CCOT Quarter Panels: has anyone done thread on this?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CCOT Quarter Panels: has anyone done thread on this?

- Thread starter KY Longhunter

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?DanS HJ-45

SILVER Star

I'm about to. Seriously. I was planning on cutting the spot welds tomorrow.

I've also got a new outer rocker to put on, and a new sill (along with a bit of floor repair).

It'd be great if anyone here has any tips or things to watch out for before I go about tearing it up with the plasma cutter.

Dan

I've also got a new outer rocker to put on, and a new sill (along with a bit of floor repair).

It'd be great if anyone here has any tips or things to watch out for before I go about tearing it up with the plasma cutter.

Dan

- Thread starter

- #3

Good Luck..

How bad is your rust? What year truck will you be repairing?

I will be watching.

How bad is your rust? What year truck will you be repairing?

I will be watching.

Dan - What sill are you installing - did you buy the CCOT? What year and how's the build quality of the sill? Does it measure (gauge, etc.) up to the stock stuff you're replacing? Thanks for any info.I'm about to. Seriously. I was planning on cutting the spot welds tomorrow.

I've also got a new outer rocker to put on, and a new sill (along with a bit of floor repair).

It'd be great if anyone here has any tips or things to watch out for before I go about tearing it up with the plasma cutter.

Dan

DanS HJ-45

SILVER Star

How bad is your rust? What year truck will you be repairing?

I will be watching.

The rear sill wasn't actually attached to the frame, but that was the worst of it. It was actually pretty rust free, but a bit banged up and bondo'd to look OK. I did a few patch panels, and realized how tweaked the quarters were, so new one's were ordered.

Here's the last day we drove it... You can clearly see the crease in the quarter here. It got a LOT worse after I replaced some other metal and became much more noticeable. Workable, but the problem we had is that it had already been worked more than I'd like in the past.

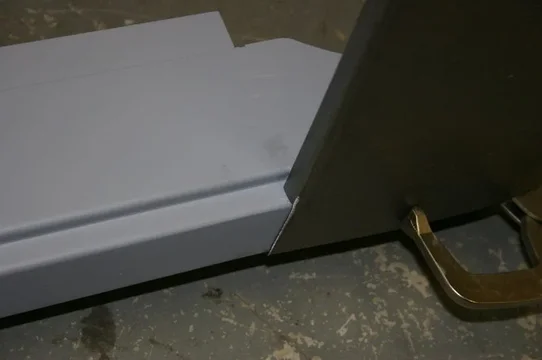

Here's the rear sill (you can see how thin the rest of it is, even if it looks OK from the outside)

And here's what I saw when I opened the box from CCOT.

It's a '79 BTW. All I was going to do was remove the tub to make it easier for the engine swap (see the sig), but finding the cancer makes me not feel right about not fixing it.

Dan

Last edited:

DanS HJ-45

SILVER Star

Dan - What sill are you installing - did you buy the CCOT? What year and how's the build quality of the sill? Does it measure (gauge, etc.) up to the stock stuff you're replacing? Thanks for any info.

CCOT because they sold a complete sill. I'm kind of big on that for a little modification I have in mind. (stay tuned). I really like the idea of having the complete quarter panels, including the upper channels, so that there would be no seam welding, just spot welding. But since I was already ordering from CCOT, I figured I might as well get it all in one shipment.

I'll post up a TON of pics tomorrow as I get the stuff out of the boxes and can really compare it to what's on the truck now. Initial impressions are that the panels and sill are well made. We'll see how close they match up to the truck real soon. This truck was pretty danged straight, and the frame is spot on perfect, so I've got a good "pattern" to work with.

Dan

I bought these, they're great. Waiting to install after I buy the new rear sill......CCOT is about 25 minutes from my casa.

- Thread starter

- #8

...

Dan,

I was considering buying quarters with rail and wheel wells already attached from another vendor and then CCOT's rear sill, but it was suggested not mix matching vendors by someone here on mud.

I don't really know why that should make a difference, but at this point I will hold off on my desire to order something and watch your progress.

My 40 is an '81, so should be exactly the same process.

No hurry, but I am anxiously waiting!

AR

Dan,

I was considering buying quarters with rail and wheel wells already attached from another vendor and then CCOT's rear sill, but it was suggested not mix matching vendors by someone here on mud.

I don't really know why that should make a difference, but at this point I will hold off on my desire to order something and watch your progress.

My 40 is an '81, so should be exactly the same process.

