Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ARCHIVE Wits' End- If turbo isn't for you, what about going diesel? (1 Viewer)

- Thread starter NLXTACY

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?NO!!!! BAD NLXTACY!!! Engine driven compressor mount for the 1HDt first!!I know I know, turbo first!!

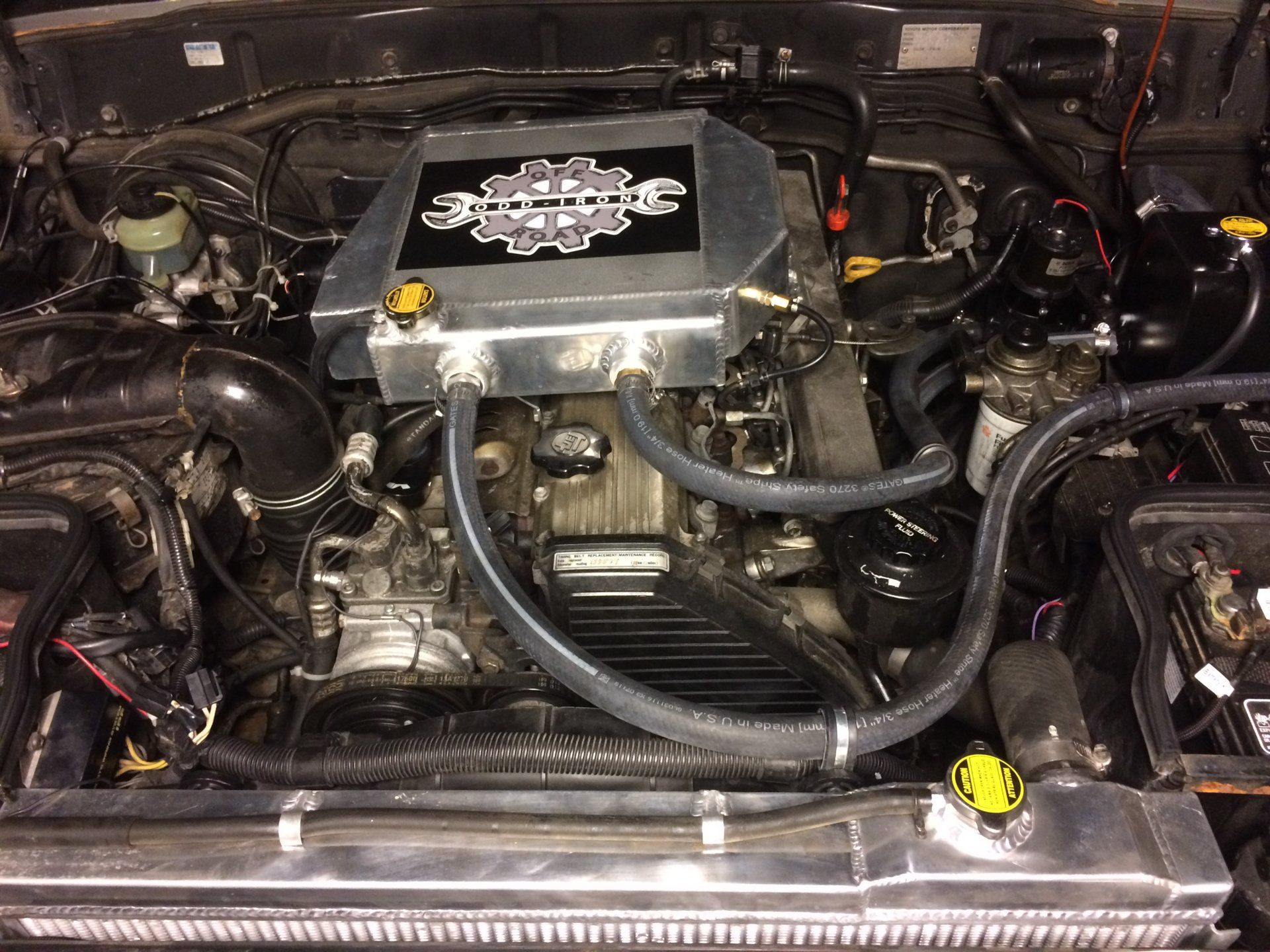

Same engine  Currently looking like this. Note the little empty space next to my AC compressor. There should be a wits end bracket in there holding another compressor. I will even drive this thing to you if you wish.

