Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head Gasket job (total noob) (1 Viewer)

- Thread starter Jorgito

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?I thought these things could be bored over up to 4.7 and run bigger pistons?

I think that an OEM gasket and ARP studs to clamp it tightly and evenly will certainly survive your 15k mile journey in Russia.

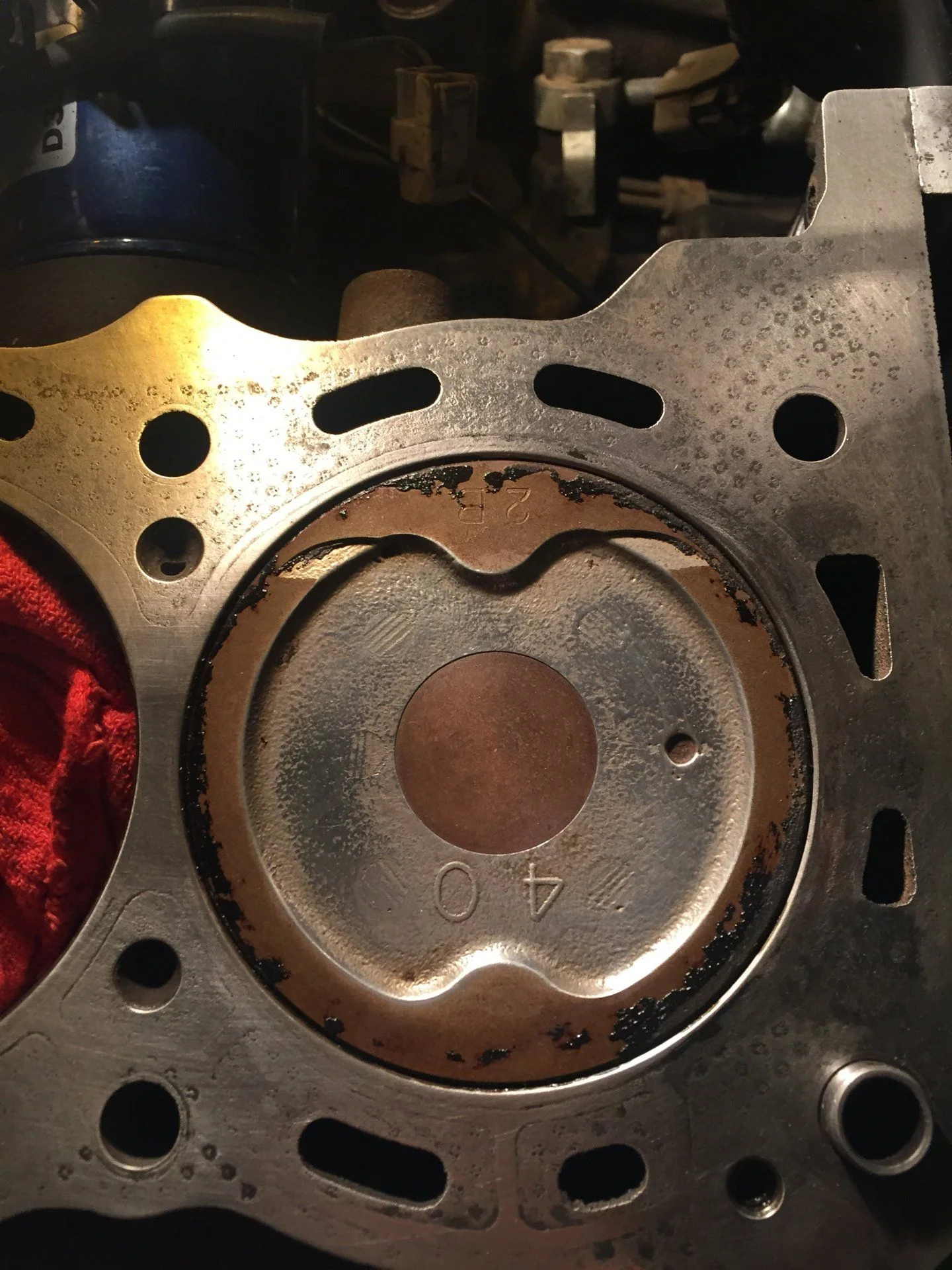

When I talked to the guy at the machine shop about my block the only area he was concerned with was the area that had pitted under the fire ring. The pitting that I see in your pictures is further back on the mating surface and should not matter towards the overall seal of the motor. If you are really worried about it the machine shop can take that out no problem. If you don't want to go to the machine shop you can also get some copper spray a gasket from Permatex, it will help fill in those very minor gaps.

Don't know if you addressed this yet, but this is what worked pretty good for me (post #13169):I have one question regarding the rear heater bypass, what is the best way to get the coolant out of the rear hoses and pipes, it seems to be topped right now. I thought disconnecting some of the rubber hoses near the cat's but I would like to have your opinion on this one.

Thanks,

Jorge

What Did You Do with Your 80 This Weekend?

Hope it helps,

Jen

Ask an expert if a light honing and new rings can take care of that.

- Thread starter

- #149

You are somehow connected with Robbie, as he just wrote me that it would be good idea to do what you mention. Pull the pistons, buy new rings , use a ball hone. The problem is that I went far away from my capability zone of weekend wrencher even with this head gasket project. I simply don't see how could I alone tackle it. It seems the cheapest way forward (around 500 $ for rings, ball hone, rod bearings, o-rings etc).Ask an expert if a light honing and new rings can take care of that.

