SQRRRL

SILVER Star

Looks fantastic!Did not get much done today but a good CLR scrub of the engine bay.

View attachment 2653858

View attachment 2653859

View attachment 2653860

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

Looks fantastic!Did not get much done today but a good CLR scrub of the engine bay.

View attachment 2653858

View attachment 2653859

View attachment 2653860

Looks fantastic!

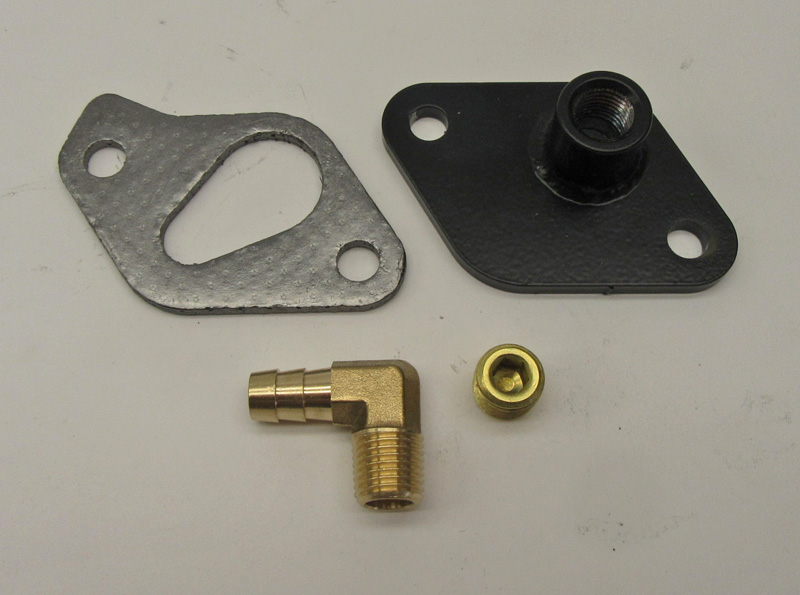

3 notes:Desmog/Sniper has begun.

View attachment 2653080

manafrelv.com

manafrelv.com

When we started this over a year ago I told him it would likely end up being over market value with what all we had planned.You should keep that dude's money, sell my the 60 for $1000 (I'll still need a loan) and, boom...extra grand for Nolen.