This will be a "build thread" of sorts. Hopefully it will keep me motivated to keep moving forward with the various projects on my 40. Also it will allow me to share what I have going on.

I have many projects in mind; some big, some small, some in the middle, and some that may not happen at all.

I give you: Biscuit's 2013 Project List (in no particular order)

And as a goal, I'd like the downtime for each project to be no-more than two weeks.

I have many projects in mind; some big, some small, some in the middle, and some that may not happen at all.

I give you: Biscuit's 2013 Project List (in no particular order)

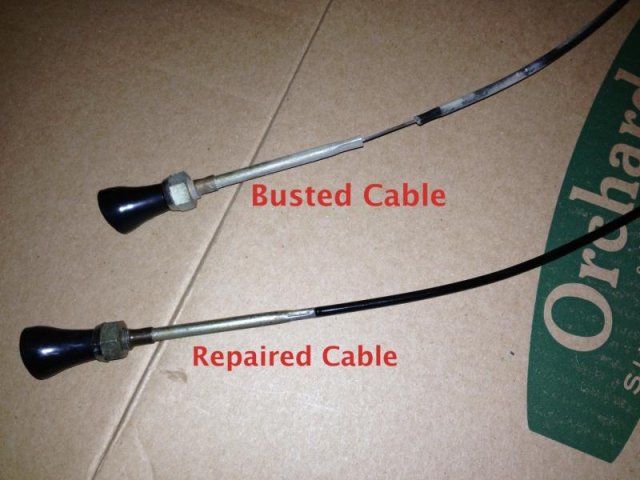

- [STRIKE]Repair (second) Fresh Pull Cable[/STRIKE] Done!

- Repair or Replace Front Heater

- Overhaul Wiring Harness

- [STRIKE]Replace Transfer Case Front Drive Bearing[/STRIKE]

- [STRIKE]Replace Seals On Transmission & Transfer Case[/STRIKE] Now swap in H42. In Progress

- Rebuild E-Break

- Build A New Rear Storage Platform That Is K9 Friendly (dog on top of the platform)

- Actually Drive On Dirt This Year

- Reinstall skid plates for the first time since the new engine

- Redo or replace front seats

- Install amauer's kit for Autometer gauges in a stock cluster, and if possible have custom gauge faces cut out of sheet so I can make OEM-look markings for the Autometer gauges

And as a goal, I'd like the downtime for each project to be no-more than two weeks.

Last edited:

. Depending on how that all goes down, some projects may end up being delayed to 2014. (Even worse buying a house is in the trade space for this, and the 40 may have to be sacrificed to help boost the down payment as a last resort

. Depending on how that all goes down, some projects may end up being delayed to 2014. (Even worse buying a house is in the trade space for this, and the 40 may have to be sacrificed to help boost the down payment as a last resort  . Lousy insane SoCal home prices.)

. Lousy insane SoCal home prices.)