Damn, that chart is thorrough! But, again this is rather speculative, the idea as I understood it was that the pulse-effect, like that in a n/a engine, coming from the dump valve caused the issues, not the elbow or bend itself. The recommendation was that the dump valve was routed 12-18" down the exhaust by itself, before it joined the rest. Preferably not joining at all.

If I follow this correctly, as that I read page 1 then skipped to page 4... I don't have too much time, you're referring to the wastegate (aka Dumpvalve, apparently)... and having it's exhaust exit recirculate into the main system later down the downpipe. This is what's known as a Divorced Down Pipe and is extremely effective at keeping exhaust moving down the system by reducing turbulence. A popular thing to do is to give the wastegate's outlet it's own muffler and not bother recirculating it... motor cycle mufflers work well, apparently. Keep in mind that an open wastegate to atmosphere is essentially no exhaust system at all... so when that sucker cracks open, it's gonna be LOOUUUDDDDD!

As for the intercooler itself, and I don't know if it was covered in the 3 pages I skipped (if it was please forgive me

), you want the smallest intercooler that will meet your requirements, then add a few percent to that size. If it were me, I'd be calling up a nationally reputable tuning shop and explaining what you have and what you need. I've heard good things about Extreme Turbo Systems, Titan Motorsports, and Wide Open Throttle Motorsports in the states, but RCTS is who I would phone, being as that I'm in Canada.

As for the side/side or same side intercooler, that depends on how your intake is positioned relative to your turbo's compressor outlet. Use the intercooler that produces the least amount of pipe routing because each bend will cut engine response and increase heat soak from engine tempratures.

Ceramic coat the hell out of everything that gets heated. Especially the turbine section of the turbo... it gets smokin' hot. You want the heat to go down the exhaust pipe not into the engine bay. It's not uncommon for a turbine to glow red after some hard driving; ceramic coating, a turbo blanket and exhaust wrap on the exhaust manifold (and ceramic coating) will decrease engine bay temperatures substantially by keeping hot metal and air seperate. If you have the engine apart, do not ceramic coat the combustion chamber without doing the piston, or vice versa, as that one without coating may overheat under heavy load. I've seen it done may times on performance gas engines, I don't see how it wouldn't benifit a diesel to keep the heat in the exhaust instead of the head and piston (especially if the engine isn't equipped with piston squirters).

Ceramic coat inside and outside the intercooler pipes so that they don't heat soak. My supra's intercooler pipes are bare aluminum and remain scalding hot for loooooooong after the car's shut down. A friend of mine has his ceramic coated, you can touch them while the engine's running just after a lap of a road course.

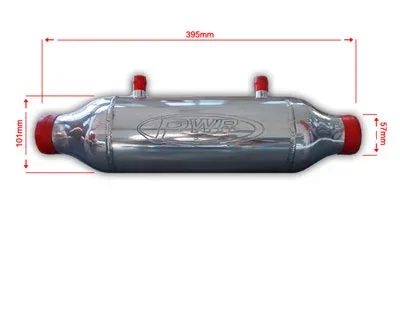

A water/air IC may be prime in this application if engine cooling is a serious issue and engine bay space is tight... you can remote mount the water system's radiator and leave more incoming air to cool the engine's radiator, as opposed to having an air to air IC and blowing the cool incoming air over the smoking hot IC then onto the even hotter radiator. Water/air IC's are also more compact and don't require any airflow to the inlet air's exchanger. They're not used often in road cars because air/air IC's have a higher horsepower potential and are more efficient at the high speeds a road car usually travels at. Most water/air IC's have limits around 500hp.

Anyway, on the assumption that this is a Toyota turbo you're using, CT12, 12A, 20, or 26 based, there's alot of highflow turbo elbows and downpipes available, as that the former came on the 1JZ-GTE, the 2JZ-GTE, the 3S-GTE/22R-TE, and the 7M-GTE. The turbo you have will have the model number stamped on the compressor section, but I honestly have no idea what it would have

I don't know if the EGT thing was figured out, but anyway, lowering your EGT doesn't have much, if any, effect on spool time or boost threshold for a turbo. It does however make the turbo last substantially longer because the center section sees less heat, the turbine section retains less heat, oil isn't as likely to coke in the passages and bearings, and it helps keep the seals lasting long and running strong. Lower exhaust gas tempratures are good for pretty much everything if the engine's tuning and performance are maintained. Cooking a turbo to death with exhaust gases unneccesarily 200*F higher than they could be is just wasting money and horsepower.

Anyway, I hope this helps in some way. Good day to you.