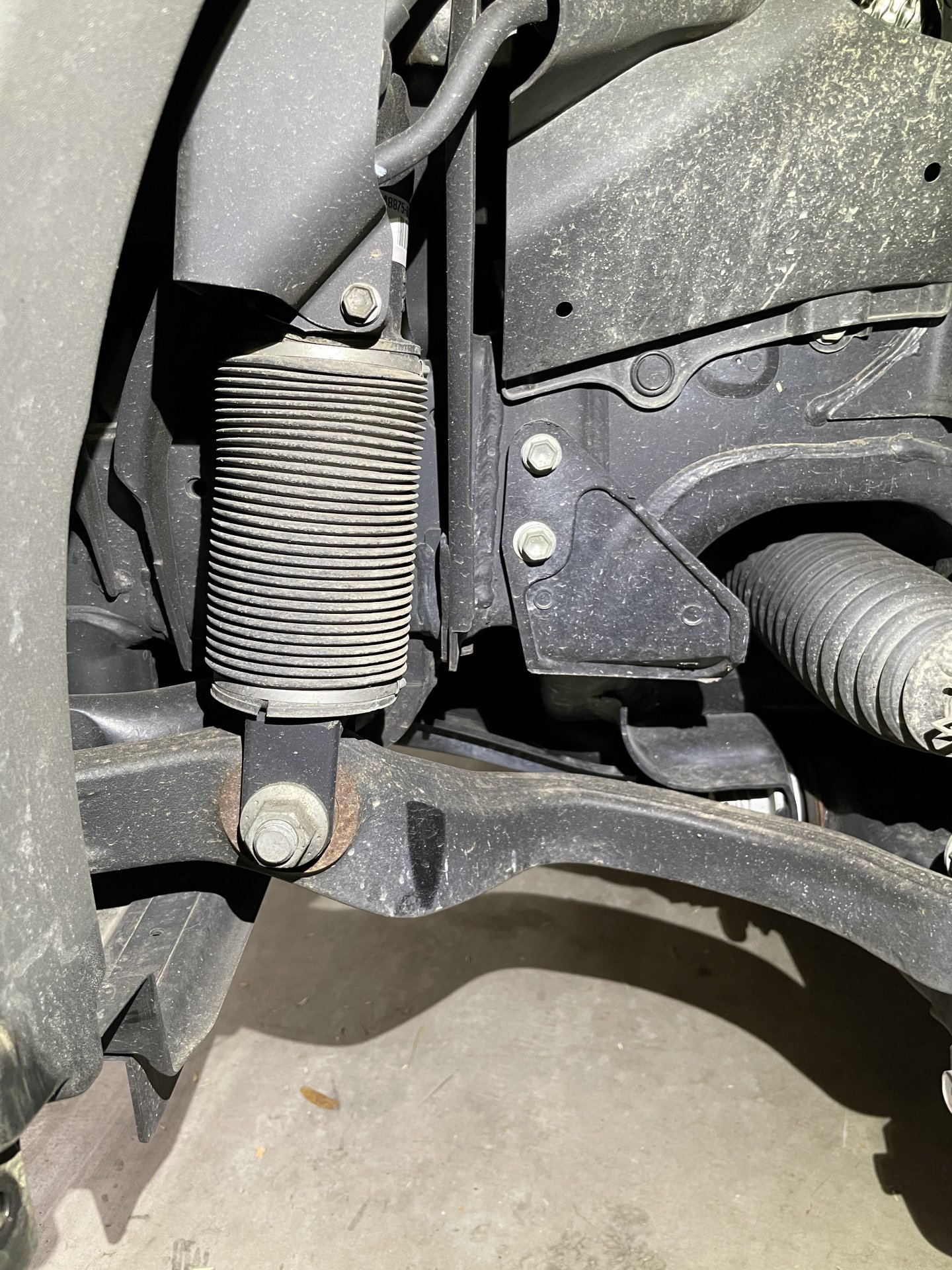

Err. Let me remind/show you about the portal axles.Nothing lifts the diff but larger diameter tires.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

34s vs 35s on the 200

- Thread starter mcgaskins

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Err. Let me remind/show you about the portal axles.

