1. I replaced my pump when I had the head off along with all trans and PS related hoses. This job is much easier to do now that you have clearance. Yes, bleeding is simply turning the steering wheel stop to stop. I believe the manual specifies bumping up to the stop and holding momentarily.I didn't update the thread for a longer time. The head is still in the shop and now it is already three weeks there. This is what I was doing recently:

- Cleaned all the pistons tops. After cleaning of the pistons I was rotating the crankshaft and cleaning with oily rag until the rag was really clean. It is not perfect but I will leave it as it is. This was the biggest PITA job so far on the project. I spent maybe 6 to 8 hours cleaning the block which I think is too much. The reason is that I am not using any power tools just my hands.

- I unwrapped the engine wire, this was the second worst PITA job on the project so far

. Fortunately the wires are fine and not damaged. I bought some heat tape and will put it on the wire tomorrow.

- I completed all the vacuum hoses from intake and throttle body. I had to order couple of bigger hoses from CDAN. Other then that I used five sets of the small hose's sets.

- The brake booster vacuum hose was replaced. At the first sight I was thinking that it was overkill to replace it but under closer inspection the hose is really hard as rock on the intake side. Good idea to replace that.

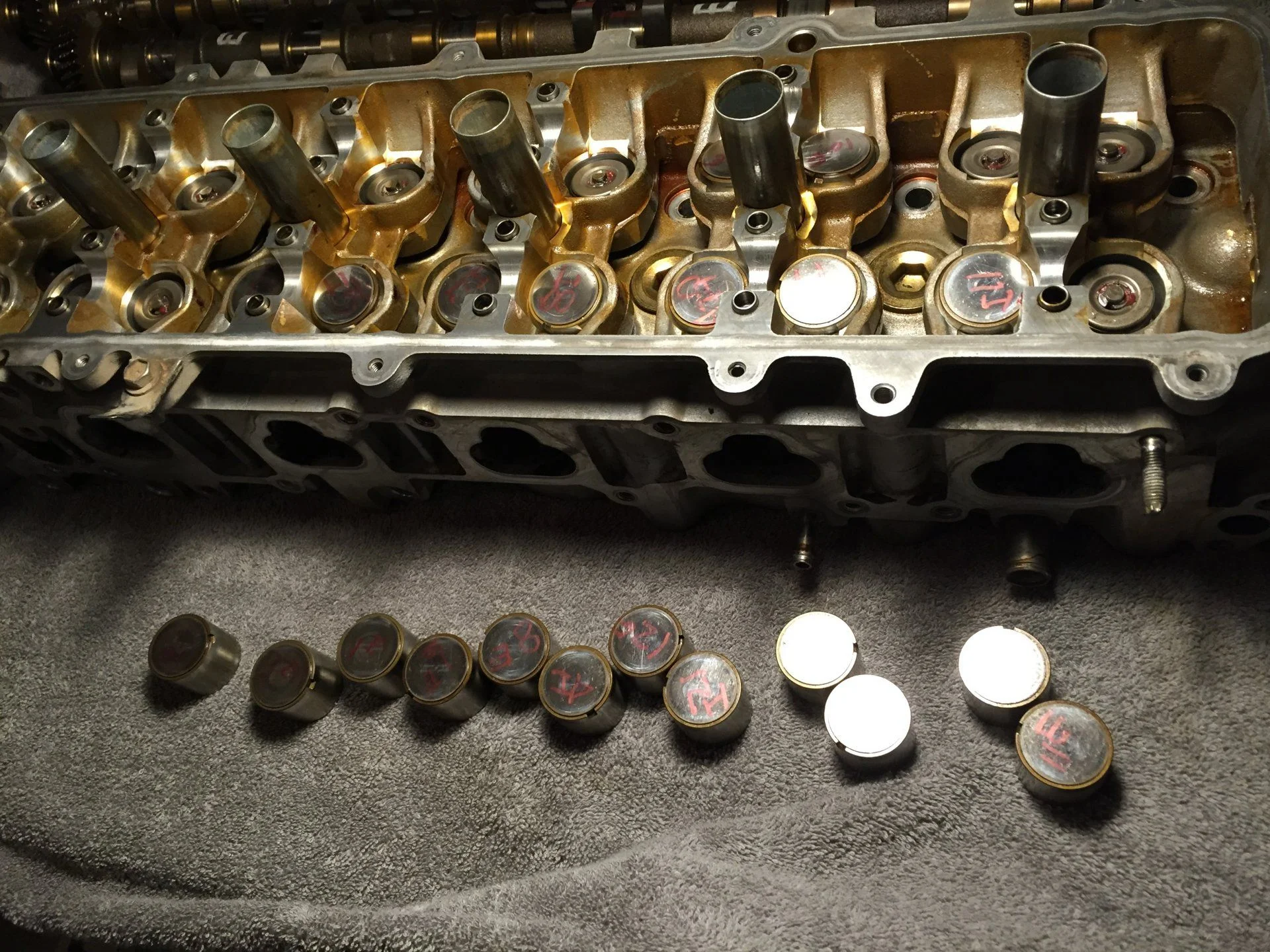

