Dan,

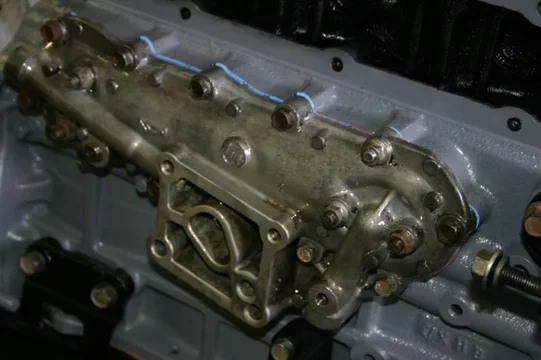

In adition to all your other talents, it appears that 'photographer' will have to be near the top; those photos of the injector lines are pure artwork. If my wife would let me I would blow that shot up to 3' x 5', frame it with a lovely welded picture frame (with baked-on enamel, of course) and hang it over the fire place.

Josh

In adition to all your other talents, it appears that 'photographer' will have to be near the top; those photos of the injector lines are pure artwork. If my wife would let me I would blow that shot up to 3' x 5', frame it with a lovely welded picture frame (with baked-on enamel, of course) and hang it over the fire place.

Josh