Currently looking like this. Note the little empty space next to my AC compressor. There should be a wits end bracket in there holding another compressor. I will even drive this thing to you if you wish.

Currently looking like this. Note the little empty space next to my AC compressor. There should be a wits end bracket in there holding another compressor. I will even drive this thing to you if you wish.

Currently looking like this. Note the little empty space next to my AC compressor. There should be a wits end bracket in there holding another compressor. I will even drive this thing to you if you wish.

Easy just use a GM trans and there are already GM auto adapters to Toyota TC's. Marks makes them.

Not opposed to going with an auto that bolts to the cummins to start, doesn't have to stay Toyota. Then just need to go auto trans to Tcase. Suppose I could just use the NWF Black Box to do that though.

Nice project for a good cause though. If I wasn't married I'd look at switching to a manual trans but as is it's not in the cards

NLXTACY

Wits' End

- Thread starter

- #26

Same engineCurrently looking like this. Note the little empty space next to my AC compressor. There should be a wits end bracket in there holding another compressor. I will even drive this thing to you if you wish.

Aren’t you in Georgia?!?!

I have the 77Series here so I’ll go thru and see how it can be done. I have a 22R Mount I’m already working on

Say the word and I will start driving!!! Nice 77Aren’t you in Georgia?!?!

I have the 77Series here so I’ll go thru and see how it can be done. I have a 22R Mount I’m already working on

View attachment 1922814

nukegoat

Should have bought a Jeep

Im no expert but i think thats an input

Dirty Koala

SILVER Star

Another vendor that had these plates had issues with oil transfer from one to another due to those seals are really only directional. Solution was 2 seals one in each direction. FYI. Hope someone that actually had the issue chims in. I don’t use this product and just going from memory.

@cjmoon been talking with quite a few folks about this and no one has brought up this issue. I’m all ears though.

So, oil leaking, if an issue, doesn’t have much to do with the adapter. And isn’t the transfer case a sealed unit? I guess I could kick it over and see

But if you REALLY want/need two seals, the adapter itself doesn’t care.

I will clarify this concern. The early adapters did not include any seal in the adapter plate. @thegogglesdonothing was the unfortunate victim of that design flaw which resulted in trans fluid migrating from the NV4500 into the HF2AV causing the NV4500 to burn up. The input shaft seal on the HF2AV seals fluid on one direction...its designed to keep fluid inside the case...they don't do as well as preventing fluid from getting in. The solution was to make the hole in the adapter plate smaller and the exact same size at the OD of the same seal that is used on the HF2AV input shaft. You then take a 2nd input shaft seal and press it into the adapter plate in the opposite orientation to keep fluid from migrating out of the NF4500. Since that revision, no one else has had any issues.Toyota transfer case is sealed. If there is a leak it’s 100% not because of an adapter.

So total of 2 identical Toyota HF2AV Inputs seals. 1 in the normal position in the transfer case and 1 in the adapter plate but flipped 180 degrees.

Last edited:

Dude, had this project started before the Turbo, I would have passed over the 96 land cruiser and dropped that money into my 93 to prep for diesel.

Sadly, well only figuratively, I’m planning on selling the 93 and pruning the money tree heavily to add a 911 to the fleet.

But I’ll keep an eye on this. Haven’t found the right car yet. I may end up being fickle

Sadly, well only figuratively, I’m planning on selling the 93 and pruning the money tree heavily to add a 911 to the fleet.

But I’ll keep an eye on this. Haven’t found the right car yet. I may end up being fickle

NLXTACY

Wits' End

- Thread starter

- #33

Dude, had this project started before the Turbo, I would have passed over the 96 land cruiser and dropped that money into my 93 to prep for diesel.

Sadly, well only figuratively, I’m planning on selling the 93 and pruning the money tree heavily to add a 911 to the fleet.