- Thread starter

- #150

Hi Jen,Don't know if you addressed this yet, but this is what worked pretty good for me (post #13169):

What Did You Do with Your 80 This Weekend?

Hope it helps,

Jen

thanks for the reply, I just ripped the lines from the rear heater below the passanger car. There is a section of rubber hose connecting the rear heater with the small tubes. I got a lot of coolant on me but that's fine.

Jorge

- Thread starter

- #151

I don't know how you guys are cleaning the piston tops but I find it very very frustrating. I followed Robbie's advice (again) and went ahead with cleaning of them with wire brush and carbon cleaner or brake cleaner. I put the piston in TDC and start to clean. This is after two and half hours when I got only one !!! piston little bit cleaned:

Well it seems inevitable to have carbon falling down the piston even when I coat the ring with a lot of oil. I heard guys putting also grease to have nothing falling down. What worries me most is that actually I clean the piston while the piston is wet with brake cleaner as the carbon dissolves much easier and I am afraid that the fluid with carbon will just go down the cylinder. Anybody has some good tips how to proceed ?

Another question I have is regarding the engine wire, I would like to put some heat socket or something to shield the heat from EGR. Question is - shall I unwrap the current wrapping as I am afraid to tear down some cables in process, I would rather just leave the old wrapping and put the new on top of it. I don't see anything wrong with that.

This was a day of up and downs for me

Thanks,

Jorge

Well it seems inevitable to have carbon falling down the piston even when I coat the ring with a lot of oil. I heard guys putting also grease to have nothing falling down. What worries me most is that actually I clean the piston while the piston is wet with brake cleaner as the carbon dissolves much easier and I am afraid that the fluid with carbon will just go down the cylinder. Anybody has some good tips how to proceed ?

Another question I have is regarding the engine wire, I would like to put some heat socket or something to shield the heat from EGR. Question is - shall I unwrap the current wrapping as I am afraid to tear down some cables in process, I would rather just leave the old wrapping and put the new on top of it. I don't see anything wrong with that.

This was a day of up and downs for me

Thanks,

Jorge

Hang in there. You have done a lot so far that should boost your confidence. I would remove the factory heat wrap so I could inspect the harness for heat damage. Mine had three bare wires. If a wire is weak enough to be damaged when you unwrap it then it needed replacing anyway.

That piston top looks pretty good and clean to me. You might try a hard plastic scraper if you want to remove the remaining little bit of carbon.

Did you do a compression test on this engine prior to removing the head? Was it within specs? If not and/or you don't know actual compression numbers, Robbie's advice to hone the cylinders is a good idea.

You can do it because you can take your time and not in a hurry. pulling Pistons would be a pita but it's not rocket science.

That piston top looks pretty good and clean to me. You might try a hard plastic scraper if you want to remove the remaining little bit of carbon.

Did you do a compression test on this engine prior to removing the head? Was it within specs? If not and/or you don't know actual compression numbers, Robbie's advice to hone the cylinders is a good idea.

You can do it because you can take your time and not in a hurry. pulling Pistons would be a pita but it's not rocket science.

Some of the cylinder walls look pretty poor in the photos ....but if you can't feel the pitting maybe the photos are exaggerating the situation. If you do remove the pistons you will have to check the ring grooves. Its a slippery slope now and I would carefully consider your options before you proceed ...among the factors are the general condition of the rest of the vehicle etc. Although if it ran before OK (no knocks,burning oil etc) until the hg finally went ..it should carry on for a while once you replace the hg

Last edited:

BTW for your machine shop ... some very good advice here and why Toyota probably recommends replacement and not machining the head if it is warped:

"...Checking for a warped cylinder head starts with the camshaft bore, NOT the flat portion first. If the cam bore is warped you just wasted your time surfacing the cylinder head. Heat straighten first to align the cam-bore then surface the flat surface. ~ Rico - ASE Master Machinist"

"...Checking for a warped cylinder head starts with the camshaft bore, NOT the flat portion first. If the cam bore is warped you just wasted your time surfacing the cylinder head. Heat straighten first to align the cam-bore then surface the flat surface. ~ Rico - ASE Master Machinist"

- Thread starter

- #157

Hard plastic just doesn't work with this carbon which is really cooked to the pistons. I am now using the razor blade as the wire brush is dissolving from the brake cleaner fluid. Also using the red scotch pad but it is really time consuming.Hang in there. You have done a lot so far that should boost your confidence. I would remove the factory heat wrap so I could inspect the harness for heat damage. Mine had three bare wires. If a wire is weak enough to be damaged when you unwrap it then it needed replacing anyway.

That piston top looks pretty good and clean to me. You might try a hard plastic scraper if you want to remove the remaining little bit of carbon.

Did you do a compression test on this engine prior to removing the head? Was it within specs? If not and/or you don't know actual compression numbers, Robbie's advice to hone the cylinders is a good idea.

You can do it because you can take your time and not in a hurry. pulling Pistons would be a pita but it's not rocket science.

No need to get 100% of the carbon deposits off.

2fpower

SILVER Star

I agree with @Pin_Head and @baldilocks don't worry about cleaning the pistons.

I would NOT bet money on it! Also be cautious with the razor blade on the pistons...the razor blade is fine on the cast iron block but pistons are a softer materialI am sure that the machine shop does check the camshaft bore prior to surfacing the bottom of the head. The head is already in the shop since last Tuesday, still didn't hear anything from them.

Jorge

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)