Did you use an alignment tool to line the clutch disk and pilot bearing?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Biscuit's Keeping The FJ40 - Customization/Improvement Thread

- Thread starter Biscuit

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?- Thread starter

- #62

Did you use an alignment tool to line the clutch disk and pilot bearing?

Good question I didn't answer above. I did use an alignment tool. I removed the alignment tool (plastic one) immediately before the first attempted installation.

I just checked with the alignment tool again, and there was some resistance in the pilot bearing both inserting and removing the tool.

I'm starting to think honing down the tip of the input shaft more may be the solution here. My guess is that during the bearing install the internal diameter was decreased just enough to cause problems.

Last edited:

- Joined

- Apr 14, 2004

- Threads

- 1,468

- Messages

- 36,684

- Location

- 818-953-9230

- Website

- www.marksoffroad.net

No Mike, install will not affect I.D. On a roller bearing with a separate inner race.

If it is off center just a little bit, you can try depressing the clutch pedal once everything is positioned, giving the disc enough 'wiggle' to get the tip of the input centered onto the pilot bearing.

Also it is VERY important to remember that distance around the bellhousing must be equal. I often use things like tool handles as handy gauges to see if trans and bellhousing faces are parallel.

Sent from my iPad in rural Ridgecrest!

If it is off center just a little bit, you can try depressing the clutch pedal once everything is positioned, giving the disc enough 'wiggle' to get the tip of the input centered onto the pilot bearing.

Also it is VERY important to remember that distance around the bellhousing must be equal. I often use things like tool handles as handy gauges to see if trans and bellhousing faces are parallel.

Sent from my iPad in rural Ridgecrest!

- Thread starter

- #64

Sent from my iPad in rural Ridgecrest!

Thanks for the remote tech tip.

Transmission is in!

The chain hoist worked great for the lift and the spare long t-case to tranny bolts worked well for alignment.

The chain hoist worked great for the lift and the spare long t-case to tranny bolts worked well for alignment.Tomorrow will be sorting the linkages and emergency brake.

- Thread starter

- #65

Didn't get too much done today.

I disassembled the e-brake assembly and installed new pads. The old pads weren't that worn, but I chose to replace them for two reasons.

I disassembled the e-brake assembly and installed new pads. The old pads weren't that worn, but I chose to replace them for two reasons.

- Might as well replace them while I have everything disassembled.

- The old pads were somewhat saturated with oil. Not catastrophically, so the old ones are being saved as spares.

- Thread starter

- #66

After not having time to work on the 40 for the past month and a half, I finally got some wrench time today.

I found the t-case saver, it has been cleaned and got a fresh coat of paint.

The t-case input tail cone is on with the OEM bolts as it the PTO cover with new JIS bolts.

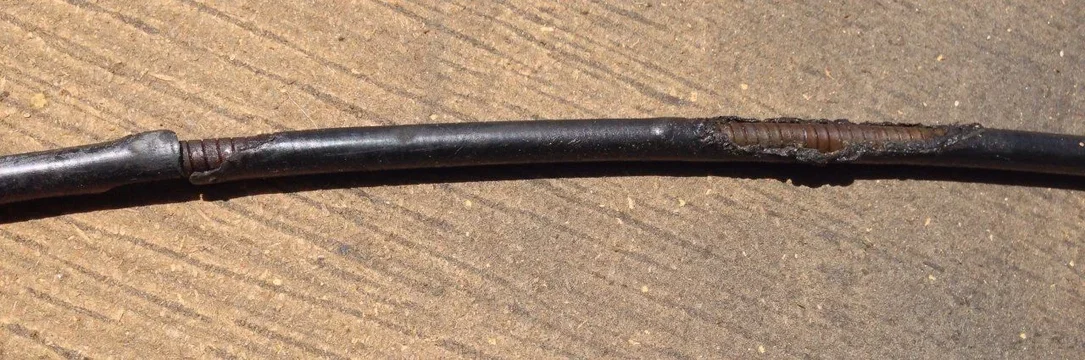

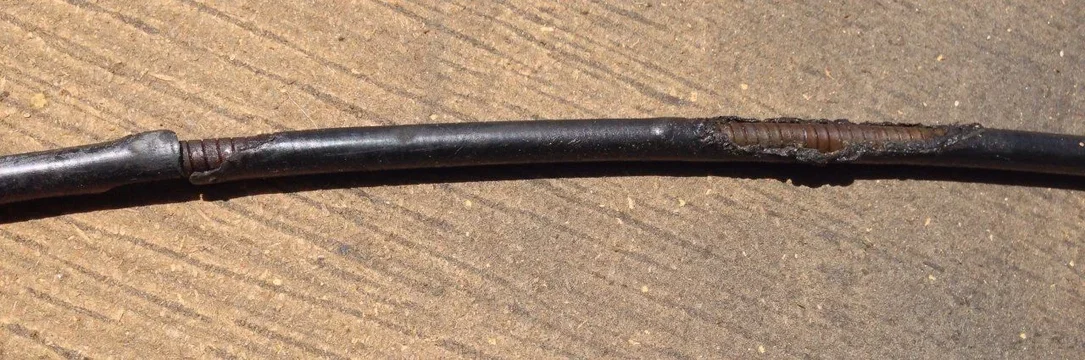

I installed the e-brake backing plate and checked the length of the e-brake cable. It looks like my old cable will reach the e-brake just fine. After cleaning the e-brake cable

I found the plastic cover was cracked lengthwise in one location and split circumferentially in another. I think this damage could be repaired with some heavy duty heat shrink tubing. The point of the plastic cover is to keep water/oil/dirt/debris out of the actual cable.

I found the t-case saver, it has been cleaned and got a fresh coat of paint.

