Well I have spent the last two weekends replacing the brakes on the FZJ80 to include all new extended flex lines from Beno, rebuilding the calipers, all new hardware and shoes for the park brake and dimples slotted rotors all around. The big time eater is the cleaning of all the parts to a condition to make them ready for rebuild; 23+ years and they showed every year in ring layers like an old tree.

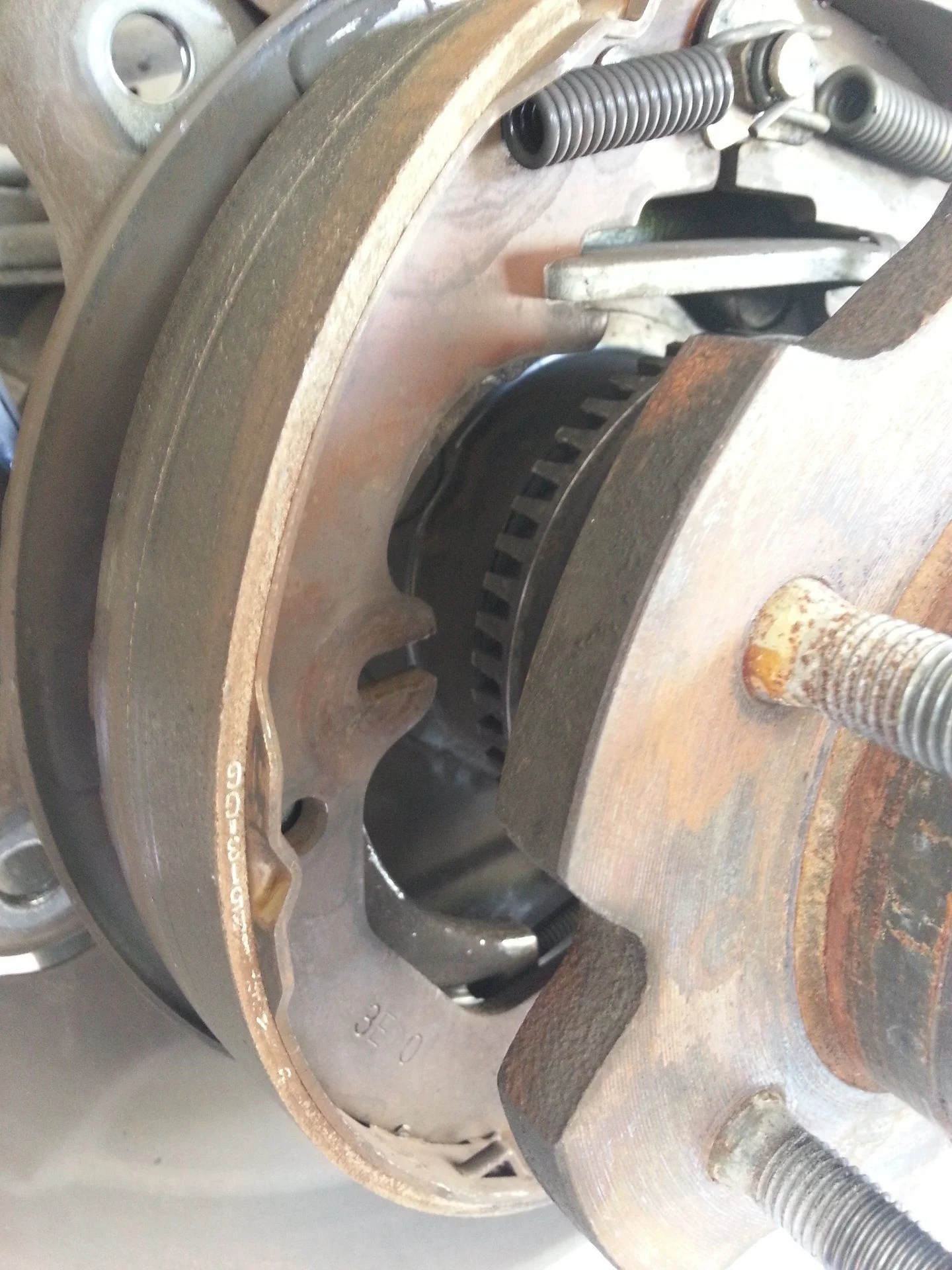

Found that the forward park shoe retainer was missing on the driver side. This explains a few things. Found the spring stuck under the adjuster spring and the seat wedged between the hub and the speed sensor.

As part of this I began to rebuild the front axle as well. Got things apart and cleaned up and hit my first hiccup when the axle seals that came in my Trailgear kit were not the right ones (Way to small) so got the RIGHT ones on order and next is the passenger side axle.

Yes, that is a wheel barrow under the passenger side axle. It made a great drip/crap collector during this.

Looks to me like this got a wee bit hot.

While the drivers side Birf was packed in a moly grease the passenger side was just basic bearing grease and the axle shaft seems to be heat seized in the Birf. An hour of banging using the steel pipe trick (which worked first pop on the long axle) and no sign this short axle is going to budge. Considering a little heat/cool cycling on the axle and give it another go when next I have chance. Other than that I am scratching my head on the next option.

Update:

Couple of heat cycles on the short axle...more time with the pipe slamming, some time with hammer and drift... and it still wants to be part of the birf...any suggestions greatly appreciated.

Found that the forward park shoe retainer was missing on the driver side. This explains a few things. Found the spring stuck under the adjuster spring and the seat wedged between the hub and the speed sensor.

As part of this I began to rebuild the front axle as well. Got things apart and cleaned up and hit my first hiccup when the axle seals that came in my Trailgear kit were not the right ones (Way to small) so got the RIGHT ones on order and next is the passenger side axle.

Trailgear...we have a problem

In the copper corner we have the veteran from the axle wars....in the grey corner, the twins...

Yes, that is a wheel barrow under the passenger side axle. It made a great drip/crap collector during this.

Looks to me like this got a wee bit hot.

While the drivers side Birf was packed in a moly grease the passenger side was just basic bearing grease and the axle shaft seems to be heat seized in the Birf. An hour of banging using the steel pipe trick (which worked first pop on the long axle) and no sign this short axle is going to budge. Considering a little heat/cool cycling on the axle and give it another go when next I have chance. Other than that I am scratching my head on the next option.

Update:

Couple of heat cycles on the short axle...more time with the pipe slamming, some time with hammer and drift... and it still wants to be part of the birf...any suggestions greatly appreciated.

Last edited:

Now I have the engine in a not so great position with the oil pan now actually resting on the cross brace for the frame.

Now I have the engine in a not so great position with the oil pan now actually resting on the cross brace for the frame.