- Thread starter

- #461

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Big Red Toy (1 Viewer)

- Thread starter The Phoenician

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #462

Not much to report here. I've been keeping an eye on my MPGs and I'm consistently getting 17 MPG. That's highway and in town diving combined. That also includes two half days of wheeling. I actually think it does worse on the highway since my rpm is around 2000 when cruising. I'm going to be picking up the 3rd members this coming week, but I'm still having my doubts about regearing. The way it drives now, when I shift gears let's say from 3rd to 4th, I have to revv the engine while the clutch is pushed to keep it from dropping the rpms too low. My main reason for regearing is to lower overall EGT, but now I can get it to 900ish to 1000 on the highway. I think regearing would lower the overall cruising highway EGT, but might increase it while I'm accelerating, what do you guys think?

Also here's a picture just to keep you guys interested.

Also here's a picture just to keep you guys interested.

- Thread starter

- #463

wow thats heavy! i want to get mine weighed.

- Thread starter

- #465

The steel wheels, sliders and bumpers really added to the weight

A little different animal with the auto but for me the 4.1 diff ratio and 37s is the best compromise for all round use. I cruise 70 at about 2000 rpm and it feels good there. EGTs are around 900F (down a little since I took a little fuel out of it) at that speed. I average 19 mpg with the way I drive but have gotten anywhere from 16-22 mpg.

With running a manual you have an extra gear to play with and a deep first gear so running 3.7s might be a better set up for you. Kind of depends on your style of driving and what you use your rig most for. If offroad is more important keep the lower gears and live with the compromise. If on road is more important go with the 3.7s and again live with the compromise.

I noticed a mild mileage gain when I changed from those heavy steel wheels to aluminum's.

With running a manual you have an extra gear to play with and a deep first gear so running 3.7s might be a better set up for you. Kind of depends on your style of driving and what you use your rig most for. If offroad is more important keep the lower gears and live with the compromise. If on road is more important go with the 3.7s and again live with the compromise.

I noticed a mild mileage gain when I changed from those heavy steel wheels to aluminum's.

- Thread starter

- #467

A little different animal with the auto but for me the 4.1 diff ratio and 37s is the best compromise for all round use. I cruise 70 at about 2000 rpm and it feels good there. EGTs are around 900F (down a little since I took a little fuel out of it) at that speed. I average 19 mpg with the way I drive but have gotten anywhere from 16-22 mpg.

With running a manual you have an extra gear to play with and a deep first gear so running 3.7s might be a better set up for you. Kind of depends on your style of driving and what you use your rig most for. If offroad is more important keep the lower gears and live with the compromise. If on road is more important go with the 3.7s and again live with the compromise.

I noticed a mild mileage gain when I changed from those heavy steel wheels to aluminum's.

Boots,

Thanks for the input. I live at the edge of the hill country in Texas, but I mostly drive on the flat highway for long distances. I've managed to change my style of driving to where my EGTs are between 900 and 1000. Ambient temperature plays a big role here. I occasionally I push it to 1100-1200 when it needs it. I'm still on the fence about what gears to use, but I will most likely go to 3.7s and try them out. I mostly want to use my rig for going camping in far away areas. I occasionally go crawling with the guys in the local club, but that's too few and far in between. I'm still learning how the engine likes and what I need to pay attention to and what is normal for it. For the longest time i was worried about an oil drip coming out of a rubber hose only to find out that blow by is normal on a Cummins. Will keep everyone posted on results if I go through with it.

- Thread starter

- #468

I had a check engine light come on in my VW. Code says cylinder 4 is misfiring. The check engine light comes on and off during the week and started right after the state inspection happened, like right after, like the minute I pulled out of the driveway from the shop and it turns out they broke my battery cover . I don't believe in coincidences much, but long story short I couldn't drive it from Austin to Ft Worth today. That left me with two other options, take my bike or take Big Red. Had too much stuff to carry and there was a chance of rain according to the forecast, so that left me with Big Red.

. I don't believe in coincidences much, but long story short I couldn't drive it from Austin to Ft Worth today. That left me with two other options, take my bike or take Big Red. Had too much stuff to carry and there was a chance of rain according to the forecast, so that left me with Big Red.

So I had to take fix the cigarette lighter which had a loose wire in order to charge my phone and to use the GPS. Took the dash apart with the help of a friend and reconnected it. I also pressure tested the cooling system and there seems to be a small leak somewhere, but I didn't have time to address it.

Then I set sail north. I must admit I was pleasantly surprised with the drive. This is the farthest I have taken it since the diesel swap. The EGTs were at 1000 then dropped as the sun sank to about 800 - 900 ( at one point it hit 750 on a long straight). So I probably need to invest in a much larger inter cooler. I was staying at a steady high 60s or 70 and the best part is it gave me 21.8 MPG That's with the 4.1 gears. I'm wondering what 3.7s would have netted me on this trip. The 3fe was giving me about 9mpg if I drove conservatively, so overall I'm really happy with this conversion.

That's with the 4.1 gears. I'm wondering what 3.7s would have netted me on this trip. The 3fe was giving me about 9mpg if I drove conservatively, so overall I'm really happy with this conversion.

So I had to take fix the cigarette lighter which had a loose wire in order to charge my phone and to use the GPS. Took the dash apart with the help of a friend and reconnected it. I also pressure tested the cooling system and there seems to be a small leak somewhere, but I didn't have time to address it.

Then I set sail north. I must admit I was pleasantly surprised with the drive. This is the farthest I have taken it since the diesel swap. The EGTs were at 1000 then dropped as the sun sank to about 800 - 900 ( at one point it hit 750 on a long straight). So I probably need to invest in a much larger inter cooler. I was staying at a steady high 60s or 70 and the best part is it gave me 21.8 MPG

That's with the 4.1 gears. I'm wondering what 3.7s would have netted me on this trip. The 3fe was giving me about 9mpg if I drove conservatively, so overall I'm really happy with this conversion.

That's with the 4.1 gears. I'm wondering what 3.7s would have netted me on this trip. The 3fe was giving me about 9mpg if I drove conservatively, so overall I'm really happy with this conversion.- Thread starter

- #469

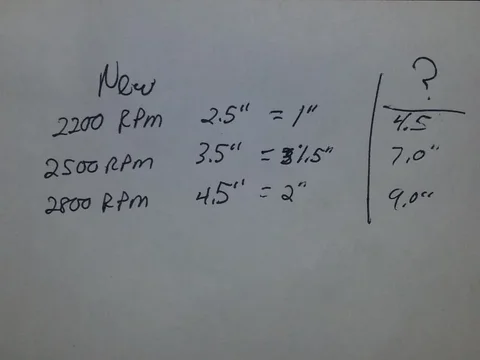

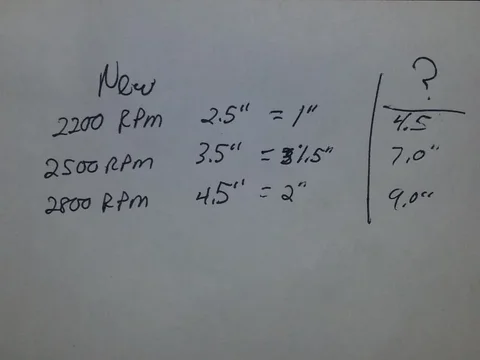

this post is more for the 4bt crowd, it shows how to gauge the health of the engine by measuring the blow by it produces. It's easy to do and gives peace of mind. first you need a 6 ft. clear tube that's 3/8 in. wide on the inner diameter. Hook up a T valve with a cork in it and bore that cork to 15/64 in. Next fill it with water and hang it on your bumper in an even U shape. The take another tube and hook it up to your blow by tube and to the T valve. Make sure to mark the water point before turning it on

The mark the tube at idle, at 2200, 2500 and 2800 rpms. My 4bt doesn't go higher than 2600 so that's where I measured it to. Take a tape measure and measure the drop in water then multiply that by 2, that's the total water it moved. write down your results and compare them to a spec sheet.

My results are in the middle column, the left one shows the maximum level a good engine should displace water, and the right column shows what a bad engine would look like.

You can see my engine move the water 1in. 1.5 inches and 2 inches. essentially still very healthy and newish.

I wrote this up in a hurry, let me know if anything is unclear.

The mark the tube at idle, at 2200, 2500 and 2800 rpms. My 4bt doesn't go higher than 2600 so that's where I measured it to. Take a tape measure and measure the drop in water then multiply that by 2, that's the total water it moved. write down your results and compare them to a spec sheet.

My results are in the middle column, the left one shows the maximum level a good engine should displace water, and the right column shows what a bad engine would look like.

You can see my engine move the water 1in. 1.5 inches and 2 inches. essentially still very healthy and newish.

I wrote this up in a hurry, let me know if anything is unclear.

Nice simple manometer. Still have the setup?

- Thread starter

- #471

Nice simple manometer. Still have the setup?

I left it at school, remind me, I'll see if it's still there.

That is pretty neat man!! Where'd you get the spec sheets, for maximum water movement?

- Thread starter

- #473

Forgot to add the idle picture

This shows how much it dropped from when the engine is off to when it's at idle.

I got the specs from my automotive class. The teacher recently tested his cummins. We just had to look up the 4bt specs, otherwise it's an identical test.

This link should have the correct numbers.

http://www.4btswaps.com/forum/archive/index.php/t-9298.html

This shows how much it dropped from when the engine is off to when it's at idle.

I got the specs from my automotive class. The teacher recently tested his cummins. We just had to look up the 4bt specs, otherwise it's an identical test.

