- Thread starter

- #121

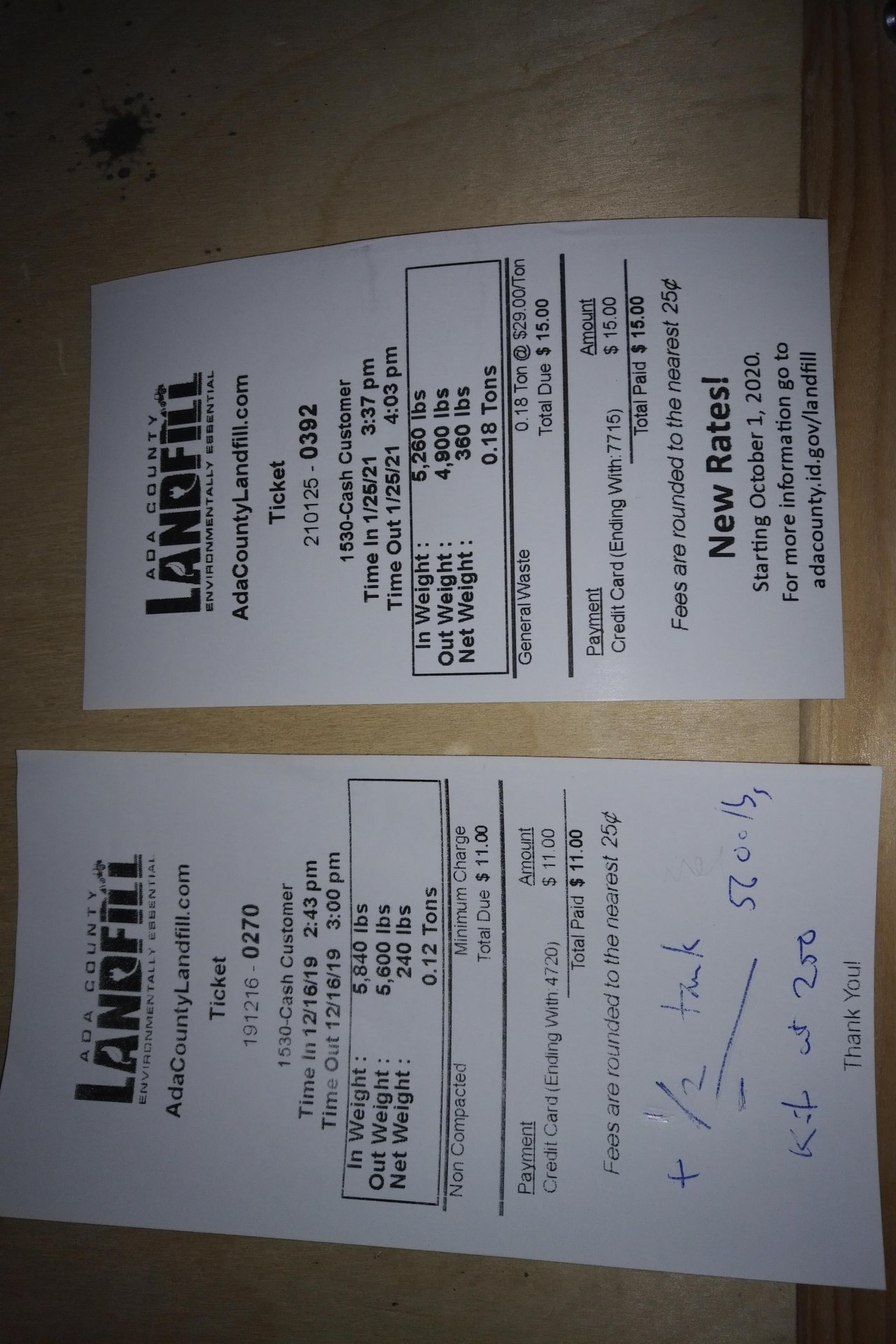

So I took Franky to the dump last night to get rid of the leftovers. I had kept a weight ticket with all the seats in and a 1/2 tank of gas from a year ago. Gas tank was about 6 gallons less yesterday (at a 1/4 tank). The material for the wooden flatbed is about 150 lbs, so based on my numbers over 800 lbs was removed to make a single cab with no bed.

