I got the engine running for 15 minutes today. The idle was a bit rough but nevertheless... Luckily there's a bunch of threads in here with things to try out for improving the idling.

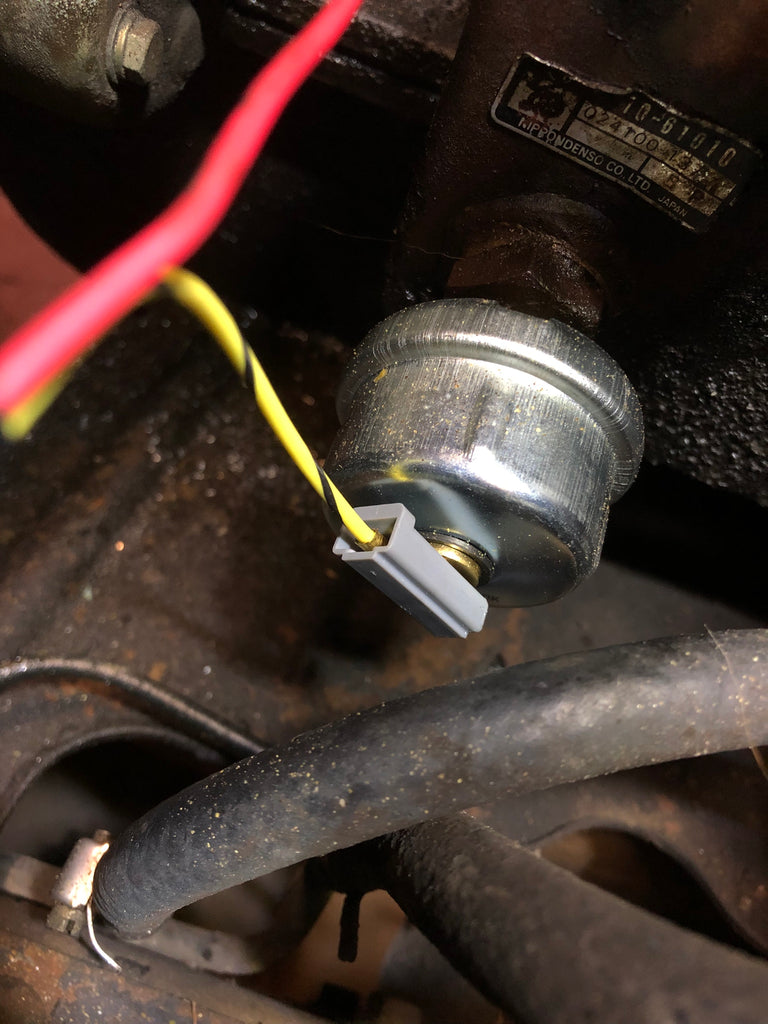

I also realized that the oil pressure sensor wasn't properly connected. Got that fixed and boom, oil pressure was showing on the dash. Same story with the coolant temperature. However I did find it a bit odd, that the lowest positioned coolant hose still felt a bit cold. I was wondering if there was no circulation. But if there hadn't been circulation I'm pretty sure I would've been hearing knocking sounds and felt the engine overheat. As well as seeing the oil pressure rise. So there must be circulation. No?

I was about to install the brake booster till I realized how bad the condition was. So I detached the cylinder, took it to the wire brush and gave it a bit of brake caliper paint. Hope it will turn out well! I took apart the brake cylinder and man was I glad I did so. There was a lot of dirt in there. I managed to find an overhaul kit for 50 USD for the cylinder.

Tomorrow is a day off. Going diving for lobsters with a bunch of friends in the cold waters of Denmark.

For repairing the oil pressure sensor and the coolant temperature sensor properly I need some parts that Vintageteqparts.com has. However they don't ship to Denmark, so I wrote them a message asking nicely... Keeping my fingers crossed.

View attachment 3292514View attachment 3292515View attachment 3292516