mudgudgeon

Resident galah

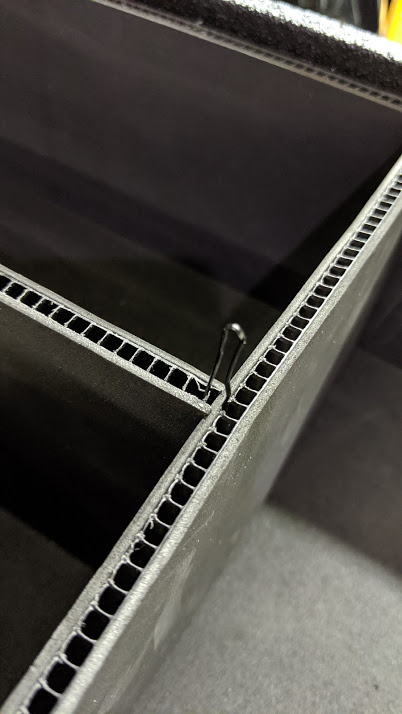

Here is the board attached with the pins

Took a few hours, but I'm really happy how it turned out.

Here is the bottom drawer. I used 6" high pieces, so the ability to customize by doing it yourself was well worth it. I think TP only has some pieces a bit over 4"

View attachment 1998399

So, total cost of materials for both drawers was around $80. This was $40 for the 6mm high density foam on the bottom of the drawers and $40 in divider materials from the craft store.

I did some rough calculations on the TrekPac and I would have had to spend well over $600 in their individual divider kits.

This is obviously not as nice as the TrekPak product, but I'm happy with the results.

Cheers,

john~

Clever.

Shame you didn't wrap the foam as a single piece from one side to the other over the top edge