Not that this will change peoples minds, but here's some information that I would like to post again, and let others make their own decision. The funny thing is everyone keeps quoting how strong the fitting is, but it takes the fitting and tubing together to make a good joint. If you do not follow swagelok's recommendations to the letter, I don't think quoting fitting strength means squat. I know I've posted this before, but it seems that some folks think tubing is tubing, well I would beg to differ.

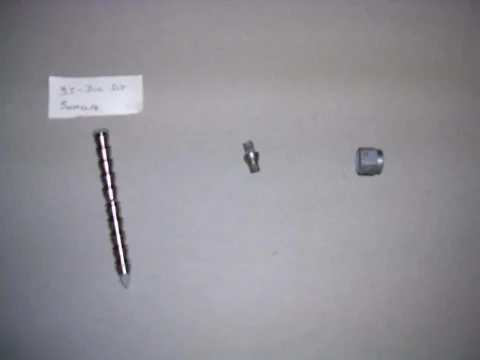

First off, most OEM brake tubing is made from

Bundy tubing, which is actually a thin piece of steel sheet wrapped on itself twice, then brazed. Don't believe me, look here:

Bundy tube - Wikipedia, the free encyclopedia

Next, if you read up on Swagelok's suggested tubing for their fittings, you start to get the idea of all the features needed in the tubing for it to function with their fittings.

http://www.swagelok.com/downloads/we.../MS-13-151.PDF Smooth finish, and appropriate hardness to properly seal against the fittings is required.

My opinion is that I might consider using swagelok fittings on seamless or welded-and-drawn tubing used in a properly designed brake line setup, but I would not bet my life, or anyone else's life on using swagelok fittings on

bundy tubing. My call purely, but if you choose to use them on your rig, I wouldn't want to be in your place if you are the cause of an accident. I know, they've been used before, and might work "most" of the time. It would be nice if someone would call swagelok and find out if they support their fittings on

bundy tubing.

My $0.02

Jeff