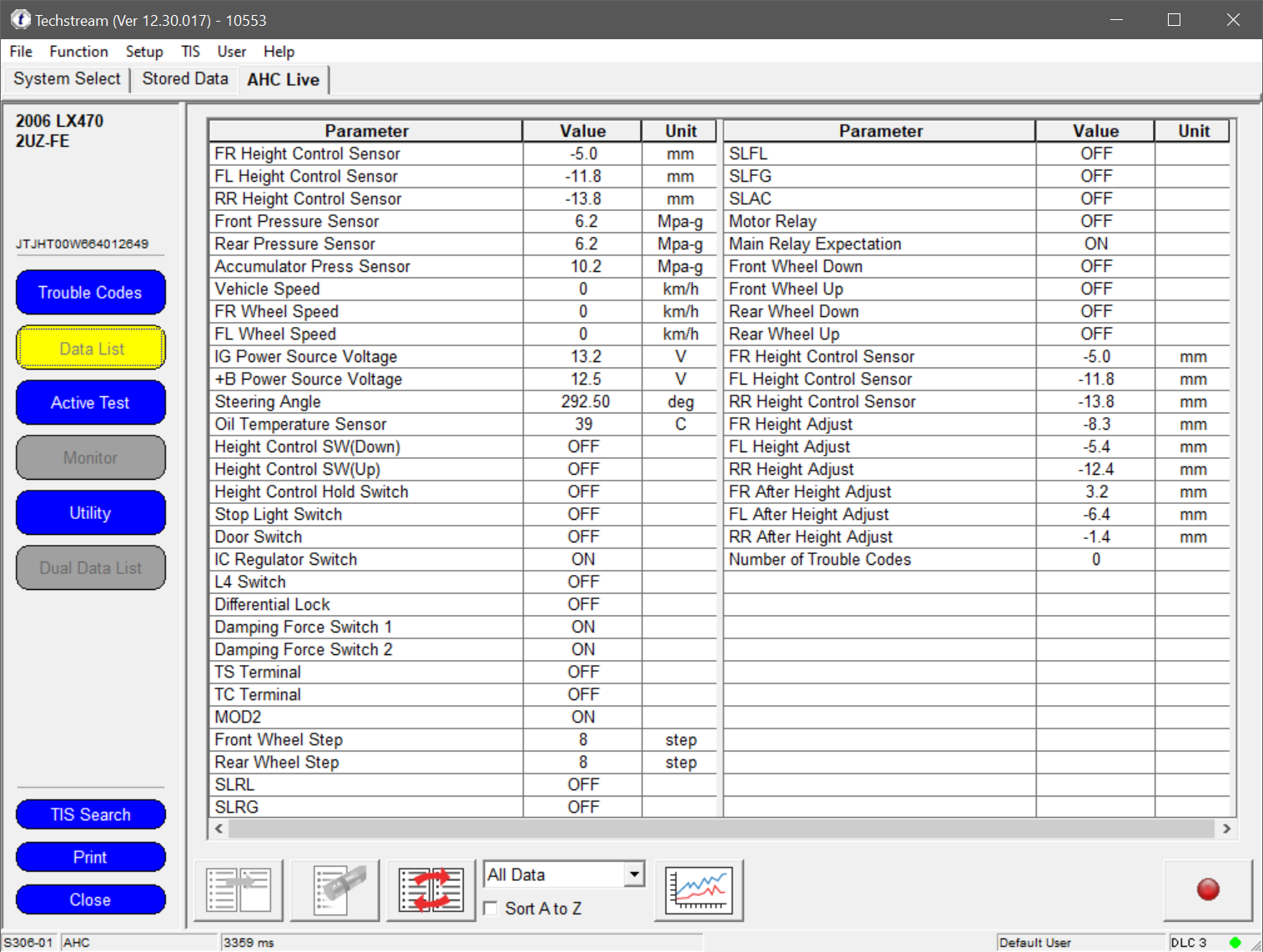

So I moved on to adjusting sensor heights. I got all three sensors to these readings:

As part of baseline, I flushed the AHC, and I get 10+ marks on the reservoir test.

These were my first readings after flush:

Then I attempted to cross-level, and after a hell of a time trying to find someplace level to measure, I was getting:

19.5 front, 20.75 rear

What's weird is that at some point in the [torsion bar -> drive -> measure] cycle, I cranked both torsion bars clockwise and ended up with 19" on the fronts. I really don't understand how that happened. My sensors were not loose. Anyway, after that I cranked up the torsion bars some more, and ended up with:

19.5 front, 20 rear

I don't understand how both front and rear dropped so much when I was cranking up.

At this point I was worried about running out of travel on the torsion bar adjustment (I have no idea if that's a possibility). After crossleveling, these were the readings:

So I moved on to adjusting sensor heights. I got all three sensors to these readings:

