Possibly for the FAQ:

This week I installed the Toyota Hand Throttle in my 96 LC so I can keep the RPM up for winching, jump-starting, and in my immediate need, keeping the RPM up while allowing my LC to warm up and circulate distilled water for a coolant flush sitting in the driveway.

I purchased this kit:

GENUINE Toyota Land Cruiser 80 Series Hand Throttle Kit OEM

He shipped right away and I had it within 5 days of ordering. There may be others out there, but on a quick search, I could not find it in NA or on partsouq. There's one vendor that claims to have them, but I will not risk doing business with them.

The part numbers included are:

78410-60090 Cable

78402-60030 Knob

90179-14032 Nut

This was literally a 15 minute bolt in, even with my "time adjustment" allowed for. (X2 and add 30)

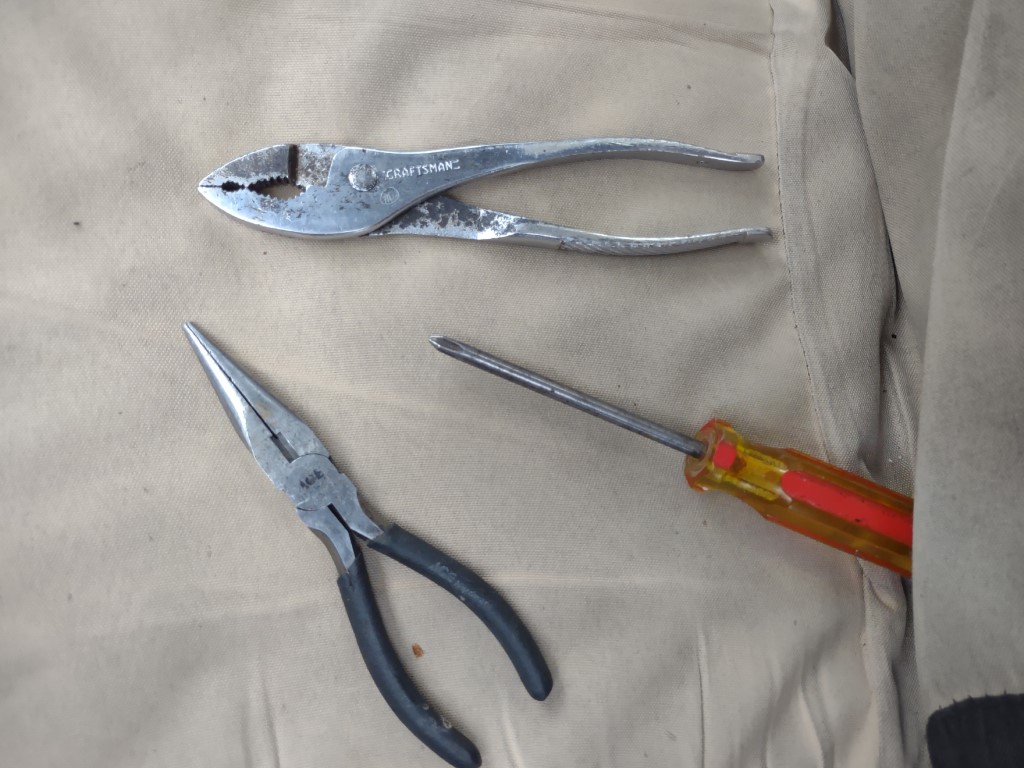

Tools needed:

#2 Phillips screwdriver

6" Needle Nose Pliers

8" pliers

Headlight (for your head)

My 96 already had the proper pedal assembly and bracket that has the attachment for the hand throttle.

If yours does not, you may have to purchase a pedal assembly from a part-out, as I am not sure they are available as new.

Installation Steps:

1) Read EVERYTHING before doing ANYTHING!

2) I noticed that the "throw" of the cable assembly is only about 3/4". I was expecting a throw of about 3". The short throw is absolutely correct.

3) Take note of the current idle RPM of you engine prior to installation, when warmed up (should be about 650)

4) Remove the (4) Phillips head screws from the lower instrument panel finish. Note the length of the screw removed from each location in case they are different lengths.

5) Pop the top few pins from the lower instrument panel finish and gently pull the panel down away from the steering column. You do NOT need to unhook the hood and gas fill door cables.

6) Remove the black plug in the panel where the throttle cable will go by squeezing the two tabs on the back of the plug with your fingers. Be aware that when it comes out it pops out quickly and may ends up under the truck.

