- Thread starter

- #101

Thanks. Got the part number using that funny tool that people call "search"

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Neither the painter nor I were sure which one would look best so he shot them both. Happily, they are both great but the split hood turned out super. I will just wrap the other one up in a safe place in case I drive through a hail storm or something.looks great!!!! lots done...

why did you paint both hoods???

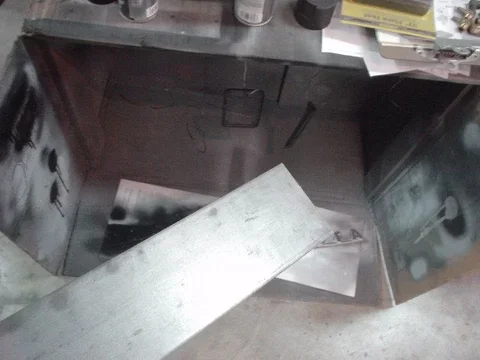

and I got the Paki top in place today.

and I got the Paki top in place today.

Weird too cuz my dad is a furniture and cabinet maker but I did not get that gene. He is extremely handy but is amazed at the progress on the truck.

Weird too cuz my dad is a furniture and cabinet maker but I did not get that gene. He is extremely handy but is amazed at the progress on the truck.

Yeah. I assess the progress at the end of the day and realize how little happened.Nice work dude...you have a boatload more patience than I do.

Yep. I still need to do a little touch up but I am going to clear them. I am pretty pleased. While we were chatting the other day, I know we were both thinking that one should buy new. After all the work that goes into one of these trucks why hang garbage off it but given the way they turned out, I think they will work for me just fine. The white is a kind of a matte texture but really pops against the green.badges look good!!! you going to put clear over the top or just leave them like that?