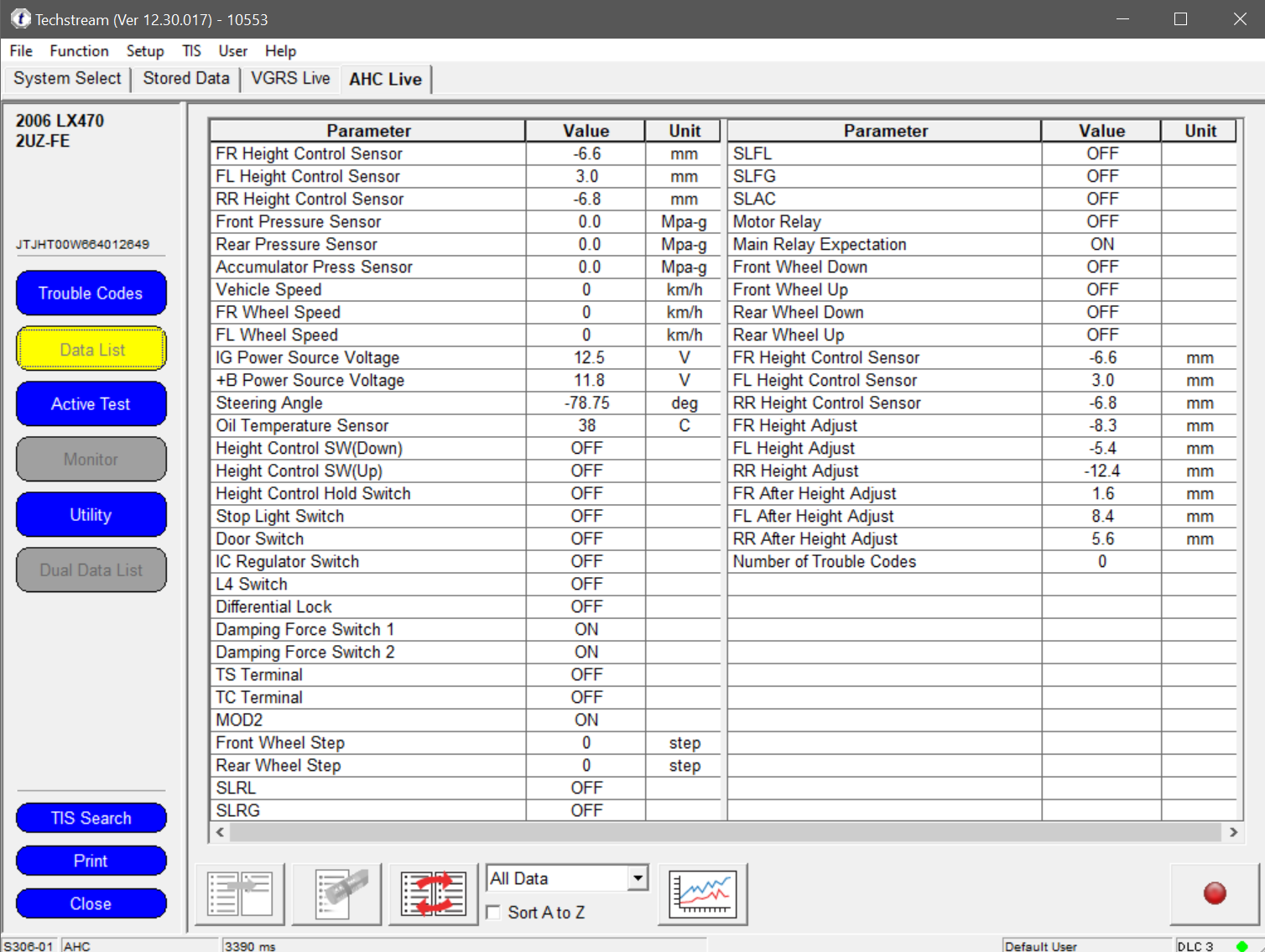

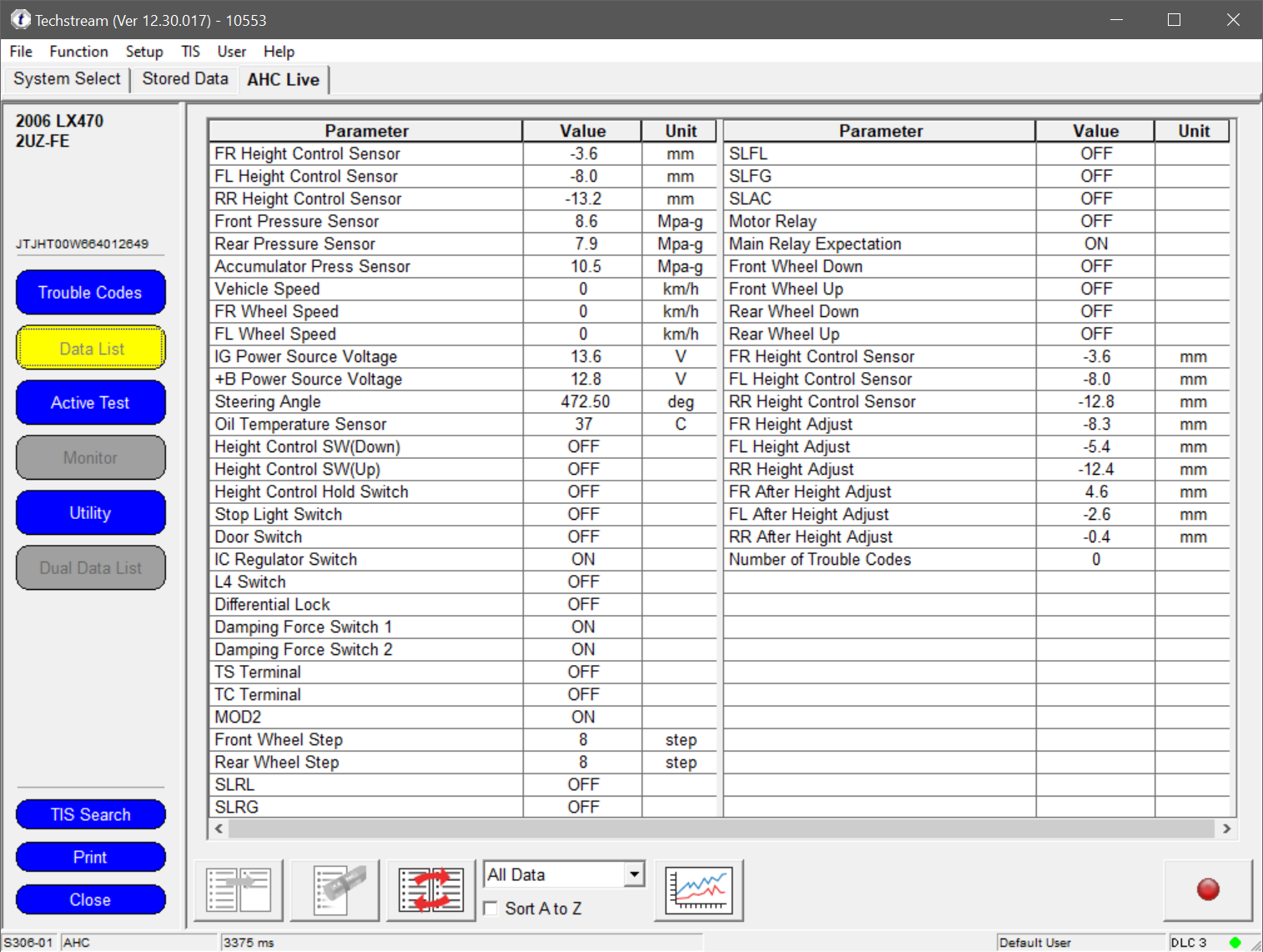

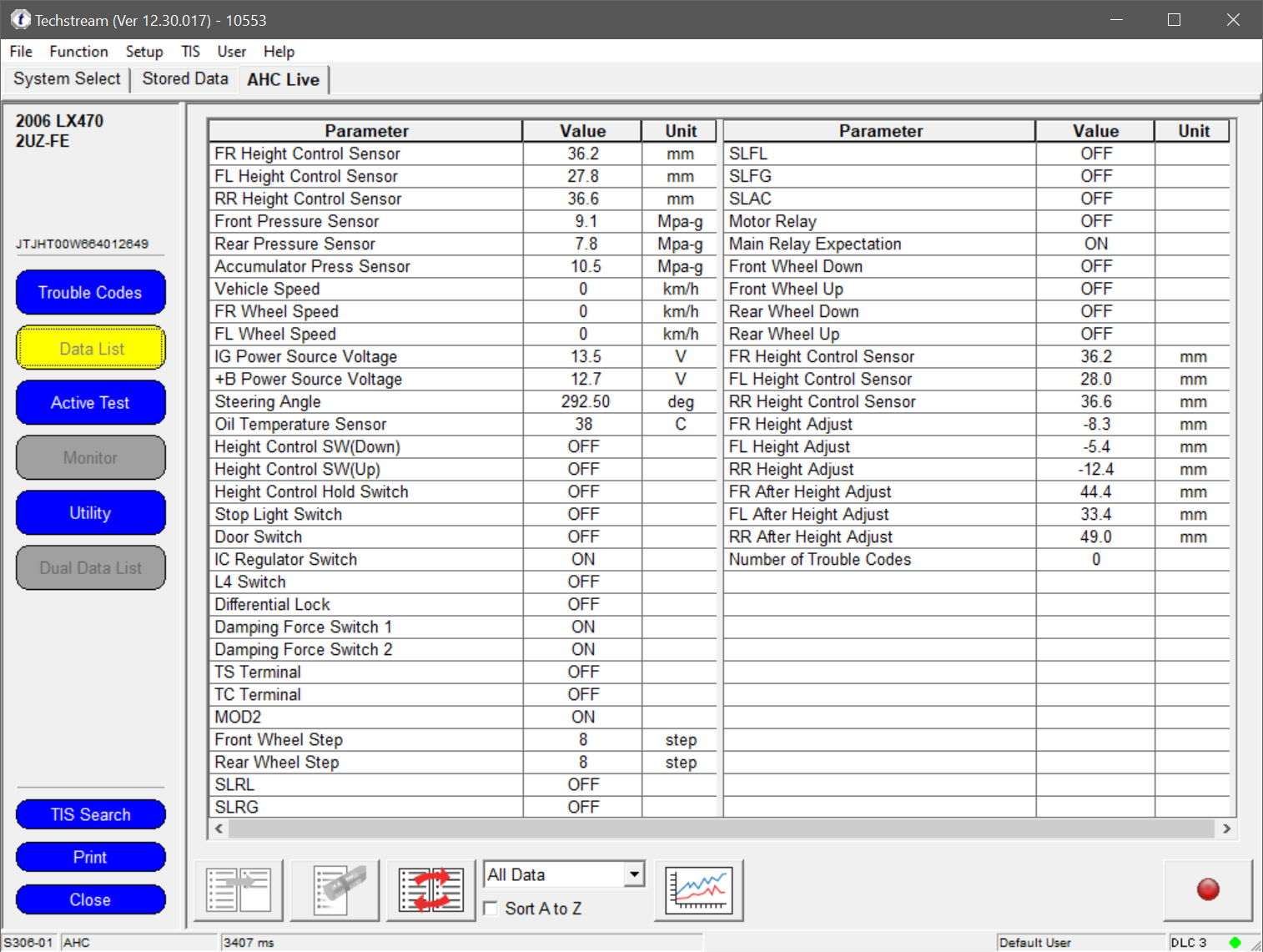

Then I did a N-> H -> N -> L -> N cycle and these are the readings:

N

H

N

L

N

Any ideas?

