When I chopped off all the extra metal that came on my 1/2 doors I found a problem. Someone had installed a window crank (I bet it was Toyota ), unfortunately most 1/2 doors (mine included) don't even have windows, so that just seemed silly.

), unfortunately most 1/2 doors (mine included) don't even have windows, so that just seemed silly.

What to do with those now useless window cranks? Sell them and install sheet metal covers? The cranks were broken inside, so I wouldn't feel good about selling them, and new replacement window regs are available, and aren't THAT expensive anyway. Then I thought, I'll just remove the crank, patch the hole, paint the panels and bolt them back up, retaining some of the factory details. But THEN I thought: "What a great location (very near the driver and passenger) to have music come out.

The parameters I set were to find speakers that fit the space without visibly enlarging the factory hole. (I did already chop the doors up, I know it shouldn't matter if I adjusted the holes in the doors.) My second goal was to find something with marine application for that "hardtop-is-off but what if it rains?" piece of mind.

These are the units I landed on. Keep in mind, I'm no audiophile (I would never touch an amp or speaker or head unit inappropriately and without first getting consent

) from my admittedly limited research these seemed to "check all the boxes".

) from my admittedly limited research these seemed to "check all the boxes".

First plan was to cut holes in the window crank panel itself and bolt the speakers to the back of the panels, then re-install right back to the factory capture nuts in the doors. However, that would have left the speakers exposed (no grilles) right next to knees, and I'll be taking doors on and off and storing them semi-regularly etc... It seems like a recipe for a punctured speaker. The easiest solution-> Buy some speaker grilles. Well, it SHOULD have been easy. I did not find an appropriately sized speaker grille that also visually matches the vintage looks of the truck. I'm an Art Director so things like that matter to me more than they should. I DO NOT want to install some futuristic looking grille or settle for a boring black mesh oval after all my efforts in the rest of the truck to retain some semblance of original appearance (I'm no purist, but I do think the FJ 40 vintage styling is the damn sexiest thing on four wheels). The only OEM original speaker grille for a 40 that I know of, is basically a piece of sheet metal with some holes drilled through it. It was not designed to be seen. So where does that leave me?

Sometimes you just gotta do stuff yourself. I downloaded a 30-day-trial of a CAD program last weekend, sat down with the window crank panel, the speakers and some calipers and taught myself the software. I've worked in a few 3D modeling programs (more CG animation focused) over the years so it wasn't totally foreign, but I found myself crawling into bed around 2:00 a.m this whole week.

I think I have a CNC guy lined up to mill these out (billet aluminum), however, I still have to follow up with him. I don't think he believed me when I told him I would learn the software and provide him the file.

I present for your consideration, my 1st ever CAD CNC project:

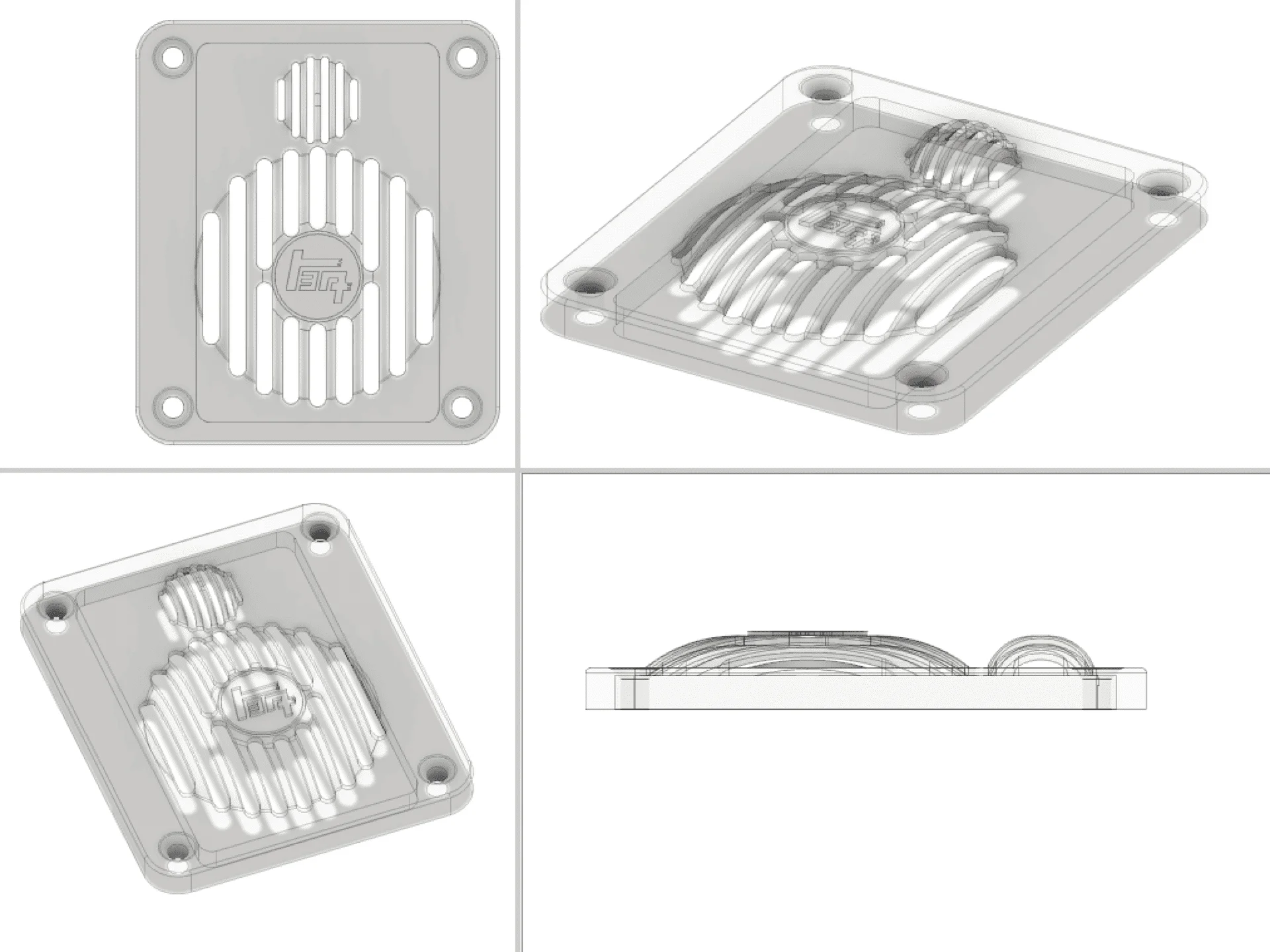

Some wireframe model views:

This view shows the back where speakers nest inside the grille. The outer dimensions of the speaker housings are a little bigger than the door hole but only the magnets end up below the surface of the doors. When these are made I will post pics to explain this more clearly.

The added overall thickness (they are about twice as thick as the OEM panels) is to give them a little bit more space inside the door panels. The backs of the magnets were too close to rubbing inside the door for my tastes (I was worried about them buzzing).