No hurry, but I am anxiously waiting!

AR

DanS HJ-45

SILVER Star

Midday break for me... Pictures are downloading to the computer as I type this...

I'm a bit perplexed actually at a few of the choices CCOT made on the rocker panels especially. They are cut to fit the doorjamb--sort of. They fall about 1.5" short of the actual door opening, which means I have to put the seam in the body panels in right about the same spot as the flange that it all spot welds to. It'll look fine on the outside, but frankly, I'd rather have a single, smooth piece of steel to run along that flange. It would be more rust-proof like that. Also, if it weren't for the seams, I'd rather just spot weld the bits on, and leave the dimples like they were originally. I'm just not too keen on filler to smooth stuff like that out--and these panels are definitely designed to get some body filler to smooth them out. Not a big deal, but another couple inches of steel (and it is surely on the cutting room floor) would have given me a natural place to weld the rocker panel (right where the door jamb is. I personally think it's easier to come up with a good looking corner than a sheet.

Ding! Pictures are done. Here's three pics of what I'm talking about here...

I'm a bit perplexed actually at a few of the choices CCOT made on the rocker panels especially. They are cut to fit the doorjamb--sort of. They fall about 1.5" short of the actual door opening, which means I have to put the seam in the body panels in right about the same spot as the flange that it all spot welds to. It'll look fine on the outside, but frankly, I'd rather have a single, smooth piece of steel to run along that flange. It would be more rust-proof like that. Also, if it weren't for the seams, I'd rather just spot weld the bits on, and leave the dimples like they were originally. I'm just not too keen on filler to smooth stuff like that out--and these panels are definitely designed to get some body filler to smooth them out. Not a big deal, but another couple inches of steel (and it is surely on the cutting room floor) would have given me a natural place to weld the rocker panel (right where the door jamb is. I personally think it's easier to come up with a good looking corner than a sheet.

Ding! Pictures are done. Here's three pics of what I'm talking about here...

DanS HJ-45

SILVER Star

But, to backtrack...

Here's the quarter panels as they came out of the box. They were very well protected for shipping, BTW.

An overview

Here's the right quarter clamped up with the original. It fits very nicely. The wheel wells are right where they should be, as is the filler neck opening and the marker light hole (even if it is rectangular, and the original has rounded corners)

Here's one spot where the CCOT unit differs from the original. Where the quarter meets the sill, the CCOT unit is simply cut off vertically. The original piece is curved to match the opening for the ambulance door.

Here's the quarter panels as they came out of the box. They were very well protected for shipping, BTW.

An overview

Here's the right quarter clamped up with the original. It fits very nicely. The wheel wells are right where they should be, as is the filler neck opening and the marker light hole (even if it is rectangular, and the original has rounded corners)

Here's one spot where the CCOT unit differs from the original. Where the quarter meets the sill, the CCOT unit is simply cut off vertically. The original piece is curved to match the opening for the ambulance door.

DanS HJ-45

SILVER Star

The quarter panels lower flange, from the underside. It is real nice and smooth, no cuts for relief or anything. Was worried that their process might leave this flange open to collecting more dirt (and thus rust) than the original, but happily that is not the case.

And here's the rockers as they come out of the box. They even included some weatherstripping (which is odd, as their rockers don't extend to meet the door itself), and a license plate frame if you're into that sort of thing (I'm not).

And a quick close up of the forward edge of the rockers. This matches the OEM unit perfectly.

And here's the rockers as they come out of the box. They even included some weatherstripping (which is odd, as their rockers don't extend to meet the door itself), and a license plate frame if you're into that sort of thing (I'm not).

And a quick close up of the forward edge of the rockers. This matches the OEM unit perfectly.

DanS HJ-45

SILVER Star

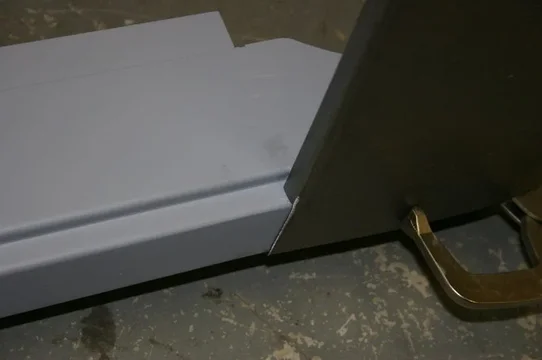

Here's some of the sill, since I know that's what a lot of people really want to see.

