I suspect that back in the late seventies there was probably a similar argument/discussion occurring between Toyota electrical engineers.

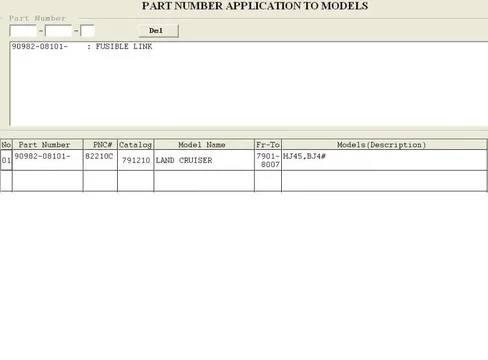

I suspect the engineer who chose to replace the old "full-current ammeter" with the cheaper "shunt-resistor ammeter" wanted a lighter-gauge fusible link to be fitted to ensure his new ammeter performed properly. However I suspect the more-powerful engineer overseeing wiring loom production over-ruled him because he (and I am not sexist .. could be a she

) thought (as I do) that the all-important "reliability aspect" would be compromised by downsizing the link in this way.

Apart from anything else, you never know what a landcruiser owner is going to add in the way of spotlights and other high-current-draw accessories!

I admit that the reliability problem is possibly not as bad as one would think from the way I'm behaving. And I accept that I am probably obsessed with "reliability".

Truth is, while your alternator is running, the voltage being fed to downstream components CANNOT be compromised by any "undersized fusible link" because the alternator "back-feeds" the battery through the fusible link. So while the alternator is running downstream components will actually be getting fed with up to say 14.4V in my case or double that ... 28.8V in the case of your 24V cruiser (from the alternator).

The possible harm (from low downstream voltage) comes when your alternator isn't working which is when

- it is carput/stuffed, or

- your engine isn't running (maybe when you're about to start it), or

- your engine is still revolving but you've just turned your ignition key to "off".

And your fusible link is under maximum stress when

- you have a flat battery and have just started your engine so all the alternator output is going into charging your flat battery (or flat batteries - plural),

- whenever it is compromised by corrosion or broken strands,

- when your engine is off and for some reason you have all your lights on and perhaps have the key in the "motor run" position with the heater on full-bore too etc

- you've upgraded to a more powerful alternator or fitted spotlights or other high-current accessories (exacerbating the above)

- etc

And the effects of corrosion (and of metal-fatigue if the wire has any movenent) will be more likely to lead to failure with lighter-gauge link wire nof course.

So to round this up (and if you're really keen to see your new ammeter become useful), I reckon you should experiment with fitting smaller gauge link wire and perhaps carry a made-up spare "fusible link assembly" (as photographed in this thread) in case it ever fails on you.

(Your spare could perhaps incorporate the normal heavier gauge link wire.)

With good knowledge on what you're doing you'll probably succeed and run for at least a decade with a functioning ammeter and with no associated breakdowns/ill-effects.

If you do ... please post up all about it.