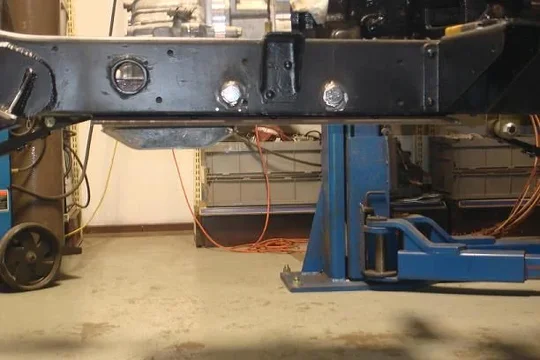

I think rigid will be just fine. That's how the mini's and 4Runners are set up. I'll try to post some pics of the skid plate I'm building so you can have some ideas. Here's a link till then.

https://forum.ih8mud.com/40-55-series-tech/434416-skid-plate-ideas-pictures.html

If the motor mounts aren't rigid then I thought the tranny crossmember shouldn't be rigid either. Think about it, if the motor is allowed to flex its mount but the transmission isn't, then either the transmission or transfercase will be stressed and could crack.

At least that's what I thought...