It seems very well made to me. The full weld beads are a nice touch for rust prevention IMHO.

An overview...

The inside corner. Note the full weld beads.

And the front (actually rear I guess) of the sill. The bolt holes all match the original spots nicely, all the captive nuts are in place (for the door striker they are even floating--another nice and important touch)

It seems very well made to me. The full weld beads are a nice touch for rust prevention IMHO.

An overview...

The inside corner. Note the full weld beads.

And the front (actually rear I guess) of the sill. The bolt holes all match the original spots nicely, all the captive nuts are in place (for the door striker they are even floating--another nice and important touch)

DanS HJ-45

SILVER Star

And here's where the vertical CCOT quarter mates to the CCOT sill. I think it's good enough, so I won't mess with making the curved bit on the quarter, but we'll see what I think as I go along.

But here's a real oddity to me. Maybe someone who has done this can chime in...

CCOT quarters. CCOT sill. Gap. If the sill weren't correct for the '79, I would think that maybe the earlier models or something had a different curve for the corners, but this is certainly a '79 sill. And the quarters seem to fit the tub on the truck just right... If it weren't for the flange on the bottom of the quarter, I think it'd be pretty easy to work the panel to the sill (but I haven't cut enough of the old quarters off yet to hold the sill up to them to see if the CCOT sill I got matches the original corners. Hopefully I can do that this afternoon.

Here it is from a slightly different angle, still showing that gap (1/2" or so!!)

I'm off to town to see if I can't buy some more or better spotweld cutters. The "premium" ones I got from Eastwood haven't been able to do more than maybe 15 spots each, and I've got a lot to drill out to get the quarters off. Should have bought the Blair, methinks. I'm hoping the local bodyshop will have some.

I'll post more on this tonight.

Dan

But here's a real oddity to me. Maybe someone who has done this can chime in...

CCOT quarters. CCOT sill. Gap. If the sill weren't correct for the '79, I would think that maybe the earlier models or something had a different curve for the corners, but this is certainly a '79 sill. And the quarters seem to fit the tub on the truck just right... If it weren't for the flange on the bottom of the quarter, I think it'd be pretty easy to work the panel to the sill (but I haven't cut enough of the old quarters off yet to hold the sill up to them to see if the CCOT sill I got matches the original corners. Hopefully I can do that this afternoon.

Here it is from a slightly different angle, still showing that gap (1/2" or so!!)

I'm off to town to see if I can't buy some more or better spotweld cutters. The "premium" ones I got from Eastwood haven't been able to do more than maybe 15 spots each, and I've got a lot to drill out to get the quarters off. Should have bought the Blair, methinks. I'm hoping the local bodyshop will have some.

I'll post more on this tonight.

Dan

- Thread starter

- #14

Here's one spot where the CCOT unit differs from the original. Where the quarter meets the sill, the CCOT unit is simply cut off vertically. The original piece is curved to match the opening for the ambulance door.

View attachment 304765

They sell a Corner Channel piece for about $110 that addresses the curved portion.

Don't know how neccessary it is. Really depends on how original you want it to look.

- Thread starter

- #15

Did the curve in the OEM sill meet the quarter panel through the whole curve?

I wouldn't know as mine had a PO hack job already done.

Thanks for all the pics and info.

I think you may need to buy the corner channels to make the curved portion of amby door opening.

As far as the rockers you could have cut your own and saved some dinero.

Oh well, it looks pretty darn good. Maybe all that shiny rust free metal is worth it.

I wouldn't know as mine had a PO hack job already done.

Thanks for all the pics and info.

I think you may need to buy the corner channels to make the curved portion of amby door opening.

As far as the rockers you could have cut your own and saved some dinero.

Oh well, it looks pretty darn good. Maybe all that shiny rust free metal is worth it.

But here's a real oddity to me. Maybe someone who has done this can chime in...

View attachment 304774

CCOT quarters. CCOT sill. Gap. If the sill weren't correct for the '79, I would think that maybe the earlier models or something had a different curve for the corners, but this is certainly a '79 sill. And the quarters seem to fit the tub on the truck just right... If it weren't for the flange on the bottom of the quarter, I think it'd be pretty easy to work the panel to the sill (but I haven't cut enough of the old quarters off yet to hold the sill up to them to see if the CCOT sill I got matches the original corners. Hopefully I can do that this afternoon.

Here it is from a slightly different angle, still showing that gap (1/2" or so!!)

View attachment 304775

I'm off to town to see if I can't buy some more or better spotweld cutters. The "premium" ones I got from Eastwood haven't been able to do more than maybe 15 spots each, and I've got a lot to drill out to get the quarters off. Should have bought the Blair, methinks. I'm hoping the local bodyshop will have some.

I'll post more on this tonight.

Dan

DanS HJ-45

SILVER Star

Did the curve in the OEM sill meet the quarter panel through the whole curve?

I wouldn't know as mine had a PO hack job already done.

Thanks for all the pics and info.

I think you may need to buy the corner channels to make the curved portion of amby door opening.

As far as the rockers you could have cut your own and saved some dinero.

Oh well, it looks pretty darn good. Maybe all that shiny rust free metal is worth it.

Corners not so much hacked, more like banged and bondoed.

I like the little flange at the front of the rockers, as I couldn't fab that up with my brake, but the rest of them isn't anything that special. I could have easily made the same in about an hour, but I guess I was thinking that they were at least right up to the door sill. Also, they were on sale. On my 45, I will NOT buy CCOT rockers. The flat section of metal isn't the hard part to fab.

I will look into the curved channel bit. I just didn't notice it when I ordered or something.

Anyway, I bought some Blair spotweld cutters in town, and I'm off to the shop again to rip stuff up!

Dan

- Thread starter

- #17

updates?

DanS HJ-45

SILVER Star

updates?

Yeah. Typing this update is delaying me from getting back up to the shop to get any more done.

First off: buy the Blair spotweld cutters. Worth every penny. MUCH better than the Eastwood "premium" cutters I had bought earlier. Less expensive too, the local paint and body shop had the arbor for about $15, and a box of three cutting heads for about another $15.

The rocker is out. I have the trimming to fit the new one pretty much done. I will need to do some rust repair on the flange that the rocker attaches to.

I also got all the spotwelds on the right quarter panel drilled out. I'm getting real close to pulling the whole mother off.

Here's three pics of the rocker clamped into place. I will need to push and pull some metal to make it all line up straight again, as the gouge in the original obviously tweaked the rocker a good bit.

DanS HJ-45

SILVER Star

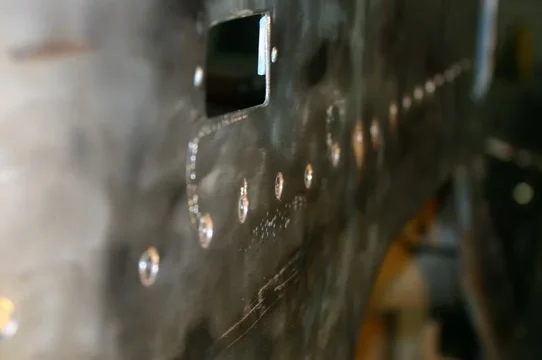

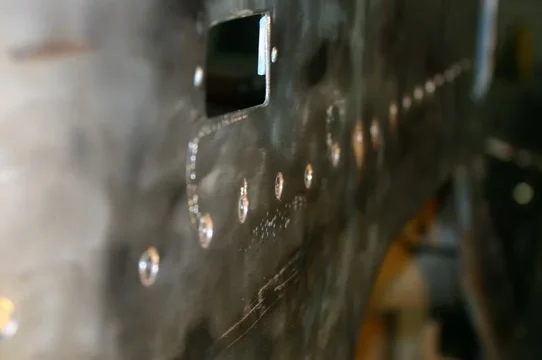

And here's the row of spotwelds cut out...

And a detail pic of the corner pieces we were talking about.

The CCOT $110 piece is actually the bit between the sill and the quarter panel's rounded piece. Mine are fine (well, one needs just a little rust repair, but not worth $110), so I think I'll leave them as is. I'll just have a vertical line across the sill at the end of the quarter, instead of the nice curved bit Toyota used.

That's it for now. My truck is warmed up and I'm ready to go cut some more metal up!

Dan

And a detail pic of the corner pieces we were talking about.

The CCOT $110 piece is actually the bit between the sill and the quarter panel's rounded piece. Mine are fine (well, one needs just a little rust repair, but not worth $110), so I think I'll leave them as is. I'll just have a vertical line across the sill at the end of the quarter, instead of the nice curved bit Toyota used.

That's it for now. My truck is warmed up and I'm ready to go cut some more metal up!

Dan

Similar threads

- Replies

- 19

- Views

- 2K

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)