I was wondering if the steering angle was causing some kind of problem, so I tried to adjust VGRS, and when that didn't work, I figured, hey, maybe the wheel needs to be 'unwound' and so I rotated it a bunch one way. Then I heard bad scraping/clackety noises from the wheel, the airbag light came on, and that's when I learned what a clockspring mechanism is...

Anyway, an aftermarket clockspring is on order, but in the meantime, what the heck do I do? Go up on the torsion some more? Is there danger of running out of T bar adjustment? Is the steering angle even a factor?

N

H

N

L

N

Any ideas?

I was wondering if the steering angle was causing some kind of problem, so I tried to adjust VGRS, and when that didn't work, I figured, hey, maybe the wheel needs to be 'unwound' and so I rotated it a bunch one way. Then I heard bad scraping/clackety noises from the wheel, the airbag light came on, and that's when I learned what a clockspring mechanism is...

Anyway, an aftermarket clockspring is on order, but in the meantime, what the heck do I do? Go up on the torsion some more? Is there danger of running out of T bar adjustment? Is the steering angle even a factor?

To clarify,

1. Crosslevel fronts with AHC OFF

2. Turn AHC back ON

3. If front height not in spec, adjust using the sensor adjustment? I don't get this part - am I trying to get the "height control sensor" readings to 0 in Techstream, OR am I trying to adjust the front heights by re-measuring hub-to-fender heights? And how would I know which way to move the sensor heights to adjust the hub-to-fender height?

Never mind, clearly I need to keep reading!

Last edited:

Ah crap, it doesn't say in the first post, and I failed to read the additional posts by @IndroCruise , that the crossleveling needs to be done with the AHC off. Wonder if that's why weird height changes happened in the middle of my cross-leveling experiment.

To clarify,

1. Crosslevel fronts with AHC OFF

2. Turn AHC back ON

3. If front height not in spec, adjust using the sensor adjustment? I don't get this part - am I trying to get the "height control sensor" readings to 0 in Techstream, OR am I trying to adjust the front heights by re-measuring hub-to-fender heights? And how would I know which way to move the sensor heights to adjust the hub-to-fender height?

Never mind, clearly I need to keep reading!

You are probably across it all by now -- but the following notes were prepared and may as well be posted now for more happy reading .....

Keep calm and carry on!! A few things have been mixed up in the descriptions in your Post #362 and your Post #363 but no damage is done. You are just having a version of the same ‘learning experiences’ that we all had in the beginning ….

Start the engine, set the height to “N” -- and let the vehicle height stop where it will.

Now, turn “OFF” the engine and ignition (which then turns “OFF” the AHC system) and leave them all “OFF” until mentioned later -- because it is safer this way, and, because the FSM says so.

Forget about Techstream and lock it away until Step 13 below,

Forget about the ‘reservoir test’ -- do not even think about this until Step 23 below -- otherwise it is not comparable with the FSM numbers and tells you nothing useful.

You have done very well so far -- suggest continue with patience and determination. Here are some notes which may help:

The underlying sequence in these notes for adjusting the AHC system is no different to other Posts you may have read -- the sequence is always the same when making AHC adjustments and measurements -- these notes just add more detail which may clarify some points:

1. ‘Cross-level’ the Front of the vehicle on a level surface using only the torsion bar adjusters and a tape-measure (never the Height Control Sensor adjusters and Techstream). The first attachment (extract from FSM) gives some guidance – might need to wind up one side and wind down the other. Per FSM, IT DOES NOT MATTER what the tape-measurements are at this stage -- you just want them to be equal within +/- 10 millimetres per FSM, and preferably even closer to equal,

2. You do not want the Active Height Control (AHC) system to be ‘active’ at this ‘ cross levelling’ stage -- otherwise the AHC system may attempt to make ‘corrections’ and in effect try to contradict your ‘adjustments’ while you are making them! If this happens, confusion, frustration and re-work are absolutely guaranteed!!

3. One consequence is that if the Height Control Sensors are so maladjusted (or faulty) that they send wrong or widely different signals to the ECU, then the ECU may enforce the ‘fail safe function’ in which AHC operation and TEMS operation are both prohibited – see second and third attachment. This is easily fixed -- but it requires that all previous adjustments be unpicked,

4. The purpose of Front ‘cross levelling’ step is two-fold – (i) to eliminate any unacceptable side-to-side ‘lean’ -- within +/- 10 millimetres (+/- 0.4 inches) side-to-side on the vehicle when on a level surface, not carrying any poorly distributed loads or fittings, wheels straight ahead, and, (ii) to equalise the load on the LHS torsion bar and the RHS torsion bar,

5. On an AHC-equipped vehicle, ‘cross-levelling’, and, the torsion bar adjusters have nothing to do with setting the ‘ride height’ of the vehicle,

6. On an AHC-equipped vehicle, the Height Control Sensors do not and cannot be used to adjust the relative side-to-side heights of the vehicle and so the Height Control Sensors adjusters cannot be used in ‘cross levelling’. This is because in the AHC system, LH Front and RH Front are hydraulically connected – via the Front Gate Valve in the Control Valve Assembly which is “normally open” at all times except when the vehicle is cornering at speed. Ditto the AHC system at LH Rear and RH Rear and via the Rear Gate Valve. So any effort on just one side at the Front with the the Height Control Sensors adjusters will simply raise or lower the vehicle when it is started -- and it will result in wrongly adjusted Sensors, ongoing confusion and possibly the 'fail safe function' being implemented by the Suspension Electronic Control Unit (ECU),

7. For now, assume that the vehicle is not in ‘fail safe function’ -- this can be confirmed if the AHC system is able to raise and lower the vehicle,

8. With ‘cross levelling’ sorted, it is time to set the ‘ride height’ of the vehicle at “N” height -- for a stock vehicle (not lifted), irrespective of tyre and wheel size, targeting Front hub-to-fender 19.75 inches (or 500 millimetres) and Rear Front hub-to-fender 20.50 inches (or 520 millimetres), measured with a tape-measure. Note that these are not Toyota nor Lexus FSM measurements but are easy-to-measure, widely accepted approximations which have stood the test of time.