But I’ll keep an eye on this. Haven’t found the right car yet. I may end up being fickle

Sooooo, why am I bothering with this diesel stuff? It was for those poor saps with OBD1 who couldn’t take advantage of the turbo.

NLXTACY

Wits' End

- Thread starter

- #34

I will clarify this concern. The early adapters did not include any seal in the adapter plate. @thegogglesdonothing was the unfortunate victim of that design flaw which resulted in trans fluid migrating from the NV4500 into the HF2AV causing the NV4500 to burn up. The input shaft seal on the HF2AV seals fluid on one direction...its designed to keep fluid inside the case...they don't do as well as preventing fluid from getting in. The solution was to make the hole in the adapter plate smaller and the exact same size at the OD of the same seal that is used on the HF2AV input shaft. You then take a 2nd input shaft seal and press it into the adapter plate in the opposite orientation to keep fluid from migrating out of the NF4500. Since that revision, no one else has had any issues.

So total of 2 identical Toyota HF2AV Inputs seals. 1 in the normal position in the transfer case and 1 in the adapter plate but flipped 180 degrees.

Good info. I’ll supply two seals.

mudgudgeon

Resident galah

I’m good at one thing.

It's starting to look like that "one thing" is showing off!

Nice work as usual!

His and hers.Not opposed to going with an auto that bolts to the cummins to start, doesn't have to stay Toyota. Then just need to go auto trans to Tcase. Suppose I could just use the NWF Black Box to do that though.

Nice project for a good cause though. If I wasn't married I'd look at switching to a manual trans but as is it's not in the cards

So what about those of us who want to keep an automatic?

The Cummins uses an adapter (flywheel/flexplate housing) to mate engine to bellhousing. Your only an adapter away to all types of possibilities. Plenty of them out there already for autos. AA has a TC adapter to mate a 4L60 and 4L80 to HF2A. Mainly for the LS swap guys.Different problem looking for a different solution. That requires a bellhousing that I’m not currently equipped to take on.

Jason Andrews

Modaholic

So what about those of us who want to keep an automatic?

Easy just use a GM trans and there are already GM auto adapters to Toyota TC's. Marks makes them.

What automatic are you referring to @Pascoscout ? That is where the problem lies in my experience. The autos that are strong enough to stay together behind a 4bt or 6bt are extremely limited. Most of the best choices, like a 47RH(Dodge), Allison, etc are much longer and quite possibly too big to fit under an 80 all together. Currently the "best" option available for an auto is a 4L80-E which totally defeats the purpose of having a fully mechanical engine. Why add an electronically controlled transmission controller that costs well over $1,000 itself. Most people who do this swap want simplicity.

It would be sweet to get one of the new Aisin's they are putting in the Dodge's in a Cummins 80. I'm sure it is fawkin' monstrous!

Jason Andrews

Modaholic

The Cummins uses an adapter (flywheel/flexplate housing) to mate engine to bellhousing. Your only an adapter away to all types of possibilities. Plenty of them out there already for autos. AA has a TC adapter to mate a 4L60 and 4L80 to HF2A. Mainly for the LS swap guys.

LS swap guys could possibly put down 600 lb/ft of torque but they do it ~5,000rpms. Much different when it's putting down that power at 1600-1800 rpms. Those GM autos won't be very reliable behind even a mild 4bt much less a 6bt. I know this because I run a 700R4 which is the same as a 4L60. I haven't grenade'd mine yet, but I spent may too much building that bag of turds.

JaketheSSnake

SILVER Star

Yeah the 4l60e behind a diesel would be a nightmare. The 4l80e can be built to hold just about anything.LS swap guys could possibly put down 600 lb/ft of torque but they do it ~5,000rpms. Much different when it's putting down that power at 1600-1800 rpms. Those GM autos won't be very reliable behind even a mild 4bt much less a 6bt. I know this because I run a 700R4 which is the same as a 4L60. I haven't grenade'd mine yet, but I spent may too much building that bag of turds.

This thread definitely has my gears turning. I was all set on going diesel but I got screwed out of a good deal on a 6bt and I in no way shape or form wanted to spend $10k on just the swap parts from literally the worst online vendor I've ever heard of. Having Wits end stamped on the parts is definitely making me reconsider things.

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)