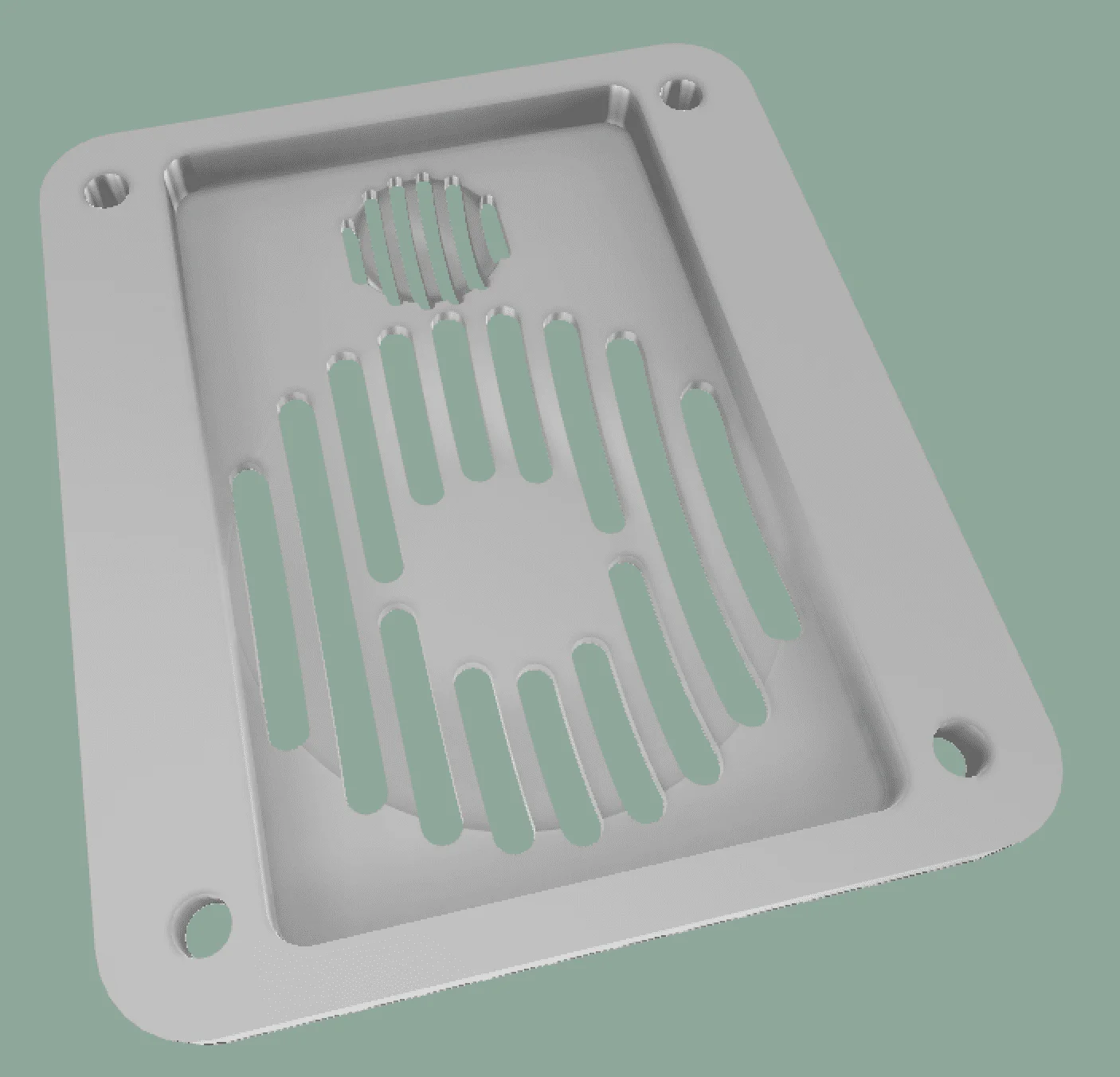

Here is the Final 3D render of what they hopefully should look like when they are milled, I might drizzle some of the nebula green acrylic paint inside the circle around the TEQ for a small added detail (as rendered), but I haven't decided:

They won't be the only speakers in the truck (I want to be able to remove the doors altogether and still have tunes), but they will probably be the prettiest.

What to do with those now useless window cranks? Sell them and install sheet metal covers? The cranks were broken inside, so I wouldn't feel good about selling them, and new replacement window regs are available, and aren't THAT expensive anyway. Then I thought, I'll just remove the crank, patch the hole, paint the panels and bolt them back up, retaining some of the factory details. But THEN I thought: "What a great location (very near the driver and passenger) to have music come out.

The parameters I set were to find speakers that fit the space without visibly enlarging the factory hole. (I did already chop the doors up, I know it shouldn't matter if I adjusted the holes in the doors.) My second goal was to find something with marine application for that "hardtop-is-off but what if it rains?" piece of mind.

These are the units I landed on. Keep in mind, I'm no audiophile (I would never touch an amp or speaker or head unit inappropriately and without first getting consent

) from my admittedly limited research these seemed to "check all the boxes".

) from my admittedly limited research these seemed to "check all the boxes".First plan was to cut holes in the window crank panel itself and bolt the speakers to the back of the panels, then re-install right back to the factory capture nuts in the doors. However, that would have left the speakers exposed (no grilles) right next to knees, and I'll be taking doors on and off and storing them semi-regularly etc... It seems like a recipe for a punctured speaker. The easiest solution-> Buy some speaker grilles. Well, it SHOULD have been easy. I did not find an appropriately sized speaker grille that also visually matches the vintage looks of the truck. I'm an Art Director so things like that matter to me more than they should. I DO NOT want to install some futuristic looking grille or settle for a boring black mesh oval after all my efforts in the rest of the truck to retain some semblance of original appearance (I'm no purist, but I do think the FJ 40 vintage styling is the damn sexiest thing on four wheels). The only OEM original speaker grille for a 40 that I know of, is basically a piece of sheet metal with some holes drilled through it. It was not designed to be seen. So where does that leave me?

Sometimes you just gotta do stuff yourself. I downloaded a 30-day-trial of a CAD program last weekend, sat down with the window crank panel, the speakers and some calipers and taught myself the software. I've worked in a few 3D modeling programs (more CG animation focused) over the years so it wasn't totally foreign, but I found myself crawling into bed around 2:00 a.m this whole week.

I think I have a CNC guy lined up to mill these out (billet aluminum), however, I still have to follow up with him. I don't think he believed me when I told him I would learn the software and provide him the file.

I present for your consideration, my 1st ever CAD CNC project:

Some wireframe model views:

This view shows the back where speakers nest inside the grille. The outer dimensions of the speaker housings are a little bigger than the door hole but only the magnets end up below the surface of the doors. When these are made I will post pics to explain this more clearly.

The added overall thickness (they are about twice as thick as the OEM panels) is to give them a little bit more space inside the door panels. The backs of the magnets were too close to rubbing inside the door for my tastes (I was worried about them buzzing).

Here is the Final 3D render of what they hopefully should look like when they are milled, I might drizzle some of the nebula green acrylic paint inside the circle around the TEQ for a small added detail (as rendered), but I haven't decided:

They won't be the only speakers in the truck (I want to be able to remove the doors altogether and still have tunes), but they will probably be the prettiest.

Last edited: