Hey guys, I hate making a new thread but I couldn't find anything on this.

So I noticed some paint bubbles (Not metal rust bubbles) forming when I first bought the truck when I pressed on them they had a rusty smelling and colored water come out of them (gross).

I then sanded the quarter panel and por15'd and painted. I was patting myself on the back for a week or so then I looked and the paint was bubbling again.... F.

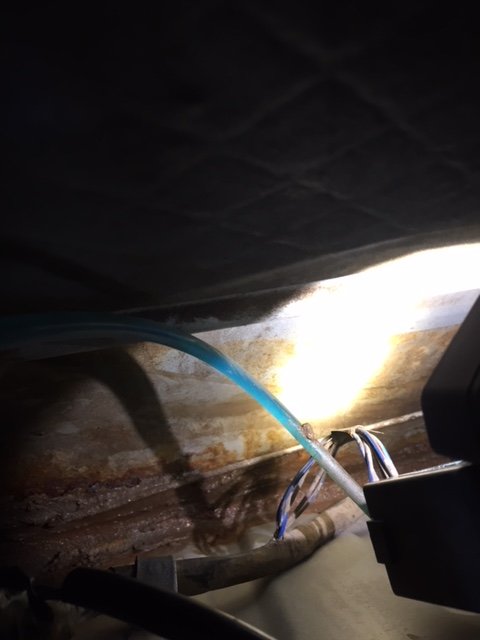

My uncle said that maybe when I started the car because the exhaust pipe (Modified due to the lift kit by a previous owner) was coming out right at the seam of the panel, and maybe condensation was getting up behind it...

SO I went and had the exhaust pipe cut and reconfigured to come out under the bumper like it does stock.

Any ideas of why there may be rust there? or how to mitigate it? When I sanded and painted the metal was clean, and its almost like there is a gap in between the paint on the car and the actual metal of the body...

So I noticed some paint bubbles (Not metal rust bubbles) forming when I first bought the truck when I pressed on them they had a rusty smelling and colored water come out of them (gross).

I then sanded the quarter panel and por15'd and painted. I was patting myself on the back for a week or so then I looked and the paint was bubbling again.... F.

My uncle said that maybe when I started the car because the exhaust pipe (Modified due to the lift kit by a previous owner) was coming out right at the seam of the panel, and maybe condensation was getting up behind it...

SO I went and had the exhaust pipe cut and reconfigured to come out under the bumper like it does stock.

Any ideas of why there may be rust there? or how to mitigate it? When I sanded and painted the metal was clean, and its almost like there is a gap in between the paint on the car and the actual metal of the body...