DanS HJ-45

SILVER Star

- Thread starter

- #501

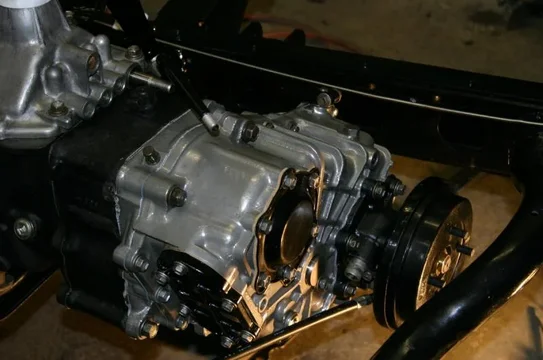

Since it was easy and accessible, I figured it would be a good idea to check the 5th gear engagement. I cut a couple bits of PVC pipe so that I could bolt the 5th gear housing onto the back of the transmission, then it shifted the way it should (without that, when you shift into fifth the housing gets pushed away from the transmission).

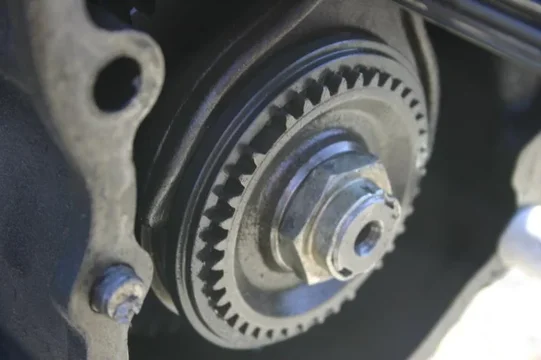

Any gear other than 5th...

And 5th gear engaged.

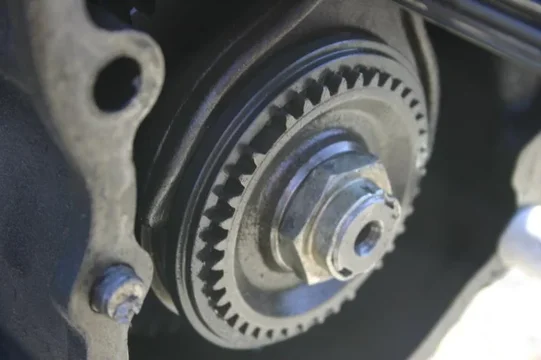

Any gear other than 5th...

And 5th gear engaged.