- Thread starter

- #721

Yup did a smoke test with some local MUD (@CJK @meatloaf5000) turbo owners near me a few weeks ago. Nothing was leaking when we smoked it out for 10 mins. Actually, after that smoke session, I did a trip the next weekend and that's when I got the P0172 CEL code. Coincidence maybe? No idea...My concern is the P0172 may not be responsible for your engine dying, that's a possible vacuum issue. Have you done a smoke test to see where there might be a leak? I know the engine is freshly built before the turbo went in. Also your coolant temp sensor could be another potential issue, if it's the original one.

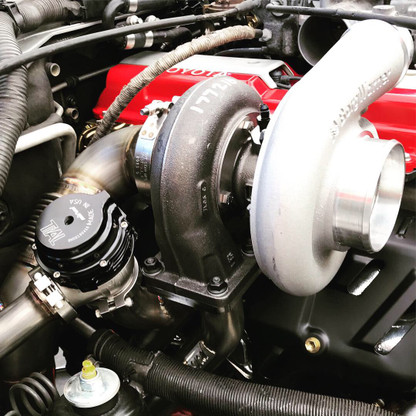

I too have a leak at the J pipe and it's a loud leak under throttle but my engine never stalled. In order to fix the leak, I have to remove the turbo and check the flange for trueness.

P0172: System too rich (Fuel trim): Trouble Areas: fule line pressure; injector leak--blockage; heated O2 sensor malfunction; mass air flow meter; engine coolant temp. sensor

The engine coolant temp sensor was replaced during the rebuild with a brand new OEM one from Souq.

I was thinking the stall at low/stopping speeds was due to the EFI relay being old and getting hot. I did replace that just last week but haven't driven it long enough or HOT enough to rule out the EFI relay fixed the stall.

I'm going to check the Jpipe bolts and every exhaust manifold side and turbo bolt while I'm in there later. I have no idea what this is at this point but will keep troubleshooting till its gone.