9. Different ‘ride heights’ can be targetted, for example if the aim is a so-called ‘sensor lift’ -- but suggest leave that until later. First, adjust the vehicle in standard condition at “N” height,

10. The point is that these ‘ride heights’, when set, are the heights to which the AHC system will self-level the vehicle every time at “N” height setting, provided that the 16 to 24 years old Height Control Sensors actually are in healthy condition (???), and, the AHC system is functioning correctly,

11. Again, assume that the vehicle is not in ‘fail safe function’ -- this can be confirmed if the AHC system is able to raise and lower the vehicle,

12. Again, also assume that the Height Control Sensors are in healthy condition -- noting that the absence of a Height Control Sensor Diagnostic Trouble Code (DTC) does not provide assurance that these Sensors are healthy -- removal and testing with a multimeter per FSM is necessary. (Note: If original, the Height Control Sensors on a 2006 LX470 are now 17 years old -- they are long-life items but live in a hostile environment, they have moved with each and every up-and-down vertical movement of the suspension as the vehicle travels -- they are subject to wear, weakening of internal contacts, water ingress, internal corrosion, harness problems – they do not last forever. At this age, suggest always remain suspicious of the condition of the Height Control Sensors -- especially when large differences are seen between the Height Sensor readings on Techstream when the vehicle is known to have been ‘cross-levelled’ correctly with equalised side-to-side heights per Step 1, and is sitting on a level surface),

13. Now break out Techstream -- initially to use with Ignition “ON” but with engine “OFF” (because initially some static readings are necessary without the AHC system itself attempting any auto adjustments),

14. ALWAYS, WHEN MAKING ADJUSMENTS ON THE AHC SYSTEM, ENSURE BEFORE STARTING THAT VEHICLE STANDS ARE PLACED UNDER THE CHASSIS RAILS FOR PERSONAL SAFETY, IN A WAY THAT ENSURES THAT IT IS IMPOSSIBLE FOR THE VEHICLE BODY TO DESCEND ONTO A HUMAN BODY UNDER THE VEHICLE IF A MISTAKE IS MADE,

15. There are various ways to set the chosen ‘ride height’. They all involve manual adjustments and tape-measurements and are not done by pressing some button in Techstream. All methods have the same principles in common: (i) to physically adjust (raise or lower) the Front and Rear of the vehicle body relative to the wheel hub until the desired hub-to-fender tape-measured distances are achieved, then (ii) hold that position, then (iii) with the vehicle at the set ‘ride heights’ with Ignition “ON” but with engine “OFF”, the Height Control Sensors readings are adjusted as close as possible to zero (within +/- 0.2 inches or within +/- 5 millimetres) per Techstream,

16. Using the “Height Control Operation Test -- Active Test” with engine “ON” to physically raise or lower the vehicle is one method of adjusting the preferred ‘ride heights’. This described in in Section 5 at Page 6 of the fourth attachment (sourced long ago from the highly experienced @PADDO -- and it works for me). The procedure must be followed exactly. It uses Diagnostic Link Connector 1 (DLC1) in the engine bay above the RHS Front wheel arch – an unbent paper clip or similar suffices in place of Special Service Tool SST 09843-18020 -- or you can buy this jumper lead from a local Dealer or elsewhere. Note: Techstream cannot be connected and operated at DLC3 under the dash during this procedure involving DLC1,

17. With the vehicle in position at the preferred ‘ride heights’ to match “N” height setting, then with Techstream attached and with Ignition “ON” but with engine “OFF”, move the sliders on the Height Control Sensor adjusters until the Height Control Sensor readings are as close as possible to zero (within +/- 0.2 inches or within +/- 5 millimetres) per Techstream readings,

18. It may be necessary to use the double-ended heim bolts on the Front to gain the necessary movement, just be aware that these are very fiddly to adjust,

19. Moving the Height Control Sensor adjusters is awkward because this involves reaching around the tyre -- it easier on a platform hoist, wheels must be supporting the vehicle, not hanging free,

20. An alternative method is to remove each Front wheel one-by-one and then use a jack under the Lower Control Arm to produce the required actual tape-measured Front hub-to-fender distance, then move the Height Control Sensor adjuster as close as possible to zero while observing the Sensor reading on Techstream with Ignition “ON” but with engine “OFF”,

21. The Rear Height Control Sensor adjuster (slider only, no heim bolt) can be reached from under the vehicle -- AGAIN, TAKE CARE AS MENTIONED IN STEP 14,

22. Then when the ‘ride heights’ are set as desired, and not before, check Front and Rear AHC pressures using Techstream -- adjust as necessary with torsion bar adjusters in Front (and/or with torsion bar re-indexing if the Front is very heavy), and, at Rear with spacers to pre-load coil springs or preferably upgrade the coil springs. Before recording AHC pressures, always wait ~30 seconds after the “N” to “LO” to “N” height movement is completed (green AHC light stops flashing in instrument cluster) to be sure that the AHC Pump has completed the raise and also has re-charged the Height Control Accumulator. (Note that use of the torsion bars will not cause changes to ‘ride height’ because ‘ride height’ is controlled by the Height Control Sensor signals to the Suspension ECU),

23. When the ‘ride heights’ are set as desired, and, Front and Rear AHC Pressures are within the FSM-specified range, then and not before, check overall condition of ‘globes’ by observing how much AHC Fluid is displaced by the ‘globes’ to the AHC Tank -- looking for the difference in fluid levels after moving from “HI” height to “LO” height per FSM -- should be around 14 graduations with new ‘globes’ under FSM-specified conditions. (Note: Just to be clear, correct AHC pressures within FSM ranges tells nothing about 'globe' condition),

24. Note that all AHC-related adjustments are made at “N” height setting -- no adjustments are possible at “LO” height nor at “HI” height. However, observations at “LO” and “HI” can be a useful check – but beware of inconsistencies if there are differences in torsion bar settings, rear spring condition, wear and tear in mechanical suspension parts – bushings, control arms, ball joints, bearings etc, etc – or uneven tyre pressures or different tyre wear side-to-side. It is always good to measure times to raise “LO” to “N” and “N” to “HI” -- slow times may be an early indicator of a partial blockage building up in the internal strainers inside the AHC Pump, or, may be an indicator of faults in the Height Control Sensor harness and circuits, causing inconsistent signals to the ECU and resulting in slow response times.

Attachments

-

AHC - Cross level per FSM LoRes.pdf178.8 KB · Views: 98

-

AHC - Adjust Heights and Height Control Sensor per FSM.pdf1.3 MB · Views: 122

-

FSM Diagnostics re AHC Height Control Sensors.pdf2 MB · Views: 105

-

AHC suspension precheck and damper check.pdf406.1 KB · Views: 105

-

AHC HI-LO Test per FSM.pdf105.1 KB · Views: 67

Last edited:

15. There are various ways to set the chosen ‘ride height’. They all involve manual adjustments and tape-measurements and are not done by pressing some button in Techstream. All methods have the same principles in common: (i) to physically adjust (raise or lower) the Front and Rear of the vehicle body relative to the wheel hub until the desired hub-to-fender tape-measured distances are achieved, then (ii) hold that position, then (iii) with the vehicle at the set ‘ride heights’ with Ignition “ON” but with engine “OFF”, the Height Control Sensors readings are adjusted as close as possible to zero (within +/- 0.2 inches or within +/- 5 millimetres) per Techstream,

16. Using the “Height Control Operation Test -- Active Test” with engine “ON” to physically raise or lower the vehicle is one method of adjusting the preferred ‘ride heights’. This described in in Section 5 at Page 6 of the fourth attachment (sourced long ago from the highly experienced @PADDO -- and it works for me). The procedure must be followed exactly. It uses DLC1 in the engine bay above the RHS Front wheel arch – an unbent paper clip or similar suffices in place of Special Service Tool SST 09843-18020 -- or you can buy this jumper lead from a local Dealer or elsewhere. Note: Techstream cannot be connected and operated at DLC3 under the dash during this procedure involving DLC1,

17. With the vehicle in position at the preferred ‘ride heights’ to match “N” height setting, then with Techstream attached and with Ignition “ON” but with engine “OFF”, move the sliders on the Height Control Sensor adjusters until the Height Control Sensor readings are as close as possible to zero (within +/- 0.2 inches or within +/- 5 millimetres) per Techstream readings,

Thank you IndroCruise!

Just for clarification, after cross-leveling:

1. Perform the height control operation test / active test, using the paperclip in DLC1. This would let me set the desired front hub-to-fender height close to 19.75" simply using the AHC up and down buttons. ENGINE ON.

