- Thread starter

- #61

Back into it

Made a temporary repair of the tear in the boot using XXXXXX. This photo is looking straight at where the tear was (and the boot is shiny because it has been sprayed with Silicone Spray). By the way, it looks better than it is and I still intend to replace it:

Throughout the booster I have used Silicone Grease but I chose to use Rubber Grease for the end of the mastercylinder (simply because I've always used this grease near brake seals):

Oh yes. A psychiatrist would say I suffer from OCD (Obsessive Compulsive Disorder) and my neighbours think I'm an "eccentric perfectionist" And as reinforcing evidence for these "diagnosii" - I have even painted that little clip before refitting it:

Made a temporary repair of the tear in the boot using XXXXXX. This photo is looking straight at where the tear was (and the boot is shiny because it has been sprayed with Silicone Spray). By the way, it looks better than it is and I still intend to replace it:

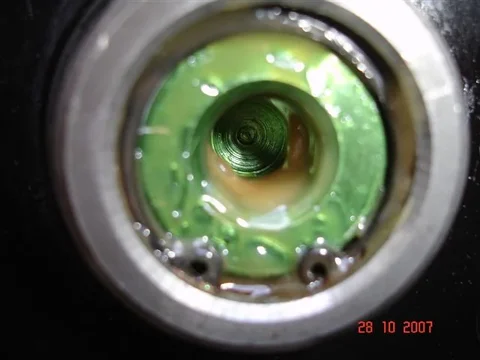

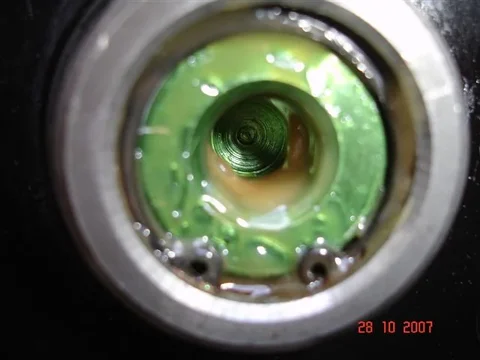

Throughout the booster I have used Silicone Grease but I chose to use Rubber Grease for the end of the mastercylinder (simply because I've always used this grease near brake seals):

Oh yes. A psychiatrist would say I suffer from OCD (Obsessive Compulsive Disorder) and my neighbours think I'm an "eccentric perfectionist" And as reinforcing evidence for these "diagnosii" - I have even painted that little clip before refitting it:

Last edited:

's Nissan car as well as on the BJ40.

's Nissan car as well as on the BJ40.