Talk about a mod that requires a seething hate of money and wheelbarrows full of it.

If you’ve got the cash I’ve got t wheelbarrowsTalk about a mod that requires a seething hate of money and wheelbarrows full of it.

With 2” front lift-

285/70r18 Ridge Grapplers on stock 18’s rub KDSS bar in reverse. Too. I have contact for me.

I slightly graze the KDSS with 1.25” spacers. Only at full lock in reverse. I subconsciously drive around it at this point. With the spacers on I had to heat mold the front of the liner and remove the mud flaps. No rub with daily driving. No running during light off roaring either. Hasn’t been tested at full stuff.

285/70r18 Ridge Grapplers on stock 18’s rub KDSS bar in reverse. Too. I have contact for me.

I slightly graze the KDSS with 1.25” spacers. Only at full lock in reverse. I subconsciously drive around it at this point. With the spacers on I had to heat mold the front of the liner and remove the mud flaps. No rub with daily driving. No running during light off roaring either. Hasn’t been tested at full stuff.

With 2” front lift-

285/70r18 Ridge Grapplers on stock 18’s rub KDSS bar in reverse. Too. I have contact for me.

I slightly graze the KDSS with 1.25” spacers. Only at full lock in reverse. I subconsciously drive around it at this point. With the spacers on I had to heat mold the front of the liner and remove the mud flaps. No rub with daily driving. No running during light off roaring either. Hasn’t been tested at full stuff.

Why did you go with the 1.25" spacers, and are they spydertrak vs the 0.75" bora?

I finally got out there tonight to ad

I finally got out there tonight and pulled the mud flaps off. There was some serious rubbing going on. Also rubbing on the front liner and slightly on the KDSS. See pics. After removing the flaps on the front, there is still some slight rubbing on the front of the liner at full reverse. A little heat gun action will probably help, but lift is coming soon, so I may wait to do any adjusting.No, I went straight to the spacers. I’ll try to take some pictures of where they are touching before I remove anything.

TLC2013

SILVER Star

That doesnt look like much rubbing at all. What part of the tire is causing that rub mark? Are you seeing any rubbing on the passenger side kdss?I finally got out there tonight to ad

I finally got out there tonight and pulled the mud flaps off. There was some serious rubbing going on. Also rubbing on the front liner and slightly on the KDSS. See pics. After removing the flaps on the front, there is still some slight rubbing on the front of the liner at full reverse. A little heat gun action will probably help, but lift is coming soon, so I may wait to do any adjusting.

View attachment 2573806View attachment 2573805

View attachment 2573808

I wonder if a smaller spacer like 0.75" would makes things better or worse?

There is a write up to cut a 1/2 moon and fit the front mud flaps back on.

The tire fit right inside that bend in the KDSS so I think the 0.75" spacers should work. Will find out when they arrive in a few weeks.

It was only the front left that had KDSS contact.

The tire fit right inside that bend in the KDSS so I think the 0.75" spacers should work. Will find out when they arrive in a few weeks.

It was only the front left that had KDSS contact.

Spacers will probably make it worse. they make the arc the outer edge of the wheel travels wider, plus the rear mudflap area is already weirdly sculpted (it's not a smooth arc) so you'll rub that more.That doesnt look like much rubbing at all. What part of the tire is causing that rub mark? Are you seeing any rubbing on the passenger side kdss?

I wonder if a smaller spacer like 0.75" would makes things better or worse?

mud flap removal and a heat gun in the rear. You might be able to heat gun the front, otherwise grab a box cutter or some strong scissors and just cut the bottom ~6" off the liner... that's what I did until I eventually got a metal front bumper.

The KDSS rub is typical. You might rub the passengers side sway bar the same way at full left lock too. Can't really do much about those unless you do the KDSS relo bracket.

TLC2013

SILVER Star

I keep hoping someone will find that Unicorn offset/spacer wheel combo that will make the Lt285/70r18 fit without hitting the KDSS. No interest in the relocation bracket.Spacers will probably make it worse. they make the arc the outer edge of the wheel travels wider, plus the rear mudflap area is already weirdly sculpted (it's not a smooth arc) so you'll rub that more.

mud flap removal and a heat gun in the rear. You might be able to heat gun the front, otherwise grab a box cutter or some strong scissors and just cut the bottom ~6" off the liner... that's what I did until I eventually got a metal front bumper.

The KDSS rub is typical. You might rub the passengers side sway bar the same way at full left lock too. Can't really do much about those unless you do the KDSS relo bracket.

My Kenda Klevers measure 33.43x11.22 (LT275/70r18) and I nearly rub the driver side KDSS, looks like of piece of paper would barely fit between the tire and sway bar at full steering wheel lock.

LT285/70r18 is over 1/2” bigger then what I am running so I don’t see how it would work with my 45mm offset evo corse wheels.

-50 offset wheels, maybe? You basically have to push them far enough out that at full lock they don't touch the KDSS arm or cylinder at all. Or you could significantly reduce your caster, pushing your wheels further back in the wheel well - which will avoid the KDSS arm but then you will hit the body mount (plus low caster will make the steering feel loose).I keep hoping someone will find that Unicorn offset/spacer wheel combo that will make the Lt285/70r18 fit without hitting the KDSS. No interest in the relocation bracket.

My Kenda Klevers measure 33.43x11.22 (LT275/70r18) and I nearly rub the driver side KDSS, looks like of piece of paper would barely fit between the tire and sway bar at full steering wheel lock.

LT285/70r18 is over 1/2” bigger then what I am running so I don’t see how it would work with my 45mm offset evo corse wheels.

I have +25 offset wheels and 285/75R17 tires, which are basically the same size as 285/70R18. I rub the KDSS at full lock, which only happens when parking. I don't think +0 offset would be sufficient, you'd have to go even lower, which is a lot of stress on the bearings not to mention the risk of smashing a fender on a big bump

TLC2013

SILVER Star

Good info here, thanks @linuxgod-50 offset wheels, maybe? You basically have to push them far enough out that at full lock they don't touch the KDSS arm or cylinder at all. Or you could significantly reduce your caster, pushing your wheels further back in the wheel well - which will avoid the KDSS arm but then you will hit the body mount (plus low caster will make the steering feel loose).

I have +25 offset wheels and 285/75R17 tires, which are basically the same size as 285/70R18. I rub the KDSS at full lock, which only happens when parking. I don't think +0 offset would be sufficient, you'd have to go even lower, which is a lot of stress on the bearings not to mention the risk of smashing a fender on a big bump

I would like to keep my offset at +25 and higher, sounds like I’ll have to pass on this size for now.

one thing I haven’t messed with too much is alignment. My caster is just above 3 degrees, truck drives well and doesn’t wander so I should probably just leave things alone.... which is easier said then done lol.

Yeah, really just depends on how much rubbing you're OK with. If the answer is zero, then stick with what ya' got. As I said I'm at +25 offset and on 34s and it only rubs at full lock... If it rubs you can feel it but it doesn't stop the vehicle or tear up the tire lugs. If I let off the steering wheel slightly there's no rub, and I've gotten used to doing that. My wife knows to do the same thing. Anything bigger than 285/75R17 or 285/70R18 I wouldn't try without KDSS relo thoughGood info here, thanks @linuxgod

I would like to keep my offset at +25 and higher, sounds like I’ll have to pass on this size for now.

one thing I haven’t messed with too much is alignment. My caster is just above 3 degrees, truck drives well and doesn’t wander so I should probably just leave things alone.... which is easier said then done lol.

Any info or write-up on how to do this? Is it an easy job for someone who never did it before?unless you do the KDSS relo bracket.

Any info or write-up on how to do this? Is it an easy job for someone who never did it before?

KDSS relocation bracket

forum.ih8mud.com

forum.ih8mud.com

The install itself is just a few bolts. The tricky part is that you need to get the sway bar into position.