I am estimating about 600 lbs for the steel flatbed, so I should have some pretty good weight distribution/ wiggle room when everything is said and done.

Driving it was fun on the pavement. I could definitely feel the difference in the weight for the get up and go factor. But when I was bouncing around on the dirt roads at the dump, the lack of down travel for the back end was very noticeable. The cab size still feels great, I just feel a little naked when looking out the rear view mirror and seeing nothing behind me!

So long story short on how much time I spent to this point. I started cutting it apart in September and didn't really get into a good roll of working on it until Thanksgiving, xmas and new years holidays. This was because my wife surprised me with a desire to move to the mountains (Cascade, ID) so the kids could go to school full time. Being that it is my hometown, I had no problems with it, but it definitely threw a wrench into my schedule. So this fall, a lot of my weekends were finding a rental, moving stuff north or spending the weekend 75 miles away from my shop with the family. Ended up finding a pretty sweet place though!

I wasn't keeping a log of the time spent on it, but if I had to guess probably 100 hours was spent in the shop at this point. Half of that time was just staring at it trying to figure out what direction to go, so probably 50-70 hours of actual work on it.

I will not have time for the next month or so to do anything with the project as I need to get a house sold, move more stuff, and have a lot going on with work at the moment. But I will put an update in with any milestone that are completed. Flatbed, interior, paint, etc. I want to get those 3 items done before summer so I can start using it for the house build.

My nice to haves will be a front bumper build and a front lift. I am thinking a 1.5" lift in the front will end up working nice after all is complete.

And with that, I will sign off with a picture of my future driveway that I need this 100 series pick-up for. I decided to test the steepness after the first big snow storm with the 80 series. The first stretch is easy, but the second stretch after the switchback ended up taking all the lockers. Oh well, it should be fine if kept plowed (I hope . Maybe I should plan on a mounting location for a snow plow on the front bumper also!

. Maybe I should plan on a mounting location for a snow plow on the front bumper also!

I am estimating about 600 lbs for the steel flatbed, so I should have some pretty good weight distribution/ wiggle room when everything is said and done.

Driving it was fun on the pavement. I could definitely feel the difference in the weight for the get up and go factor. But when I was bouncing around on the dirt roads at the dump, the lack of down travel for the back end was very noticeable. The cab size still feels great, I just feel a little naked when looking out the rear view mirror and seeing nothing behind me!

So long story short on how much time I spent to this point. I started cutting it apart in September and didn't really get into a good roll of working on it until Thanksgiving, xmas and new years holidays. This was because my wife surprised me with a desire to move to the mountains (Cascade, ID) so the kids could go to school full time. Being that it is my hometown, I had no problems with it, but it definitely threw a wrench into my schedule. So this fall, a lot of my weekends were finding a rental, moving stuff north or spending the weekend 75 miles away from my shop with the family. Ended up finding a pretty sweet place though!

I wasn't keeping a log of the time spent on it, but if I had to guess probably 100 hours was spent in the shop at this point. Half of that time was just staring at it trying to figure out what direction to go, so probably 50-70 hours of actual work on it.

I will not have time for the next month or so to do anything with the project as I need to get a house sold, move more stuff, and have a lot going on with work at the moment. But I will put an update in with any milestone that are completed. Flatbed, interior, paint, etc. I want to get those 3 items done before summer so I can start using it for the house build.

My nice to haves will be a front bumper build and a front lift. I am thinking a 1.5" lift in the front will end up working nice after all is complete.

And with that, I will sign off with a picture of my future driveway that I need this 100 series pick-up for. I decided to test the steepness after the first big snow storm with the 80 series. The first stretch is easy, but the second stretch after the switchback ended up taking all the lockers. Oh well, it should be fine if kept plowed (I hope