This link should have the correct numbers.

http://www.4btswaps.com/forum/archive/index.php/t-9298.html

- Thread starter

- #474

I spent yesterday installing a new set of horns for the truck before heading out in the pouring rain to pick up my son. I normally would have taken my VW, but it had been giving me a cyclinder 4 misfire reading, so I had no choice but to drive Big Red.

The old stock horn wasn't cutting it over the sound of the engine anymore. I replaced them only to find another issue. The new horn honks intermittently. I check all the wires and the wiring was done right, so I think it's the little pin in the steering column. Will pass by the dealership on monday to grab a new one

Here's the old stock ones.

right side

left side

After Installing them I drove in the rain to pick up my son some 45 miles away. I forgot to turn the snorkel around and halfway there my driver side windshield whipper stopped working. Had to make the rest of the trip leaning towards the passenger side. It was a horrible drive because of bad visibility and hydroplaning on some parts of it. When I got home I decided to get the VW back to road worthiness ASAP.

Here was cylinder 4s problem.

I replaced all the coils and the spark plugs and it's as good as new again.

The old stock horn wasn't cutting it over the sound of the engine anymore. I replaced them only to find another issue. The new horn honks intermittently. I check all the wires and the wiring was done right, so I think it's the little pin in the steering column. Will pass by the dealership on monday to grab a new one

Here's the old stock ones.

right side

left side

After Installing them I drove in the rain to pick up my son some 45 miles away. I forgot to turn the snorkel around and halfway there my driver side windshield whipper stopped working. Had to make the rest of the trip leaning towards the passenger side. It was a horrible drive because of bad visibility and hydroplaning on some parts of it. When I got home I decided to get the VW back to road worthiness ASAP.

Here was cylinder 4s problem.

I replaced all the coils and the spark plugs and it's as good as new again.

- Thread starter

- #475

This morning I was so paranoid about the air box being full of water from yesterday's rain that I opened it up and pulled the filter out. To my surprise the air box only had a tiny film of water at the very bottom after driving it 45 miles each way in the heavy rain. I cleaned it out and dried it. The filter itself was bone dry. I decided to clean it since it was already out.

Cleaned it from all the dust and flying insects that I trapped in there. Came out to almost as good as new.

Before cleaning it, forgot to take an after picture.

After reinstalling it and sealing it with a small layer on silicone, I decided to figure out what was wrong with the driver side windshield whipper. It turns out to just be a loose nut that needed tightening. Whipper works now, hopefully it would never go out in a storm again.

Cleaned it from all the dust and flying insects that I trapped in there. Came out to almost as good as new.

Before cleaning it, forgot to take an after picture.

After reinstalling it and sealing it with a small layer on silicone, I decided to figure out what was wrong with the driver side windshield whipper. It turns out to just be a loose nut that needed tightening. Whipper works now, hopefully it would never go out in a storm again.

- Thread starter

- #476

I guess it's time for an update. I've been busy with life and the other car that I've not done much to Big Red lately. There was one issue plaguing me from the beginning that I needed to address but just got around to it this morning. The pulley on the alternator was too small and the belt didn't have enough wrap around it which caused it to slip under load. So when I turned on the AC or any accessory you can see a significant drop in voltage. My alternator is rated at 150 amps, so nothing should be sucking that much juice. Anyway I went down and got a bigger pulley and drove to the local community college to use their tools and expertise.

Here is Jamie who helped me put the pulley on. He's a retired sailor that worked on jets on air craft carriers. He helped and guided me through the steps.

It as supposed to be an easy swap, but the wrenches couldn't get in there and the nut was rusted on so things had to come off.

Took off the entire bracket since the alternator couldn't slip out the back

The larger pulley stuck out farther so it had to be grinded down.

We got it ground down to near perfect and reassembled it.

Here is Jamie who helped me put the pulley on. He's a retired sailor that worked on jets on air craft carriers. He helped and guided me through the steps.

It as supposed to be an easy swap, but the wrenches couldn't get in there and the nut was rusted on so things had to come off.

Took off the entire bracket since the alternator couldn't slip out the back

The larger pulley stuck out farther so it had to be grinded down.

We got it ground down to near perfect and reassembled it.

- Thread starter

- #477

Here it is reassembled, I know it's hard to tell the difference, but trust me it works great and there's no more voltage drops. The alternator is able to supply the battery and the accessories as needed. My next project is to add another battery in parallel. I don't plan on using a relay solenoid or anything, just hook it up directly to the main battery so that both are used simultaneously. If anyone knows of any drawbacks to the way I'm planning on installing it please let me know. Thanks in advance.

The problem of hooking the battery up in straight parallel is that you can accidentally overcharge a battery and undercharge the other. also, If one battery goes bad, it will draw down the good battery too, best to be able to isolate them. All you really need is a big diode. Boats or RV places will carry the isolator/diode you need.

- Thread starter

- #479

Thanks SmartyPants. I was thinking of that earlier. What amperage rating do you suggest for the isolator switch?

- Thread starter

- #480

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)