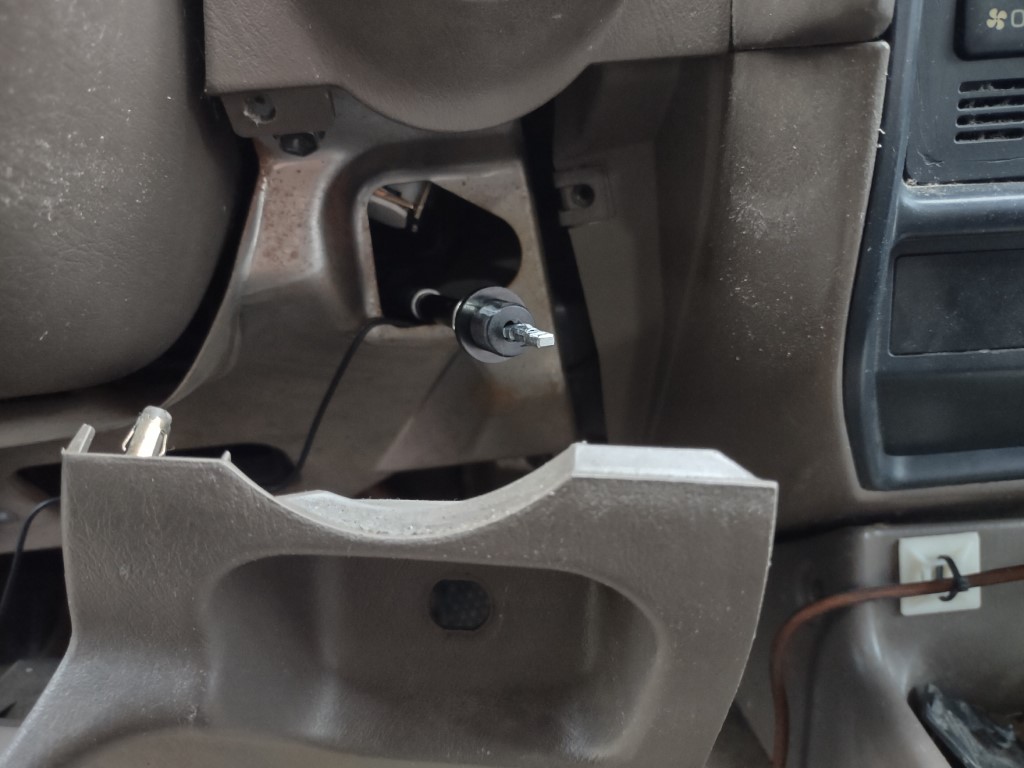

7) Slide the cable assembly into the hole in the steel crash plate in the dash.

This week I installed the Toyota Hand Throttle in my 96 LC so I can keep the RPM up for winching, jump-starting, and in my immediate need, keeping the RPM up while allowing my LC to warm up and circulate distilled water for a coolant flush sitting in the driveway.

I purchased this kit:

GENUINE Toyota Land Cruiser 80 Series Hand Throttle Kit OEM

He shipped right away and I had it within 5 days of ordering. There may be others out there, but on a quick search, I could not find it in NA or on partsouq. There's one vendor that claims to have them, but I will not risk doing business with them.

The part numbers included are:

78410-60090 Cable

78402-60030 Knob

90179-14032 Nut

This was literally a 15 minute bolt in, even with my "time adjustment" allowed for. (X2 and add 30)

Tools needed:

#2 Phillips screwdriver

6" Needle Nose Pliers

8" pliers

Headlight (for your head)

My 96 already had the proper pedal assembly and bracket that has the attachment for the hand throttle.

If yours does not, you may have to purchase a pedal assembly from a part-out, as I am not sure they are available as new.

Installation Steps:

1) Read EVERYTHING before doing ANYTHING!

2) I noticed that the "throw" of the cable assembly is only about 3/4". I was expecting a throw of about 3". The short throw is absolutely correct.

3) Take note of the current idle RPM of you engine prior to installation, when warmed up (should be about 650)

4) Remove the (4) Phillips head screws from the lower instrument panel finish. Note the length of the screw removed from each location in case they are different lengths.

5) Pop the top few pins from the lower instrument panel finish and gently pull the panel down away from the steering column. You do NOT need to unhook the hood and gas fill door cables.

6) Remove the black plug in the panel where the throttle cable will go by squeezing the two tabs on the back of the plug with your fingers. Be aware that when it comes out it pops out quickly and may ends up under the truck.

7) Slide the cable assembly into the hole in the steel crash plate in the dash.

Last edited: