- Joined

- Nov 22, 2010

- Threads

- 44

- Messages

- 2,144

- Location

- Wilmington, NC

- Website

- www.kindredspiritscsg.com

- Thread starter

- #101

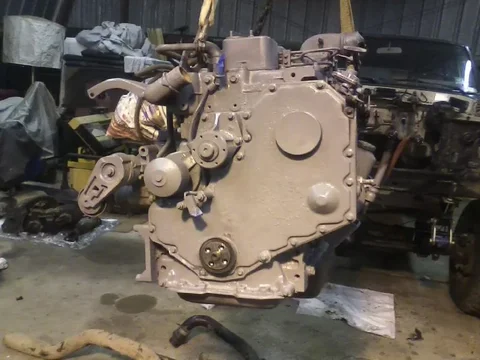

I am going to try and run the mechanical fan if it is at all possible. From looking at the placement of rastaforte's 6bt, it looks like I might be able to just get away with it if I cheat my engine back a bit. and put the radiator for the water to air intercooler in front of my radiator behind the grille. I should have more room up there considering I am not going to be running an AC system.

If not I will run an electric fan. I'll know for sure once I start test fitting the engine.

If not I will run an electric fan. I'll know for sure once I start test fitting the engine.