Tanker120

SILVER Star

Click on "Tool Rolls" below for the SALE thread for Purchase

Tool Rolls <<< click here

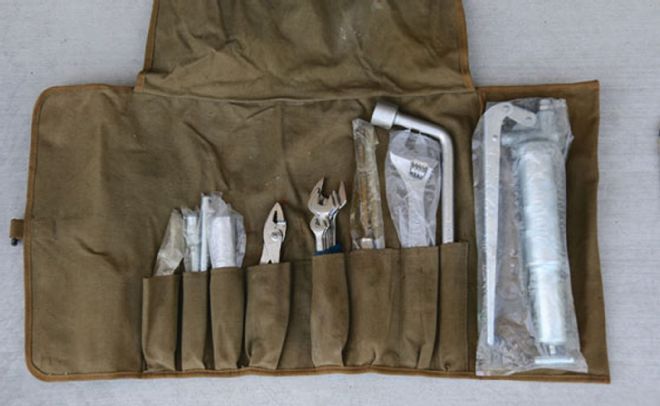

I am starting this thread to hopefully share ideas with anyone wanting to make their own tool rolls, a lot of what I have done was through trial and error (lots of error). I have found lots of information here on MUD, but learned a few other things along the way. I want to share some tricks I have learned and get some thoughts from others.

I got a lot of help form wscbill here on IH8MUD, his documentation and research, is the only reason I was able to get going on this project

I will be updating this over the next few days as I go through the process of making my second batch of rolls.

First post will be about the canvas, not sure if there is a governing agent out there that controls quality or making sure the canvas is what it says it is; I have found lots of variances in thickness and weight among what was supposed to be the same. Enough complaining…..

There are two types of canvas:

“double fill” or “piled yarn”

This canvas uses a Numbered system for Identifying Texture: (#1 - #12) like gauge measurement the higher the number the thinner or finer the texture. For my rolls I use a #10 Canvas or Duck, it seems to be closes to the original, and when compared by weight to the original roll it was very close to the same.

“Single fill”

This canvas uses an ounce weight so a 10 ounces = 10 ounces per square yard which is not the same as #10, which is about 15 oz per square yard of canvas-learned that one the hard way!

Single fill is not as stiff as it only has one yarn of weft were as double fill has two…ok I am not that smart…This info I found is from here:

Cotton Canvas Fabric | Wholesale | Heavyweight | Numbered Duck Cloth

The problem I found is not every manufacture seems to follow the rule or the material is either missed marked or improperly measured, best to get a sample and ordering the material send the sample you want back to the company to make sure color and texture is the same. Another lesson learned here!

True story, ordered a bunch of canvas from a military surplus, he said is was #10, it was a good price so I ordered 10 yards, it was actually 10 ounce and almost like normal material not canvas…..so again get a sample!

OK enough about material texture, now the color. (I will share different Canvas companies that I got the samples from later)

I have found out the Olive Drab (OD) Green has many variances and is anyone’s guess what a true OD Green color is, here is some shades I found, and again back to getting the sample, and once you decide on a color, make sure you send it back and let them know you don’t want any shade darker or lighter, another lessen learned!

Oh and another thing is if you want a treated canvas like the military uses on there tarps and canvas, there is a smell that comes form it, and although it makes the canvas look more authentic (makes canvas look older) I don't believe the original rolls were treated, this treatment makes the canvas heavier and some report that it may effects the coating on the tools. I have chosen not to us this type of canvas. and you will eventually get a nice treatment of oil and grease over the years.....

Main places I used to get samples: (there were others, but these were the main ones)

www.bigduckcanvas.com

www.rockywoods.com

www.ahh.biz/fabric/

Beachwood Canvas Works (treated canvas)

Here are some samples I sent for: all are considered OD Green, I chose the third form the right the two on the right are treated canvas. I went with OD Green because I believe that was close the original color, but again I could be wrong. If you really want to get close you could die the canvas which is not the route I wanted to try.

Thread is the same thing, all considered OD Green:

Next post will be cutting out of the canvas

Tool Rolls <<< click here

I am starting this thread to hopefully share ideas with anyone wanting to make their own tool rolls, a lot of what I have done was through trial and error (lots of error). I have found lots of information here on MUD, but learned a few other things along the way. I want to share some tricks I have learned and get some thoughts from others.

I got a lot of help form wscbill here on IH8MUD, his documentation and research, is the only reason I was able to get going on this project

I will be updating this over the next few days as I go through the process of making my second batch of rolls.

First post will be about the canvas, not sure if there is a governing agent out there that controls quality or making sure the canvas is what it says it is; I have found lots of variances in thickness and weight among what was supposed to be the same. Enough complaining…..

There are two types of canvas:

“double fill” or “piled yarn”

This canvas uses a Numbered system for Identifying Texture: (#1 - #12) like gauge measurement the higher the number the thinner or finer the texture. For my rolls I use a #10 Canvas or Duck, it seems to be closes to the original, and when compared by weight to the original roll it was very close to the same.

“Single fill”

This canvas uses an ounce weight so a 10 ounces = 10 ounces per square yard which is not the same as #10, which is about 15 oz per square yard of canvas-learned that one the hard way!

Single fill is not as stiff as it only has one yarn of weft were as double fill has two…ok I am not that smart…This info I found is from here:

Cotton Canvas Fabric | Wholesale | Heavyweight | Numbered Duck Cloth

The problem I found is not every manufacture seems to follow the rule or the material is either missed marked or improperly measured, best to get a sample and ordering the material send the sample you want back to the company to make sure color and texture is the same. Another lesson learned here!

True story, ordered a bunch of canvas from a military surplus, he said is was #10, it was a good price so I ordered 10 yards, it was actually 10 ounce and almost like normal material not canvas…..so again get a sample!

OK enough about material texture, now the color. (I will share different Canvas companies that I got the samples from later)

I have found out the Olive Drab (OD) Green has many variances and is anyone’s guess what a true OD Green color is, here is some shades I found, and again back to getting the sample, and once you decide on a color, make sure you send it back and let them know you don’t want any shade darker or lighter, another lessen learned!

Oh and another thing is if you want a treated canvas like the military uses on there tarps and canvas, there is a smell that comes form it, and although it makes the canvas look more authentic (makes canvas look older) I don't believe the original rolls were treated, this treatment makes the canvas heavier and some report that it may effects the coating on the tools. I have chosen not to us this type of canvas. and you will eventually get a nice treatment of oil and grease over the years.....

Main places I used to get samples: (there were others, but these were the main ones)

www.bigduckcanvas.com

www.rockywoods.com

www.ahh.biz/fabric/

Beachwood Canvas Works (treated canvas)

Here are some samples I sent for: all are considered OD Green, I chose the third form the right the two on the right are treated canvas. I went with OD Green because I believe that was close the original color, but again I could be wrong. If you really want to get close you could die the canvas which is not the route I wanted to try.

Thread is the same thing, all considered OD Green:

Next post will be cutting out of the canvas

Last edited:

I'm in....

I'm in....