Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY 4.3 Re-Gear (2 Viewers)

- Thread starter TeCKis300

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #102

Docking...

Decided on a gasket as Yota intended. It was mentioned in this other thread, but the studs are not studs like earlier generations. They have heads on the inside the diff case.

Decided on a gasket as Yota intended. It was mentioned in this other thread, but the studs are not studs like earlier generations. They have heads on the inside the diff case.

Last edited:

bjowett

Supporting Vendor

Well done!

- Thread starter

- #104

Routed the e-locker wire tied down to the top of the axle at the breather, then up alongside the brake line. All of which is in the shadow of the gas tank.

I have no qualms about it being vulnerable in this position. If I've lost the e-locker due to severing of this line, I've probably got larger problems.

I have no qualms about it being vulnerable in this position. If I've lost the e-locker due to severing of this line, I've probably got larger problems.

Bomar

SILVER Star

You do great write ups....you have made me feel comfortable about getting a 570 soon.

Docking...

Decided on a gasket as Yota intended. It was mentioned in this other thread, but the studs are not studs like earlier generations. They have heads on the inside the diff case.

What do you mean? The studs look just like my 100 series. I cannot find mention of the studs in that other thread, only gasket. Picture?

- Thread starter

- #107

I think someone suggested taking the studs out to clean. I'm not familiar with earlier gen axle housings, but I assume they were saying the studs can be threaded out. The 200-series studs are either pressed in or threaded from the back, as they have heads.

Last edited:

bjowett

Supporting Vendor

They are thread locked into place, but will come out if required.... double nut will do it.

- Thread starter

- #109

Enjoying this off-friday. A little wrenching, a little surfing and posting. It's the end stretch and things are coming together nicely.

New axles bearings done from the fine people at Pro Gear Differentials. I'll dig up the parts list and add here later.

New axles bearings done from the fine people at Pro Gear Differentials. I'll dig up the parts list and add here later.

- Thread starter

- #110

Humpty dumpty is back together again. Even better, she works. And works good!

No unexpected vibration or gear noise. Smooth as butter. Gearing feels better and a bit more snappy down low. I was just really shaking things down rather than going hard. Will let the bearings and stuff break in a bit first. The 5.7L is such a torquey motor that it doesn't really need the gearing unburdened. Just feels like the motor is freer spinning and a bit bored, but shifts do feel more on point. The real test will be when I toss the trailer on.

I did find a stupid steep 45 degree hill. No drama and went up like a champ with center and rear locked. It probably could have done it without the rear locker but with some slip.

There's no feedback to engaging the Harrop locker, no click or noise, which is not as satisfying, but it did lock on cue.

I didn't get a cool picture on the slope as it was too steep to step out of. All I have is a poser shot. I did get to test and am enjoying another mod - independent fogs

No unexpected vibration or gear noise. Smooth as butter. Gearing feels better and a bit more snappy down low. I was just really shaking things down rather than going hard. Will let the bearings and stuff break in a bit first. The 5.7L is such a torquey motor that it doesn't really need the gearing unburdened. Just feels like the motor is freer spinning and a bit bored, but shifts do feel more on point. The real test will be when I toss the trailer on.

I did find a stupid steep 45 degree hill. No drama and went up like a champ with center and rear locked. It probably could have done it without the rear locker but with some slip.

There's no feedback to engaging the Harrop locker, no click or noise, which is not as satisfying, but it did lock on cue.

I didn't get a cool picture on the slope as it was too steep to step out of. All I have is a poser shot. I did get to test and am enjoying another mod - independent fogs

Last edited:

Routed the e-locker wire tied down to the top of the axle at the breather, then up alongside the brake line. All of which is in the shadow of the gas tank.

I have no qualms about it being vulnerable in this position. If I've lost the e-locker due to severing of this line, I've probably got larger problems.

You probably did this but for others here's my Pro Tip (tm): Make sure you have good quality zip ties. I've found some UV-stable ones hold up well to heat, but others will get brittle and crack in a year.

You probably did this but for others here's my Pro Tip (tm): Make sure you have good quality zip ties. I've found some UV-stable ones hold up well to heat, but others will get brittle and crack in a year.

Yes! - The Thomas & Betts brand with UV and the metal tooth. You can usually tell because they have a nice glossy finish. As with all things, you get what you pay for.

bloc

SILVER Star

So @TeCKis300 have you done the math to see exactly where your revs end up at a given speed vs stock? I assume with heavy towing being a big factor for you a goal was to have them end up higher than stock.

I'm looking into this more and worked up some numbers for stock, then my current 285/70/17 and possible 285/75/17 with stock 3.9 and 4.3. I know these numbers don't relate as much to LX tire sizes but I'm betting this thread has the attention of a fair number of cruiser owners too.

stock 200-series RPM @70 1768

stock 3.90

285/70/17 1700

285/75/17 1642

4.30

285/70/17 1873

285/75/17 1811

So assuming I go up in tire size again, I'd be turning less than 50 rpm more than stock at 70mph. Which is about perfect given the increased rolling and wind resistance of the tires and mild lift. Compared to the 70rpm less than stock that I'm turning now with my 285/70s.. and it definitely feels like it could use a bit more RPM at highway speeds between headwinds and hills.

This sounds like a slam dunk.

Now, to take things a step further.. if someone wants to avoid the slightly smaller pinion of your 100-series diff, stock 9.5" 4.30s should be 41201-80493 for a 200. About $900 in the US, $500 international. I do believe that comes as a kit of some kind.. crush sleeve, bolts, maybe shims.. but no bearings. Thanks bjowett for the part number on that.

I'm looking into this more and worked up some numbers for stock, then my current 285/70/17 and possible 285/75/17 with stock 3.9 and 4.3. I know these numbers don't relate as much to LX tire sizes but I'm betting this thread has the attention of a fair number of cruiser owners too.

stock 200-series RPM @70 1768

stock 3.90

285/70/17 1700

285/75/17 1642

4.30

285/70/17 1873

285/75/17 1811

So assuming I go up in tire size again, I'd be turning less than 50 rpm more than stock at 70mph. Which is about perfect given the increased rolling and wind resistance of the tires and mild lift. Compared to the 70rpm less than stock that I'm turning now with my 285/70s.. and it definitely feels like it could use a bit more RPM at highway speeds between headwinds and hills.

This sounds like a slam dunk.

Now, to take things a step further.. if someone wants to avoid the slightly smaller pinion of your 100-series diff, stock 9.5" 4.30s should be 41201-80493 for a 200. About $900 in the US, $500 international. I do believe that comes as a kit of some kind.. crush sleeve, bolts, maybe shims.. but no bearings. Thanks bjowett for the part number on that.

- Thread starter

- #114

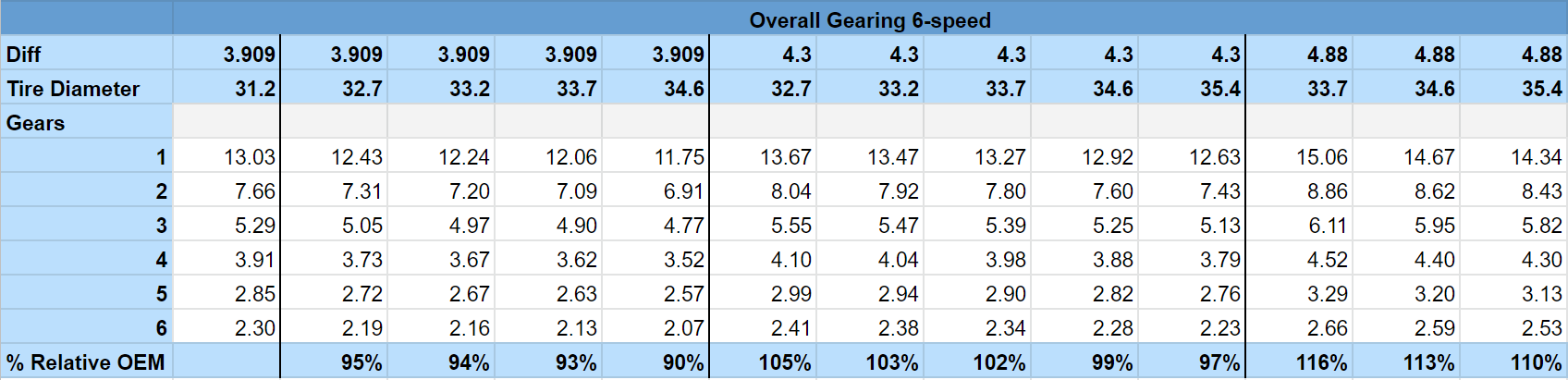

Yes, probably isn't a surprise that I crunched the numbers before such a commitment. Here's some earlier data on that.

This is all as relevant to the LC as it is to the LX. Key dimension from tires is the overall spec diameter which is what affects gearing. 285/70r18 is 32.7". 285/70r18 is 33.7". Since the diff is a modifier to the overall gearing, one easy interpretation is to understand how much percentage gears or tires are going to affect overall gearing. So whatever RPM one is at in whatever gear/speed, just apply the percentage which will then give you the new RPM number. Having run 33.2s

with a rather large gearing disadvantage of 7% - the 5.7 is a brute and puts up with less gearing well, even hauling over 14k lbs worth of rig. From that, my opinion is that 4.3s are perfect for just about every reasonable tire upsize. 4.88s may take this too far unless a rig is built far heavier than stock with far worse aero. Where I want to wind up as a relatively stock weight and stock aero, is 35x12.5 tires at 34.6" tall. With 4.3s, puts my gearing right back at stock.

Data (let me know if I've fat fingered anything)

Thanks for the 4.3 kit part number. That's going to be great for guys that want to regear as good and strong as new. Pinions aren't exactly known to fail, but if one rock crawls enough and really abuses and bangs on the drive shaft, pinion flange, and pinion, that's where they're going to want the full size parts.

This is all as relevant to the LC as it is to the LX. Key dimension from tires is the overall spec diameter which is what affects gearing. 285/70r18 is 32.7". 285/70r18 is 33.7". Since the diff is a modifier to the overall gearing, one easy interpretation is to understand how much percentage gears or tires are going to affect overall gearing. So whatever RPM one is at in whatever gear/speed, just apply the percentage which will then give you the new RPM number. Having run 33.2s

with a rather large gearing disadvantage of 7% - the 5.7 is a brute and puts up with less gearing well, even hauling over 14k lbs worth of rig. From that, my opinion is that 4.3s are perfect for just about every reasonable tire upsize. 4.88s may take this too far unless a rig is built far heavier than stock with far worse aero. Where I want to wind up as a relatively stock weight and stock aero, is 35x12.5 tires at 34.6" tall. With 4.3s, puts my gearing right back at stock.

Data (let me know if I've fat fingered anything)

Thanks for the 4.3 kit part number. That's going to be great for guys that want to regear as good and strong as new. Pinions aren't exactly known to fail, but if one rock crawls enough and really abuses and bangs on the drive shaft, pinion flange, and pinion, that's where they're going to want the full size parts.

Last edited:

No, they don't4.88s may take this too far

. I'm not super heavy (+400 lbs maybe?) and have stock front aero. I do have tall 35s (nearly 35" mounted/weighted measurement). FWIW 4.88s also weren't too much on 275/65r18 (32s). Fully butt dyno approved.

. I'm not super heavy (+400 lbs maybe?) and have stock front aero. I do have tall 35s (nearly 35" mounted/weighted measurement). FWIW 4.88s also weren't too much on 275/65r18 (32s). Fully butt dyno approved.It's like too much ice cream, or too much horsepower, or too many vacation days . . . Getting back to stock is a good target, but no reason to rule out 'better than stock'.

I'm not trying to throw shade on 4.3s. I think there are a lot of reasons to do this mod (economy, OE parts, good fit for medium size tires and loads, proven DIY, approachable ratio change, etc). I think a lot of builds (frankly any rig, even unbuilt) could absolutely benefit from a gear change like this. Sliding down the slope of heavier tires, heavier loads, worse aero is easy to do, and it is done incrementally so that the loss at any one point isn't really noticeable. Until you wake up one day and your rig doesn't perform like you want. 4.3s to the rescue!