2. Once at the desired height, ENGINE OFF, and take out the paperclip from DLC1, so the car remains at the height from the previous step.

3. Turn IGNITION ON to connect Techstream, but keep ENGINE OFF, and then manually adjust the sensors close to 0mm by checking AHC live values.

Do I ride it around a bit to make sure the front sensors are close enough to 0 mm after being jostled around, before I move on to the rear sensor?

(I am going to take your frequent caveats in to consideration and clean up the sensor mechanism before attempting again, and then check the sensors if I run into any trouble.)

Last edited:

2001LC

SILVER Star

Something I see time and time again in mud. With respect to axle center to fender lip measurements: front 19.5: rear 20.5". I see ~ 5/16" lower, time and time again.

I've measure more than my share of pure stock, no accident, no signs of height sensor adjust. I see: front 19 3/16, rear 20 1/8"". One day I'll try a pure stock and use factory method, than see what I get axle to fender.

I've measure more than my share of pure stock, no accident, no signs of height sensor adjust. I see: front 19 3/16, rear 20 1/8"". One day I'll try a pure stock and use factory method, than see what I get axle to fender.

Thank you IndroCruise!

Just for clarification, after cross-leveling:

1. Perform the height control operation test / active test, using the paperclip in DLC1. This would let me set the desired front hub-to-fender height close to 19.75" simply using the AHC up and down buttons. ENGINE ON.

2. Once at the desired height, ENGINE OFF, and take out the paperclip from DLC1, so the car remains at the height from the previous step.

3. Turn IGNITION ON to connect Techstream, but keep ENGINE OFF, and then manually adjust the sensors close to 0mm by checking AHC live values.

Do I ride it around a bit to make sure the front sensors are close enough to 0 mm after being jostled around, before I move on to the rear sensor?

(I am going to take your frequent caveats in to consideration and clean up the sensor mechanism before attempting again, and then check the sensors if I run into any trouble.)

The answer to the first three questions is "YES".

If the "Active Test" does not work when correctly performed, then it means that the vehicle is trying to tell you that something else is wrong -- in that case, suggest report back and we can try and figure out what is happening. By the way, don't be disturbed by the multiple lights which will appear in the instrument panel during the "Active Test" -- these just indicate that lots of features are being bypassed during the test -- all will return to normal at the end of the test and the AHC ON/OFF button is held down for a few seconds.

The answer to the fourth question is that it is not the Height Control Sensors that need to be 'jostled around' -- but the actual mechanical suspension components and bushes etc, etc, will benefit from a 'drive around the block' to enable them to settle into their new positions after 'cross levelling' adjustments and 'ride height' adjustments have been made. Then a re-measure may suggest some fine tuning. Suggest don't be afraid of a few iterations. On the other hand, 'pursuit of perfection' (or trying to get everything exactly right) often is not worth the effort of continual re-adjustment, meaning no real gain in comfort, performance or clearances. Personal view: I accept hub-to-fender measurements which may be 'out' by 1/8th inch (~3 millimeters), and maybe I am lazy about differences up to 1/4 inch (about 6 millimeters -- but much beyond that is worth paying further attention. Others on this Forum are much more precise.

I don't see how it matters much when you choose to deal with the Rear Height Control Sensor.

On my caveats about condition of Height Control Sensors -- yes, I carp on about that a lot because I often read posts where there is blind reliance on the absence of Height Control Sensor Diagnostic Trouble Codes (DTC's C1711, C1712, C1713) for assurance of good order -- and yet the Sensor readings are widely different, and/or inconsistent with hub-to-fender heights and/or hub-to-fender measurements are not given and/or the vehicle heights are erratic -- which point to problems in the Height Control Sensor circuit whether or not the relevant DTC is present.

The reality is that the absence of these DTC's simply indicate that the circuit (not just the Sensor itself) is sending a voltage signal to the ECU which is within the correct range (equal or more than 0.3 volts and equal or less than 4.7 volts) in the prescribed conditions -- see FSM extract below.

If the Sensor circuit is sending the wrong voltage signal for the height of the vehicle but the voltage signal is still within this range, then the Sensor likely is faulty, or there is an intermittent harness problem somewhere, and the vehicle will behave strangely -- but there may be no DTC. Inspection and testing of the Sensor then is warranted. Inspection is insufficient unless the eyes have a built-in multimeter capability! Testing of the harness and circuit also may be necessary.

Internal cleaning of Sensors may be worth a shot, but in all likelihood, given age and wear, replacement may be the wise course. If so, suggest stay with Toyota/Lexus and AISIN brands and avoid the unhappiness and short life that seems to go with cheap fakes:

Toyota/Lexus Height Control Sensors – Part Numbers:

89405-60012 (Front Right)

89406-60022 (Front Left)

89407-60010 (Rear)

Consider AISIN Sensors -- because AISIN are suppliers to Toyota/Lexus:

Aisin Height Control Sensors – Part Numbers:

HST-020 (Front Right)

HST-021 (Front Left)

HST-026 (Rear)

Last edited:

Something I see time and time again in mud. With respect to axle center to fender lip measurements: front 19.5: rear 20.5". I see ~ 5/16" lower, time and time again.

I've measure more than my share of pure stock, no accident, no signs of height sensor adjust. I see: front 19 3/16, rear 20 1/8"". One day I'll try a pure stock and use factory method, than see what I get axle to fender.

I am guilty as charged @2001LC -- I have been 'channelling' information from posts by @PADDO which I picked up years ago, for example:

Definitive list of AHC maintenance items - https://forum.ih8mud.com/threads/definitive-list-of-ahc-maintenance-items.604577/page-13#post-9855777

If what you have found is a different trend -- then we should be guided by your new data.

I confess that I have never checked heights using the FSM-specified measurements, so I have never reconciled them with the seemingly 'popular' IH8MUD hub-to-fender approximations.

The main thing would seem to be to get the Front and Rear AHC pressures into the correct ranges, whatever height is chosen.

Slightly lower heights would tend to increase the share of the vehicle weight carried by the torsion bars and springs and possibly make AHC pressure management a little easier.

Last edited:

2001LC

SILVER Star

Let's not change the current thinking of frt 19.5" & rear 20.5" just yet.I am guilty as charged @2001LC -- I have been 'channelling' information from posts by @PADDO which I picked up years ago, for example:

Definitive list of AHC maintenance items - https://forum.ih8mud.com/threads/definitive-list-of-ahc-maintenance-items.604577/page-13#post-9855777

If what you have found is a different trend -- then we should be guided by your new data.

I confess that I have never checked heights using the FSM-specified measurements, so I have never reconciled them with the seemingly 'popular' IH8MUD hub-to-fender approximations.

The main thing would seem to be to get the Front and Rear AHC pressures into the correct ranges, whatever height is chosen.

Slightly lower heights would tend to increase the share of the vehicle weight carried by the torsion bars and springs and possibly make AHC pressure management a little easier.

View attachment 3273865

But I would not like to see people changing factory set height sensor, trying to reach those measurement. For one if they move height sensor to raise the rear, which is a sensor lift. Then rear Mpa (pressure) goes up, we want that pressure down near ~6Mpa (5.6 to 6.7Mpa), not up. Pressure up we'll reduce life of the globes, and ride may be funky.

Also wee need to consider, how one makes the measurement. I use a magnetic level attached to the chrome bar in tool kit placed in rear axle center, and mark center of front axle (grease cap). I'm very consistent in points at lip fender, from which I measure. Not so consistent on if engine off or on, as it kicks me out of Tech stream (PITA). Which engine on, provided no issue, comes in the same measurement. So I do first & final cross level measurement engine off. Cross leveling is a piece of cake, provided no accidents that have moved fenders. One other issue that makes measurement difficult or rather different. Is tire protruding out, interring with streight line for tape measure.

I work off rear as pivot point, when making any sensor change. Either I leave height sensor alone, if no reason to think ever been moved. Unless I'm working to change height for a reason.

Pure stock set up. I'll use new OEM LC AHC coils and 30mm spacer. I get ~6.1Mpa (5.6 to 6.7Mpa) at 20 1/8" rear. No change to factory set sensor.

Sensor lift I'll recommend modifying rear coil spring set up, to bring Mpg back down.

Built rig depending on added weight, I may modify coils & T-bars.

Last edited:

TreatSmash

SILVER Star

I spent the better part of a day trying to get 19.5 and 20.5 and finally gave up. It's close enough.Let's not change the current thinking of frt 19.5" & rear 20.5" just yet.

But I would not like to see people changing factory set height sensor, trying to reach those measurement. For one if they move height sensor to raise the rear, which is a sensor lift. Then pressure rear Mpa goes up, we want that pressure down near ~6Mpa (5.6 to 6.7Mpa), not up. Pressure up we'll reduce life of the globes, and ride may be funky.

Also to consider is how one makes the measurement. I use a carpenters level at rear axle center, and mark center of front axle (grease cap). I'm very consistent in points from fender also. Not so consistent on if engine off or on, as kicks me out of Tech stream (PITA). But I do final cross level measurement engine off, before final front Mpa T-bar adjust.

I work off rear as pivot point, when making any sensor change. Either I leave height sensor alone, if no reason to think ever been moved. Unless I'm work to change height for a reason.

Pure stock set up. I'll use new OEM LC AHC coils and 30mm spacer. I get ~6Mpa (5.6 to 6.7Mpa) at 20 1/8" rear. No change to factory set sensor.

Sensor lift I'll recommend modifying rear coil spring set up, to bring Mpg back down.

Built rig depending on added weight, I may modify coils & T-bars.

I am replacing my globes today though and it will probably require another cross balancing and sensor adjustment, so we'll see how it goes.

Hey team, quick question-

Apparently there is a TSB issued by Toyota for seeping shock absorbers.

Would anyone know where I would find that?

Apparently there is a TSB issued by Toyota for seeping shock absorbers.

Would anyone know where I would find that?

Hey team, quick question-

Apparently there is a TSB issued by Toyota for seeping shock absorbers.

Would anyone know where I would find that?

The attachment furthest below may be of interest -- see last page.

However, on an AHC-equipped vehicle, the conventional wisdom is to ensure AHC pressures are within the FSM-specified ranges. Active Height Control (AHC) 'shock absorbers' really are just hydraulic struts. In the Toyota Electronic Modulated Suspension (TEMS) damping is regulated by the Damping Force Control Actuators to which the 'globes' are attached. Weeping AHC 'shock absorbers' may be cured by attention to AHC pressures. If AHC pressures are correct and unless seals have been destroyed by long term overpressure or the body of the unit has been destroyed by underbody rust, then AHC 'shock absorbers' should last a very long time. Life of the vehicle? Maybe. The lower bush and/or the top cushion are likely to collapse long before the 'shock absorber' dies. The AHC so-called 'shock absorbers' are not expected to 'wear out' in the same manner as conventional shock absorbers.

Attachments

Last edited:

The attachment furthest below may be of interest -- see last page.

However, on an AHC-equipped vehicle, the conventional wisdom is to ensure AHC pressures are within the FSM-specified ranges. Active Height Control (AHC) 'shock absorbers' really are just hydraulic struts. In the Toyota Electronic Modulated Suspension (TEMS) damping is regulated by the Damping Force Control Actuators to which the 'globes' are attached. Weeping AHC 'shock absorbers' may be cured by attention to AHC pressures. If AHC pressures are correct and unless seals have been destroyed by long term overpressure or the body of the unit has been destroyed by underbody rust, AHC 'shock absorbers' should last a very long time (life of the vehicle?) and are not expected to 'wear out' in the same manner as conventional shock absorbers.

View attachment 3275129

This is awesome, thank you very very much!

I have given the shock a clean to better gage how much it's coming out and then we'll go from there. The grime on the shock was wet looking (but not wet to the touch) down to the bushing but that could of been 12 months worth of seepage for all i know. AHC oil levels have hardly moved from what I can tell so I'm suspecting a minor seepage that has spread through the grime over time.

Pressures were both 7.2 after a cycle and then in 'N', so they check out all good.

The man at the warrant of fitness testing place said it is blown and needs replacing before he'll give the truck it's sticker - I'm not convinced. Yet.

Thank you for this!

This is awesome, thank you very very much!

I have given the shock a clean to better gage how much it's coming out and then we'll go from there. The grime on the shock was wet looking (but not wet to the touch) down to the bushing but that could of been 12 months worth of seepage for all i know. AHC oil levels have hardly moved from what I can tell so I'm suspecting a minor seepage that has spread through the grime over time.

Pressures were both 7.2 after a cycle and then in 'N', so they check out all good.

The man at the warrant of fitness testing place said it is blown and needs replacing before he'll give the truck it's sticker - I'm not convinced. Yet.

Thank you for this!

The “Vehicle Fitness Tester” or “Inspector” by whatever name in any country would be concerned about suspension damping -- without which there are well-known dangerous effects on stability and control of the vehicle when travelling as well as on braking and steering. So to that extent he is just doing his job – because undamped vehicles are a danger to others and the law in many jurisdictions require that such vehicles be kept off public roads.

However, it is a fair bet that your Tester/Inspector is completely unaware of the nature of the suspension on your vehicle – and that what he is assuming to be a ‘shock absorber’ responsible for damping is not a shock absorber at all, even though it looks like one, and if so, he would be unaware that on your vehicle this device has nothing to do with damping. It is a 'hydraulic strut' used to control the ‘ride height’ of the vehicle.

It may help if you explain the nature of the suspension with some documentation – in particular the attached Toyota/Lexus General Description of the AHC and TEMS systems and how damping works on your vehicle -- and how it is quite different to a conventional suspension – and in particular that the damping is regulated in 16 steps (by the Suspension Electronic Control Unit giving instructions to the Damping Force Control Actuator) in response to road conditions as well as speed, braking, cornering etc -- also with different damping selections, or ‘maps’ -- “COMFORT”, “NORMAL”, “SPORT1”, “SPORT2” -- available to the driver via the switch on the centre console.

This is the on-line reference for this Toyota document:

LC100 Workshop Manual - https://lc100e.github.io/,

then scroll down through the index panel on the LHS of the opening page:

+ New Car Features

+ CHASSIS

+ Suspension

+ Active Height Control and Skyhook TEMS

Scrolling to “Repair Manual” reveals settings, repair information etc. For example:

LC100 Workshop Manual - https://lc100e.github.io/

+ Repair Manual

+ SUSPENSION AND AXLE

+ ACTIVE HEIGHT CONTROL SYSTEM

+ ON-VEHICLE INSPECTION

Obviously you know your way around the system because you have measured and quoted AHC pressures – Front at 7.2Mpa looks good, Rear at 7.2Mpa looks a little high.

It will take only a very tiny amount of AHC Fluid to make the ‘shock absorber’ look like it is weeping. If there was a difference visible at the AHC Tank due to a weep or an external leak, then it would be very visible, including on the garage floor!

By the way, suggest be aware that AHC pressures tell nothing about the condition of ‘globes’ -- correct AHC pressures does not mean that 'globes' are good -- and ‘globes’ in poor condition certainly will result in poor damping.

AHC Fluid can 'hide' within the 'globes' if the internal membranes have failed, allowing nitrogen to vacate and allowing the space behind the membrane to be occupied by AHC Fluid -- then there will be a noticeable drop in Fluid level at the AHC Tank. So be suspicious of 'globe' failure if it seems necessary to add AHC Fluid and no external leaks can be found. This situation will NOT be accompanied by a drop in AHC pressures. AHC pressures are related only to the share of the vehicle weight carried by the so-called AHC 'shock absorbers' (actually hydraulic struts!) versus the share of the vehicle weight carried by the Front torsion bars and Rear springs -- nothing to do with the condition of the 'globes'.

The test for the overall condition of the four ‘globes’ (called ‘Gas Chambers’ in the Factory Service Manual -- FSM, referred to as ‘spheres’ on some forums, also called ‘accumulators’ on many parts websites) is revealed at the following reference.

LC100 Workshop Manual - https://lc100e.github.io/

+ Repair Manual

+ SUSPENSION AND AXLE

+ DAMPING FORCE CONTROL ACTUATOR

+ ON-VEHICLE INSPECTION

Finally, if the AHC Fluid has not been changed at recommended intervals (Owner's Manual: 60,000 miles = 100,000 kilometres or six years in USA but five years in Australia -- but twice as often is better for system longevity), then suggest acquire several 2.5 litre cans of AHC Fluid -- Part No. 08886-01805 -- via your local Toyota dealer and do this maintenance. It is not a difficult job. Ancient dark sludgy AHC Fluid contributes to poor damping performance. Current cost of a 2.5 litre can of AHC Fluid in Australia is around AUD32.50 -- cost in New Zealand may reflect a different market.

Attachments

Last edited:

Wow!!The “Vehicle Fitness Tester” or “Inspector” by whatever name in any country would be concerned about suspension damping -- without which there are well-known dangerous effects on stability and control of the vehicle when travelling as well as on braking and steering. So to that extent he is just doing his job – because undamped vehicles are a danger to others and the law in many jurisdictions require that such vehicles be kept off public roads.

However, it is a fair bet that your Tester/Inspector is completely unaware of the nature of the suspension on your vehicle – and that what he is assuming to be a ‘shock absorber’ responsible for damping is not a shock absorber at all, even though it looks like one, and if so, he would be unaware that on your vehicle this device has nothing to do with damping. It is a device used to control the ‘ride height’ of the vehicle.

It may help if you explain the nature of the suspension with some documentation – in particular the attached Toyota/Lexus General Description of the AHC and TEMS systems and how damping works on your vehicle -- and how it is quite different to a conventional suspension – and in particular that the damping is regulated in 16 steps (by the Suspension Electronic Control Unit giving instructions to the Damping Force Control Actuator) in response to road conditions as well as speed, braking, cornering etc -- also with different damping selections, or ‘maps’ -- “COMFORT”, “NORMAL”, “SPORT1”, “SPORT2” -- available to the driver via the switch on the centre console.

This is the on-line reference for this Toyota document:

LC100 Workshop Manual - https://lc100e.github.io/ , then scroll down through the index panel on the LHS of the opening page:

+ New Car Features

+ CHASSIS

+ Suspension

+ Active Height Control and Skyhook TEMS

Scrolling to “Repair Manual” reveals settings, repair information etc. For example:

+ Repair Manual

+ SUSPENSION AND AXLE

+ ACTIVE HEIGHT CONTROL SYSTEM

+ ON-VEHICLE INSPECTION

Obviously you know your way around the system because you have measured and quoted AHC pressures – Front at 7.2Mpa looks good, Rear at 7.2Mpa looks a little high.

It will take only a very tiny amount of AHC Fluid to make the ‘shock absorber’ look like it is weeping. If there was a difference visible at the AHC Tank due to a weep or a leak, then it would be very visible, including on the garage floor!

By the way, suggest be aware that AHC pressures tell nothing about the condition of ‘globes’ -- correct AHC pressures does not mean that 'globes' are good -- and ‘globes’ in poor condition certainly will result in poor damping.

The test for the overall condition of the four ‘globes’ (called ‘Gas Chambers’ in the Factory Service Manual -- FSM, referred to as ‘spheres’ on some forums, also called ‘accumulators’ on many parts websites) is revealed at the following reference.

LC100 Workshop Manual - https://lc100e.github.io/

+ Repair Manual

+ SUSPENSION AND AXLE

+ DAMPING FORCE CONTROL ACTUATOR

+ ON-VEHICLE INSPECTION

Finally, if the AHC Fluid has not been changed at recommended intervals (60,000 miles = 100,000 kilometres or six years in USA but five years in Australia -- but twice as often is better for longevity), then suggest acquire several 2.5 litre cans -- Part No. 08886-01805 -- via your local Toyota dealer and do this. It is not a difficult job. Ancient dark sludgy AHC Fluid contributes to poor damping performance. Current cost of a 2.5 litre can of AHC Fluid in Australia is around AUD32.50 -- cost in New Zealand may reflect a different market.

Thank you so much for your time - I feel I should pay you!

Armed with this awesome information I'm going to take the truck back right now, explain what you have explained and get them to try again.

I'll report back on the outcome.

Thank you!

2001LC

SILVER Star

New globes should not changes either cross level or sensor (height). But pressure may change.I spent the better part of a day trying to get 19.5 and 20.5 and finally gave up. It's close enough.

I am replacing my globes today though and it will probably require another cross balancing and sensor adjustment, so we'll see how it goes.

Unless you had changed/adjusted the sensors. In which case, I'd read the pressures, after bleeding air from system. Than I'd adjust rear sensor, to get near ~6.2Mpa rear. When happy with rear pressure, then adjust front sensors to get a minimum of 3/4" (I like 15/16" minimum) rake. As you adjust front sensors, you may need to adjust rears sensor again just tad. If happy with cross level & rake, than tweak T-bars evenly to get the 6.9Mpa. Drive and re-tweak as needed. One note: Oil temp goes up with each raise and lowering. This will change level in reservoir, and can effective Mpa readings. So come back the next day, and tweak with oil sensor connected. Shoot for 80f to 90F. Mpa reads don't seem to change much, sensor unplugged or plugged in, once we hit the target Mpa. Provided we don't get fluid to hot.

Yesterday on a 07LX w/300K miles. I just installed new globes , fresh AHC fluid, new springs and 30mm spacer. Rear came in at 6.2Mpa at RR&RL 20 1/8" It did not have full tank of fuel, so I added two 5 gallon jug of liquid as ballast, over gas tank. No 3rd row seats, but some gear in cargo area. I adjust T-bars to get 6.9Mpa at FL 19 5/16" FR 19 3/16" (recent accident FR, signs of accident on RH side also). FL height control sensor was -0.5. I adjust FL sensor. Which was already riding in bottom of slide. By extending turnbuckle ~.5mm. FL reading drop just a tad to -0.4" . It's head to east coast today. I'll catch on return trip to west coast, and tweak adjustments, base on feedback from driver as he passes back through Denver this summer.

Oil Temp sensor unplugged (-22F)

The answer to the first three questions is "YES".

If the "Active Test" does not work when correctly performed, then it means that the vehicle is trying to tell you that something else is wrong -- in that case, suggest report back and we can try and figure out what is happening.

I already had 19.5" for my front measurements, so I went ahead and tried the Active Test. The car height did not change when I used the AHC up and down buttons. I did hear a noise from the front driver side when I pressed the up button, but I couldn't tell if it was the accumulator or globe. Here is a video:

Also of note, when I observed the AHC fluid reservoir, it was at the correct level at N, but it seemed that the fluid was a bit bubbly, that there was a bubbly SQUIRT sound from the tank at the very end of the adjustment, and the sound of the pump ended up with a slight high-pitched noise which I imagine is what it sounds like when people on here have talked about 'cavitation' sounds from the AHC pump.

Although clearly something is wrong, I do not have any DTCs, and the car is still making full L/N/H height adjustments, as well as a definite difference in softness/pushness/bounciness of the ride going from Sport -> Comfort+. Previously I had flushed the AHC fluid and the fluid from the accumulator had been a bit bubbly, but at the end of the bleed I was getting fresh fluid from all 5 bleed points (and 10+ gradations on the test, although I know now that testing that is premature). After the flush there was also a definite difference in the car being less rigid.

Anyways, after failing the Active Test, I went ahead and tried zeroing out the sensor heights anyway, and ran into another problem: rear sensor height is in the negative despite lowering adjustment all the way to the bottom of the slider.

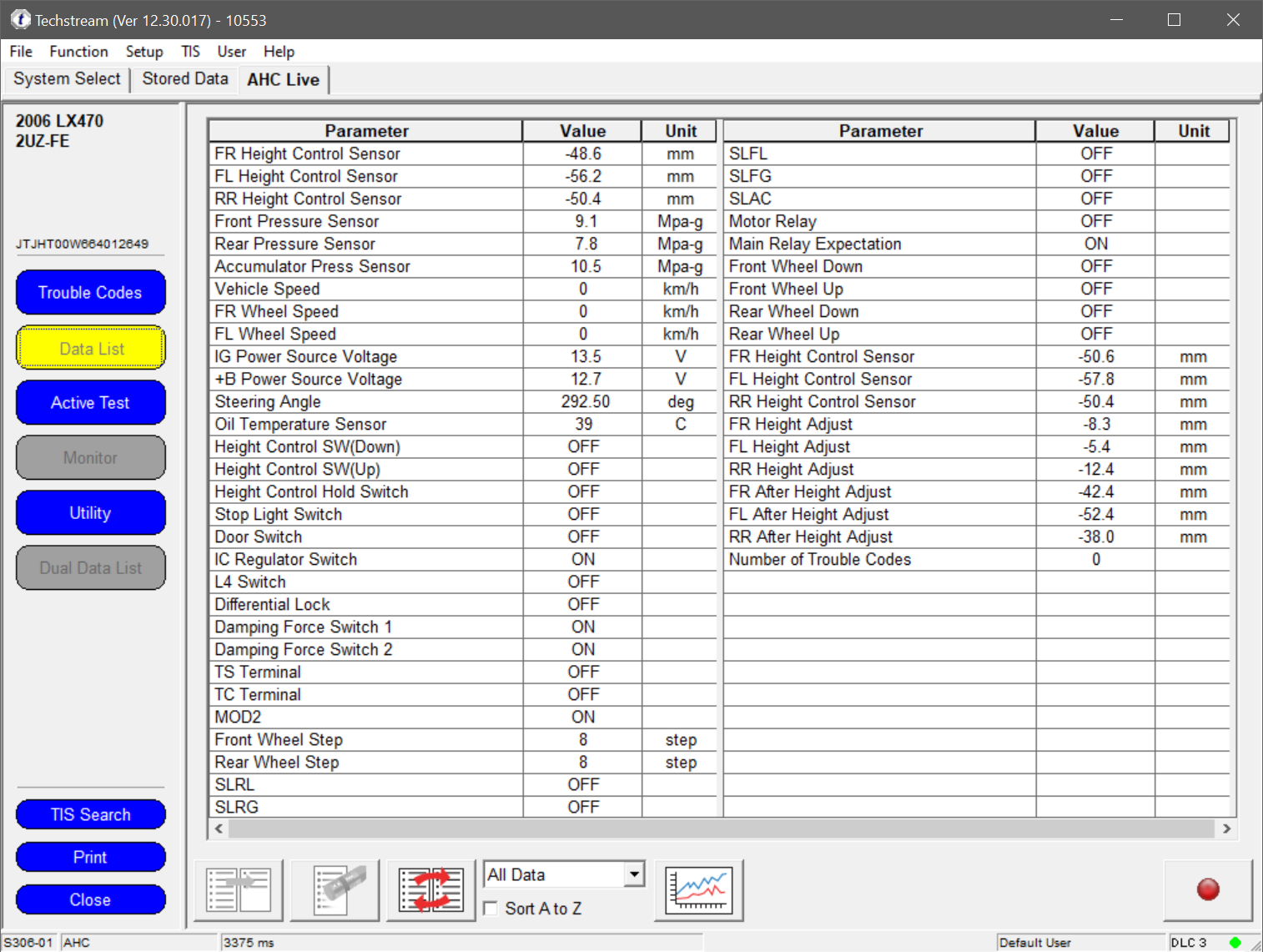

I then drove around the block and when I parked again, the sensor heights had changed, and now the truck was sitting lower: 19.25 in the front, 19.75 in the back (see first image below).

Then I still went ahead and tried cycling through the height control just to see what pressures I would get, and those are below. (Goes N > L > N > H > N):

N

L

N

H

N

What next?

TreatSmash

SILVER Star

We'll see, I could only get 3/4 globes off and totally wrecked the 4th one trying so I have to take it to the dealership (Lexus they have a good AHC guy here) on Monday.New globes should not changes either cross level or sensor (height). But pressure may change.

Unless you had changed/adjusted the sensors. In which case, I'd read the pressures, after bleeding air from system. Than I'd adjust rear sensor, to get near ~6.2Mpa rear. When happy with rear pressure, then adjust front sensors to get a minimum of 3/4" (I like 15/16" minimum) rake. As you adjust front sensors, you may need to adjust rears sensor again just tad. If happy with cross level & rake, than tweak T-bars evenly to get the 6.9Mpa. Drive and re-tweak as needed. One note: Oil temp goes up with each raise and lowering. This will change level in reservoir, and can effective Mpa readings. So come back the next day, and tweak with oil sensor connected. Shoot for 80f to 90F. Mpa reads don't seem to change much, sensor unplugged or plugged in, once we hit the target Mpa. Provided we don't get fluid to hot.

Yesterday on a 07LX w/300K miles. I just installed new globes , fresh AHC fluid, new springs and 30mm spacer. Rear came in at 6.2Mpa at RR&RL 20 1/8" It did not have full tank of fuel, so I added two 5 gallon jug of liquid as ballast, over gas tank. No 3rd row seats, but some gear in cargo area. I adjust T-bars to get 6.9Mpa at FL 19 5/16" FR 19 3/16" (recent accident FR, signs of accident on RH side also). FL height control sensor was -0.5. I adjust FL sensor. Which was already riding in bottom of slide. By extending turnbuckle ~.5mm. FL reading drop just a tad to -0.4" . It's head to east coast today. I'll catch on return trip to west coast, and tweak adjustments, base on feedback from driver as he passes back through Denver this summer.

Oil Temp sensor unplugged (-22F)

View attachment 3275467

That being said I still went from 7 to15 graduations with just 3 globes.

I didn't expect it to effect the rake or the height of the ride, but since I am replacing the globes and flushing I was planning on going ahead and cross leveling and adjusting the sensors as needed as well.

I'm not really too worried about anything until I get that 4th globe in.

2001LC

SILVER Star

I suppose taking to Dealership is and option.We'll see, I could only get 3/4 globes off and totally wrecked the 4th one trying so I have to take it to the dealership (Lexus they have a good AHC guy here) on Monday.

That being said I still went from 7 to15 graduations with just 3 globes.

I didn't expect it to effect the rake or the height of the ride, but since I am replacing the globes and flushing I was planning on going ahead and cross leveling and adjusting the sensors as needed as well.

I'm not really too worried about anything until I get that 4th globe in.

But if you want to give another shot, at removing the stuck globe today.

Harbor Freight has a forged open end wrench set. I use the 36mm form the kit. It's a very tight fit, so I tap wrench onto the globes nut for a very secure fit. Than for added leverage, I use a pipe on 36mm wrench handle. If only corners of globes nut round, you may still get a good hold on flats.

If nut now to round, which I've not seen happen (knock on wood).

My next move(s), May be:

- A cold chisel. With great care in placement, so not to damage anything other than globe.

- A chain wrench. Which could prove to difficult to get on and hold globe.

- Drill and run a steel rod though as a handle.

- If all other attempts fail. I'd remove the actuator and take to the bench.

Similar threads

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)