The t-case input tail cone is on with the OEM bolts as it the PTO cover with new JIS bolts.

I installed the e-brake backing plate and checked the length of the e-brake cable. It looks like my old cable will reach the e-brake just fine. After cleaning the e-brake cable

I found the plastic cover was cracked lengthwise in one location and split circumferentially in another. I think this damage could be repaired with some heavy duty heat shrink tubing. The point of the plastic cover is to keep water/oil/dirt/debris out of the actual cable.

Last edited:

Annother option would be 3M electrical splicing tape. A layer or two would keep crap out.

- Thread starter

- #68

I'm thinking of using this: heavy wall heat shrink tubing (link to Amazon)

The cable is about 3/8" diameter with the plastic covering. The flexible metal part appears to be ~1/4" from the exposed area. This way I can cover both broken sections with a single repair covering.

The cable is about 3/8" diameter with the plastic covering. The flexible metal part appears to be ~1/4" from the exposed area. This way I can cover both broken sections with a single repair covering.

- Thread starter

- #69

The heavy wall heat shrink tubing worked great. After shrinking the wall of the tubing is very thick, but still flexible enough. I used a single section about 12" long to cover all the damage on the old covering.

I was hoping to get more done this weekend but had some work issues come up on Sunday that took precedence. I'm going to try to futz on the e-break in the evenings and get it fully assembled in the next week.

I was hoping to get more done this weekend but had some work issues come up on Sunday that took precedence. I'm going to try to futz on the e-break in the evenings and get it fully assembled in the next week.

Looking good man, keep it up biscuit.

- Thread starter

- #71

- Thread starter

- #72

More slow steady progress this evening. The output shaft castle nut is tightened to spec and secured. The t-case linkage is assembled.

I measured for driveshafts and came up with 28" for the front and 21" for the rear as it sits. Of my remaining 3 speed shafts one is 26" fully compressed so that may be usable for the front.

My choices for the rear shaft are:

I measured for driveshafts and came up with 28" for the front and 21" for the rear as it sits. Of my remaining 3 speed shafts one is 26" fully compressed so that may be usable for the front.

My choices for the rear shaft are:

- Have the shorter drive shaft I have shortened to 21"

- Find a set of drive shafts from a 4 speed 1974 FJ40

- Order custom

- Joined

- Apr 14, 2004

- Threads

- 1,468

- Messages

- 36,684

- Location

- 818-953-9230

- Website

- www.marksoffroad.net

Before you spend $$ on #1, make sure the slip spline is worth reusing. Pull the yoke out about an inch and a half from full compression and try rocking the two halves of the shaft in opposite directions to check the splines for wear.

- Thread starter

- #74

Before you spend $$ on #1, make sure the slip spline is worth reusing. Pull the yoke out about an inch and a half from full compression and try rocking the two halves of the shaft in opposite directions to check the splines for wear.

The longer driveshaft has no play. The shorter driveshaft has a very very small amount of play, seemed like less than 1deg rotational.

I would just take em to a driveline shop and have em cut or lengthened to what you want. New shafts will be way more money.

- Thread starter

- #76

The starter is reinstalled.

I checked the operation of the transfer case shift linkage and it seems to have excessive travel. When in H4 the t-case lever is very close to the transmission shift lever. Pics of the t-case in all three standard positions are below. If I can lengthen the linage between the lever and the high-low selector arm, I should be able to move the lever to the left for all sift positions, I'm just not sure how adjustable that part of the linkage is.

2wd Dive High

4wd High

4wd Low

I checked the operation of the transfer case shift linkage and it seems to have excessive travel. When in H4 the t-case lever is very close to the transmission shift lever. Pics of the t-case in all three standard positions are below. If I can lengthen the linage between the lever and the high-low selector arm, I should be able to move the lever to the left for all sift positions, I'm just not sure how adjustable that part of the linkage is.

2wd Dive High

4wd High

4wd Low

Last edited:

- Thread starter

- #77

Tightening up the arm off the high low selector lever seemed to improve things. I'm going to test fit the transmission hump and see what it looks like.

- Thread starter

- #78

The transmission and transfer case are filled with gear oil. I filled them until oil was at the level of the fill plug.

Rear driveshaft is half way bolted in (will roll the truck back to rotate it 180deg.

Right now I am working on how to route the speedometer and e-brake cables (disconnected at firewall side). I had them originally routed up and over the clutch fork, but it appears that there will not be enough room with the transmission hump on. Does anyone know if they are supposed to route outside of the frame rail?

Rear driveshaft is half way bolted in (will roll the truck back to rotate it 180deg.

Right now I am working on how to route the speedometer and e-brake cables (disconnected at firewall side). I had them originally routed up and over the clutch fork, but it appears that there will not be enough room with the transmission hump on. Does anyone know if they are supposed to route outside of the frame rail?

- Thread starter

- #79

Went to put the transmission hump back on and found that the shift tower on the 4speed is forward and to the left of the 3 speed. I can get the hump to drop into place, but it is completely out of alignment with the holes on the floor.

Specter lists the 4-speed transmission hump that is specific to the 73-74 4-speed FJ40s since 1974 was a transition year.

I'm thinking some surgery may be in store for my hump. That should delay return to service from late afternoon until mid-July.

Specter lists the 4-speed transmission hump that is specific to the 73-74 4-speed FJ40s since 1974 was a transition year.

I'm thinking some surgery may be in store for my hump. That should delay return to service from late afternoon until mid-July.

Last edited:

- Thread starter

- #80

Doing some research the '75-'78 transmission humps should bolt up to the 74 tub. The only different I can fathom for the 1974 transmission hump is the location of the transfer case shift lever hole from the transition case that was used ing 74.

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)