HI Guys Ron here I am new to FJs but not restoration work.

I would like to try and help out with what I know.

Amperage = speed ,Clean new cathodes=speed

Paint = slow grease = slow

EVERYTHING to do with this is about SURFACE area and "line of Sight"

Rust must have a direct line of sight to get from cathode to electrode.

This is the same way Chroming works.

No need for the plastic bottle covers

No need for REBAR.

I would not use stainless not all stainless has the same properties.

Depending on part size and wifes tolerance. Cheapo kiddie pools. Plastic drum.

If you live on a farm, dig a pit. Line with blue tarp. Roll the frame and suspension

tires and all, into the pit and derust everything in line of sight.

Draw backs to electrosis it REMOVES the RUST. That corner brace is junk because no structure left.

Had you used a CONVERTER, then the piece would still be useable.

Good is, that it gets down deep to eat rust and this is good but why remove rust when converting it keeps the part stronger?

My 2 cent's worth.

On the cheap- Plastic tarp can be used inside any structure available or as simple as 3 ladders tied in a triangle.

It is way easier to store a tarp and its 100% custom size. No need to do one part at a time,

Do them all at once.

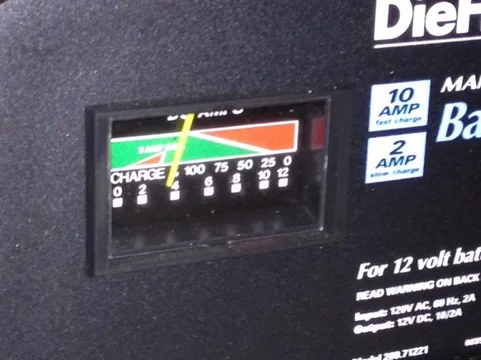

I have seen battery chargers-old microwave power supplies-small welders,etc... as power.

Pultry netting works great as the rust catcher. Cheap.dont feel bad throwing it out. It also lines the BOTTOM.

Remember "line of sight". Bend your rebar into a L shape. Get as much metal as you can in the container to attract the rust.

If the part has grease or paint prep by pressure washer and degreaser. I also use stripper. Wire brush the rust scabs to speed it up.

After the first part is done remove the part put on a empty soup can in place of where the part was and swap the positive with the neg. on your battery charger.

Now all the crud from your "chicken wire-scrap panels-lawn mower blade-refridgerator grates-concrete wire mesh-a simple nut or bolt."

will REVERSE. All the crud will go to the center piece of scrap and clean your wire and "tank". Now the next part will go much faster.

So when recycling your sacrificial metal it will work like it was new.

The gas that comes from this is Hydrogen and VERY flammable. Work in well vented area and do not put a top on it.

Dont smoke near it and turn off the power supply before messing with anything because loose connections can cause a spark.

After you have gotten a FLASH from a spark as you go inside to change your pants, you'll remember the next time.

Sandblasting-it eats good metal to get to the rust pits and never ever gets it down to a mico clean. So even if you use the power derust

use a converter on it OR primer made for clean metal. Phousphoric acid eats rust. This is why COKE and Tinfoil will get rust off a bumper.

COKE is full of phous acid and crinkled tin foil is a scrubby.

Chrome parts with electrolyses will make the water a poison dont do it.

That nasty water and rust ,as long as you prep the part, is GREAT for your lawn.

Your yard loves rust. Makes it greener then a golf course. Loves that IRON. If you have a garden use rusty metal rods to hold up your plants not wood.

Line of sight and a motorcycle tank with rust.

This is a perfect example of REVERSE electrolysis. Use a metal wire to hang a bolt thru the filler neck

Dont let any part of it touch the tank but be suspended inside of the fuel tank.

Reverse the wires and all the rust from inside the tank will be attracted to the bolt.

When done rinse well-heat gun it dry-then use a SWAB[stick with a rag] and swab in white vinegar

and water solution, this will eat the surface flash rust. It takes a while if you move to slow

let it dry and use a tank sealer. The new gasoline will eat anything raw metal. Including your carberatour.

So remember suface rust is one thing and removal of metal makes for a weaker part.

Cheers