Downside to doing this is that is puts the sway bar end links at an angle which causes them to wear faster. A couple people have apparently solved this by moving the end links to the *outside* of the LCA cradle.

My biggest pet peeve with relocation I have not found anyone making the brackets out of Steel ?

I would have thought someone would have made a aftermarket redesigned replacement arm for the KDSS .

I have been keeping my eye’s open for a spare 2 arms I may modify to add some relief area where the arm rubs on the tire area .

I would need 2 arms , I have welded steering arms in the past , you just have to know what your doing to weld forged steel .

Basiclly machine and sister backside weld in the area I am going to machine for clearance .

I would have thought someone would have made a aftermarket redesigned replacement arm for the KDSS .

I have been keeping my eye’s open for a spare 2 arms I may modify to add some relief area where the arm rubs on the tire area .

I would need 2 arms , I have welded steering arms in the past , you just have to know what your doing to weld forged steel .

Basiclly machine and sister backside weld in the area I am going to machine for clearance .

My biggest pet peeve with relocation I have not found anyone making the brackets out of Steel ?

I would have thought someone would have made a aftermarket redesigned replacement arm for the KDSS .

I have been keeping my eye’s open for a spare 2 arms I may modify to add some relief area where the arm rubs on the tire area .

I would need 2 arms , I have welded steering arms in the past , you just have to know what your doing to weld forged steel .

Basiclly machine and sister backside weld in the area I am going to machine for clearance .

The KDSS bar itself is a pretty unique in shape and configuration as far as sway bars go. I wouldn't hold my breadth for anything like it in the aftermarket.

If you've got that level of skill, wouldn't it be easier to make the relocation bracket yourself out of steel (surprised they are not?). It's a pretty simple blocks. The end link geometry is solved in my mind with how they are attaching it to the LCA. Perhaps one could reweld the bucket to return it to a dual shear configuration?

No offense but isn’t this way too much complication for an extra 1/2” (285s) which is an effective 1/4” clearance when 275/70-18 fits like a glove with 0 adjustments? (I know there is another 1/2 in width)

most manufacturers make 2 versions of this size (at least GY and Toyo at least) one on the smaller end of the spectrum and another one on the higher end. My Duratracas measure…

33.4”x11” product code 312012142

Link

and they fit with 0 issues. (I have 1” lift up front with Bilstein 6112))

just saying, bolt on and forget it

most manufacturers make 2 versions of this size (at least GY and Toyo at least) one on the smaller end of the spectrum and another one on the higher end. My Duratracas measure…

33.4”x11” product code 312012142

Link

and they fit with 0 issues. (I have 1” lift up front with Bilstein 6112))

just saying, bolt on and forget it

No offense but isn’t this way too much complication for an extra 1/2” (285s) which is an effective 1/4” clearance when 275/70-18 fits like a glove with 0 adjustments? (I know there is another 1/2 in width)

most manufacturers make 2 versions of this size (at least GY and Toyo at least) one on the smaller end of the spectrum and another one on the higher end. My Duratracas measure…

33.4”x11” product code 312012142

Link

and they fit with 0 issues. (I have 1” lift up front with Bilstein 6112))

just saying, bolt on and forget it

Different strokes for different folks.

It's a disease, but as a lifelong tinkerer, the degree of complication is subjective. What's the fun in a easy fitments? I'm all for exploring and pushing boundaries, yet I'd hardly consider myself extreme. The 200-series takes bigger tires with relative ease in my mind. Helps when it's all well documented here.

I thought the Slee brackets were steel?My biggest pet peeve with relocation I have not found anyone making the brackets out of Steel ?

I would have thought someone would have made a aftermarket redesigned replacement arm for the KDSS .

I have been keeping my eye’s open for a spare 2 arms I may modify to add some relief area where the arm rubs on the tire area .

I would need 2 arms , I have welded steering arms in the past , you just have to know what your doing to weld forged steel .

Basiclly machine and sister backside weld in the area I am going to machine for clearance .

Similar threads

- Replies

- 64

- Views

- 6K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)