I can't access the shared Google Drive photos until tonight and there's no hope of a drive by this morning, BUT a glimmer of good news.

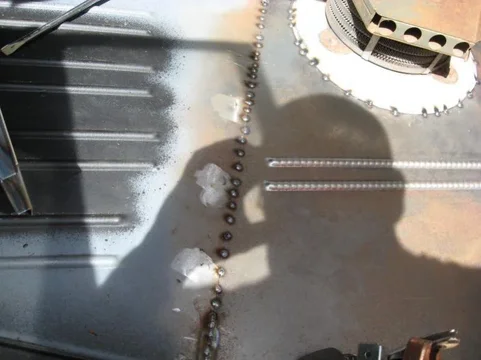

Text me a pic with verbiage of "Here's a little of what we're dealing with." which, of course, had me concerned.

My reply, verbatim (can't take pics of text string without listing his name and wouldn't do that without permission)

"Have seen worse (online) and have seen guys that aren't professionally acclaimed (**) correct with the patch panels, but that's in their leisure time.

What's your professional opinion?"

To which the following reply was given.

"Actually not as bad as I thought..."

[(**) for clarification, my purpose wasn't to slam any Mudder's, but I only know of a few of y'all who are in the resto business.

To me, the floor pans are in relatively good shape in pic, considering they're being cut out anyway, and I've seen a whole lot worse here in the Sty]

Y'all see now why I thought this must've been Mustard. Someone repainted most everything at some point in the past and anywhere I dug that's what I saw.

Get below the bondo and the green comes through and in enough spots that I believe that to be the OE color of the shell and front clip.

forgot to get the link when I did find it

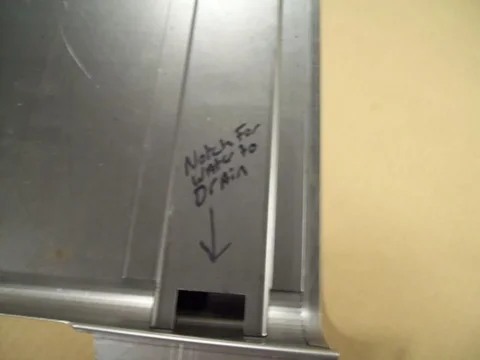

forgot to get the link when I did find it basically, he cut out the rear heater boss from the old floor as it was still good, yours looks to be ok as well- then went about meticulously spot welding the thing into the hole he blew through the new rear drivers side floor patch panel he meticulously reproduced, and then proceeded to meticulously grind the weld smooth for finish and paint...

basically, he cut out the rear heater boss from the old floor as it was still good, yours looks to be ok as well- then went about meticulously spot welding the thing into the hole he blew through the new rear drivers side floor patch panel he meticulously reproduced, and then proceeded to meticulously grind the weld smooth for finish and paint...