- Thread starter

- #116

Great reasons and I can't fault any of that. It's a personal choice in the end of how one wants to bias their vehicle. Your data point having done the 4.88 gears in your setup proves it can work and work well. As you know, I tend to go with more generally conservative approaches.

Just for you @grinchy , I expanded my table above to cover into 33s with 4.88s. Cheers.

Just for you @grinchy , I expanded my table above to cover into 33s with 4.88s. Cheers.

4.30 is probably a good target if you aren't towing, even if you're partially built like my truck, or if you are towing but aren't modified. Maybe a full build that's over 8k would warrant 4.88 to feel sprightly again. Stock gears on 34s with ECT PWR on feels similar to me to stock gears on 31s with ECT PWR off - just a bit sluggish and really requiring some skinny pedal effort to move the rig.

Towing and with mods I'm leaning more and more towards 4.88s. I know it's ~11% more RPMs but the amount of effort currently required to move 14k lbs leads me to believe it'll require a lot less pedal with taller gearing. Consider that a lot of manufacturers offer a tow package which is not just the trailer hitch and wiring but also taller gearing but otherwise the same engine, transmission, and tire sizes. I wish there was a Toyota option for front and rear gears, but beggars can't be choosers.

I just broke 100k this winter so now that I'm officially out of all warranty periods I'm ready to re-gear. I was hoping to do it before the LCDC but I'm kind of cash constrained (to put it mildly) having not sold our other house yet. Next year...

Side question regarding strength: anyone see additional benefits to cryo treatment on the driveline components?

Towing and with mods I'm leaning more and more towards 4.88s. I know it's ~11% more RPMs but the amount of effort currently required to move 14k lbs leads me to believe it'll require a lot less pedal with taller gearing. Consider that a lot of manufacturers offer a tow package which is not just the trailer hitch and wiring but also taller gearing but otherwise the same engine, transmission, and tire sizes. I wish there was a Toyota option for front and rear gears, but beggars can't be choosers.

I just broke 100k this winter so now that I'm officially out of all warranty periods I'm ready to re-gear. I was hoping to do it before the LCDC but I'm kind of cash constrained (to put it mildly) having not sold our other house yet. Next year...

Side question regarding strength: anyone see additional benefits to cryo treatment on the driveline components?

bloc

SILVER Star

One factor for me is availability of 4.33s in OEM flavor, vs any aftermarket option, at least for the front. Toyota gears just wear SO well.. and with a major eye on keeping my rig sleek and low, and fuel economy as good as possible, AND no significant plans for extended towing, 4.88s are just a bit too far. But then that's why we discuss this stuff.

Sleek, low, and 4.30 gears? Meh! Mod, lift, and 4.88s - if it's worth doing, it's worth overdoing!One factor for me is availability of 4.33s in OEM flavor, vs any aftermarket option, at least for the front. Toyota gears just wear SO well.. and with a major eye on keeping my rig sleek and low, and fuel economy as good as possible, AND no significant plans for extended towing, 4.88s are just a bit too far. But then that's why we discuss this stuff.

bloc

SILVER Star

I get your point (even as a joke), but counter with this example of me getting in over my head. Almost lost one of my hands in the process. Wouldn't have happened if I didn't have lockers.Sleek, low, and 4.30 gears? Meh! Mod, lift, and 4.88s - if it's worth doing, it's worth overdoing!

Rolling a truck (admittedly out of ignorance and lack of skill) has a way of making you prioritize keeping CoG low.

Edit: to those in a rolling vehicle, HANDS INSIDE AT ALL TIMES UNTIL THE VEHICLE COMPLETELY STOPS MOVING. I thought it was done, and staring at the ground a foot away from my face, put my hand out on the ground to brace because I was hanging from the belts. Well it teetered back and the a-pillar pinned my hand to the fortunately soft ground. 3" away was a very large rock and totally different outcome. It continued to teeter and I got my hand out with only a sprained wrist and popped vein, but could have been life-changing.

Edit 2: this is getting off-topic. To tie it back though.. those installing lockers, they can take you places you shouldn't be! It's a VERY powerful mod. So be careful with that power.

Last edited:

Similar threads

- Replies

- 33

- Views

- 2K

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)