- Thread starter

- #201

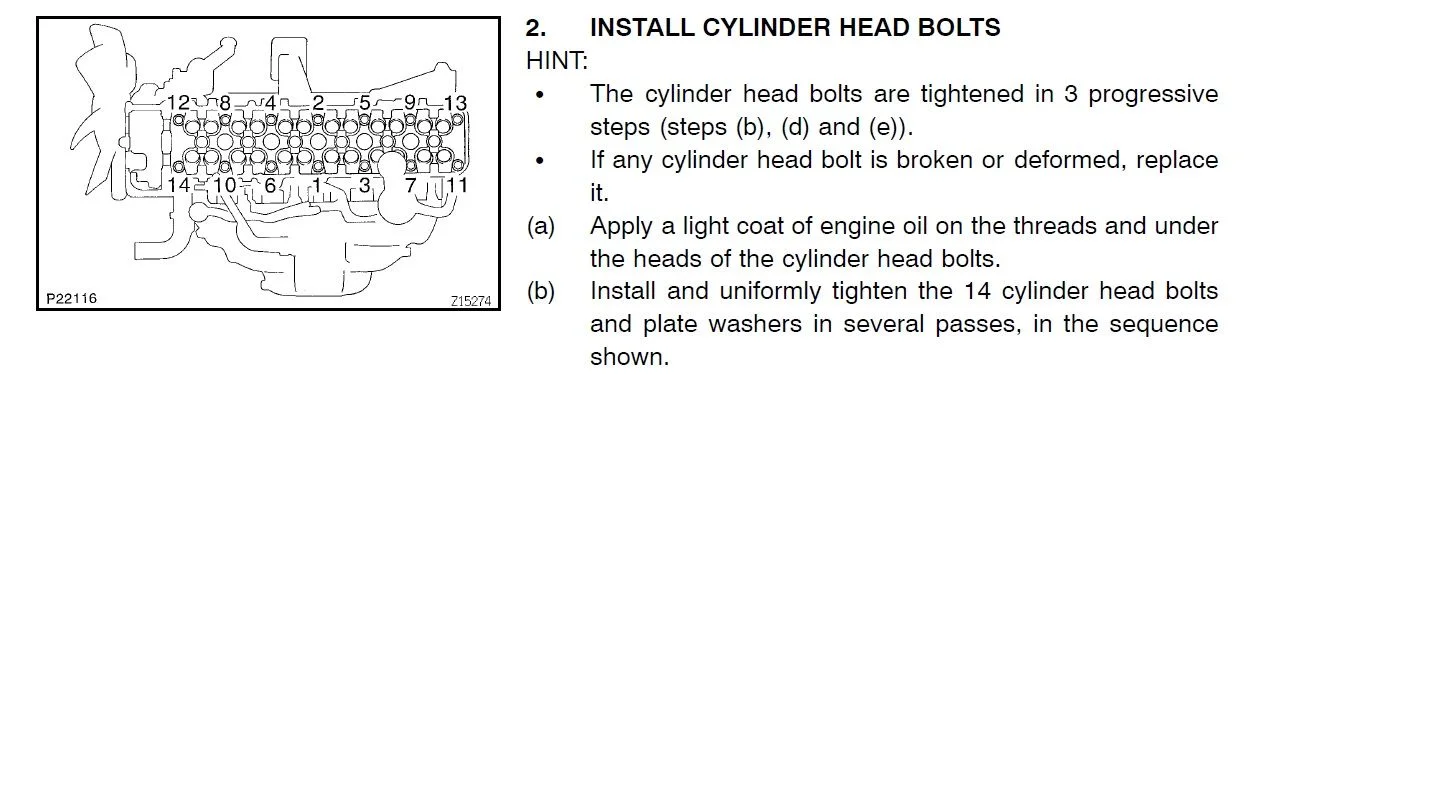

Well I am complete noob and I admit it, but everybody mentions that the meeting surface on the head and the block itself should be clean clean clean. I am even having gloves to not leave marks on the head.Don't obsess about cleaning stuff. It doesn't matter and nobody will see it.