DanS HJ-45

SILVER Star

Well, as you're finding out, none of this stuff is plug and play. Nothing that can't be done with a little fabbing. Looks like you're on the right track, perseverance is the key. That, and learning body work

Yeah. Wasn't expecting "plug and play," but they forced me to put a seam in places I'm not so sure I'd otherwise place it....

Either way, it's coming along VERY nicely. Definitely better than patching it with sheet and forming it. For bits that big, it's really nice to have them at least "close" to the right side and shape before I have to start working it.

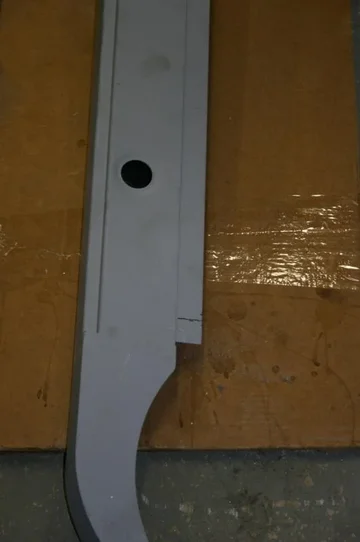

So, I wanted to keep the seam for the panels well clear of the flange along the top of the tub, but I also preferred to use the whole new gas filler cutout, and put the door hinge into a single piece of metal, so the ends of the quarter panel will be higher than the rest of the seam.

And, with a few swipes of the plasma cutter...

), but also because on the inside you'd just see the straight line of the lap joint. Still not convinced that I want to flange the joint (mostly because there are parts I cannot flange, and how to transition smoothly between the butt and lap joints), or that I have the equipment (my flanging tool might not be deep enough to flange two 16GA pieces to end up flush).

), but also because on the inside you'd just see the straight line of the lap joint. Still not convinced that I want to flange the joint (mostly because there are parts I cannot flange, and how to transition smoothly between the butt and lap joints), or that I have the equipment (my flanging tool might not be deep enough to flange two 16GA pieces to end up flush).