Very interested in all of this, since I've just decided to do a nice job on a manifold refresh/refurb as one last turd-polish to get a few more years out of the old 2F before, probably, a newer engine which I'd rather build with plenty of time on the 2F's clock. The last manifold job (which I half-assed concurrently with a desmog on a nickel and dime budget in 2011) got me *almost* 40k of trouble-free service, but boy it got worse *fast* this past year. I think it was the 80mph, 7000 ft long hauls to/from Moab in 2019...it's amazing what a mechanically healthy 2F with a desmog will do with 33s and 3.70 gears, even with wonky timing and leaks, but that trip definitely took a toll on every single part that wasn't at 100% before we left.

As far as the manifold issues go, it finally started putting soot on the side of the engine under the leaking exhaust horn joint, which moved this up the 'ol repair list a few spots to 'this winter.' So, I'm happy to elbow my way into this discourse, considering this vested interest...

Anyway: what do folks think the best approach is, for a stock, machined-flat intake/exhaust pair, considering a desmog, a desire for lack of hassle on reassembly and desired longevity of the fix, for the following:

- Choice of manifold gasket -- last I heard, if you looked up a 'generic' Felpro for an FJ60, it's the same exact part as Toyota's OEM gasket, but in a different box, and it can be cheaper, sometimes. Any other Deep Lore on this? I fell for the Remflex hype in 2011, the first time I tried to fix my manifold leak, and was highly unimpressed, and the Felpro/OEM one I used after that lasted great in spite of janky half-washer BS to avoid having to get things machined.

- Hardware, both in terms of source/shopping list if you just want to replace all the rusty old crap, as well as whether to monkey with the stock combination of studs with nuts and bolts straight into the head. I remember feeling like 'there has to be a better way!' on reassembly back in 2011, like maybe ditching all of the studs, for same-spec bolts, but I didn't have an impact gun or know how easy it is to drop the skid plate and let the exhaust droop back then, or all sorts of other tricks which seem like they'd make things comparatively easy. Ten years of wrenching experience and better tools are guaranteed to make everything go smoother, considering I haven't crippled myself doing something stupid so far.

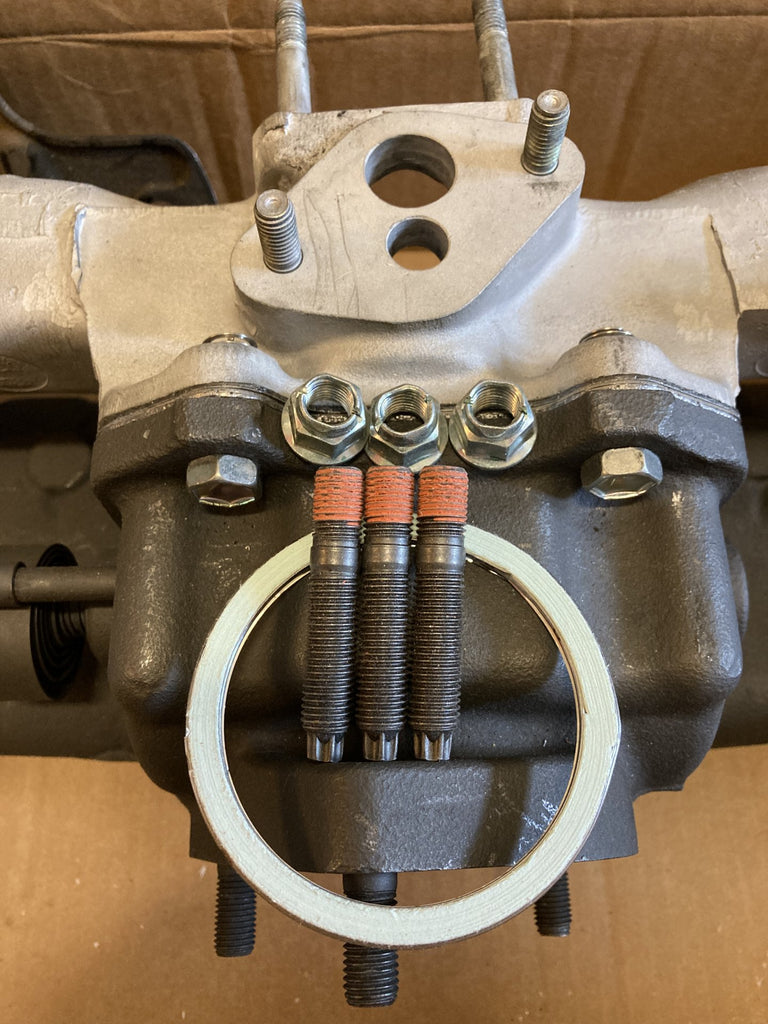

- If the goal is to not have to do the dang job twice, what's the consensus on the full parts list? I'm thinking as deep as exhaust horn rings, gaskets for *a choice* of heat riser solution/replacement.* The main goal here is to have the gaskets and all the moving parts between the exhaust and intake sorted and torqued together before I bring them to a shop to get milled, and I'd like the least goofing around to achieve that.

* Big side note: I think I have a MAF stainless steel partial-diverter plate with just a fixed, curved side and a small opening in place of the stock flapper setup, which has worked flawlessly for me, but I think the new manifold has a stock flapper I could refurbish as well). I feel like it'd be silly not to spent a little money to get something better than either of the donor setups if I'm redoing *everything*.

- While we're at it, what's good to deal with while that side (and, really, the whole top/both sides of the engine) are exposed, what are the absolute must-do jobs/checks?

Here's what I have in mind already:

-- Valve adjustment (duh)

-- Bite the bullet and replace every old/janky coolant hose/clamp

---- Radiator/cooling system flush if I'm replacing the bottom-end, annoying hoses (which I would) finally, right?

---- Does anybody have part numbers handy for reasonably priced (vs. trial-and-error'd from the local part store's generic close-enough hoses/trimmed from stuff off the shelf) heater valve hoses? The ones right up by the firewall? I'm absolutely unhappy with the janky trash I made work up there, when I 'solved' that coolant leak circa 2016. I'd be fine spending as much as $50 on the hoses if they're *actually* the right size/shape, but I'd rather spend $30 and a couple of afternoons of research back and forth at O'Reilly down the street than spend $100 on genuine Toyota hoses, if those are the two extremes. I already spent the big bucks on OEM main radiator hoses from Spectre which are just waiting to go in, so I feel like I paid my toll to the TEQ troll, vis a vis rubber hosing.

-- Core out my definitely funky/kinda clogged cat for the time being, or put a 'test pipe' in, since I'm not planning to put big money into the stock exhaust, and I'm indefinitely out of needing to worry about emissions/inspection. I figure getting it flowing freely and not having any upsteam leaks/vacuum problems and being able to finally get the timing set will make it *less* polluting than it is now with whatever function is left in the remaining intact catalytic substrate. I also don't feel bad, knowing how little this thing gets driven overall. Still don't love this, but I can't justify 'properly' dealing with the cat if I'm going to be putting some kind of V8 with custom, close-to-emissions-legal exhaust in when I ditch the 2F. I'm feeling like I'd rather commit light EPA crime and destroy my already ruined cat vs. spending $100 on a test pipe from MAF, unless my old one is worth a good fraction of that. Opinions?

Anything else obvious? I also have a badly adapted saginaw bracket in place of my original smog pump, and am thinking of rolling a permanent better bracket solution into the manifold work, since that's the side of the engine that'll be bare for a few weeks....but that's a whole other thread/line of research.