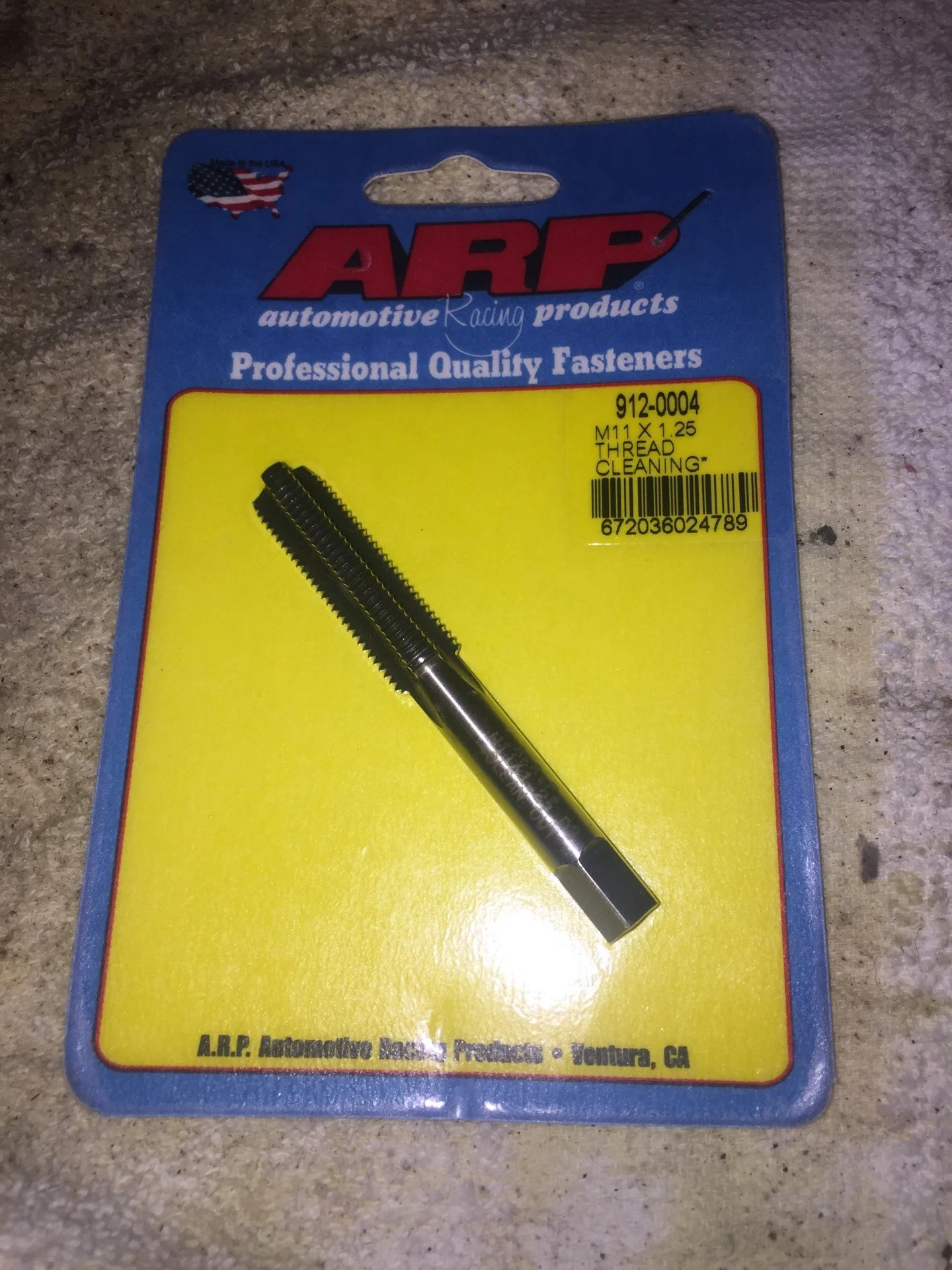

- Today I took of the engine oil cooler and replaced the gaskets. Unfortunately I don't have the pictures as my iphone died but there was some serious slug there. The cooler housing on the block was so dirty that it really surprised me. Not a big job and actually I used the torque wrench for the first time to put the cooler back. I replace all three gaskets.

Couple of questions as always.

- The power steering pump was leaking before so I ordered the hoses from phhkit web site and the gasket kit from CDAN. I don't have proper stands right now to properly bleed the system (AFAIK the bleeding is just turning the wheels left to right). What do you suggest - shall I do it right now when everything is nice open or do it later ?

- The A/F cooler - I have 1997 Land Cruiser with A/F cooler. When I look into the manual the connection of the hoses is directly from the transmission to the cooler. My is different - first the hose is going to the radiator then from radiator to the A/F cooler. I don't know if this is something special or not.

- I just realized that I am missing the idler pulley on the alternator side - what do you suggest ? Shall I buy it or run without it. I have seen some people going without the idler and without having any issues.

2. Your trans cooling system is the usual set up.

3. Why not install the idler pulley? It can't cost that much.

[/hijack]

[/hijack]