Well. We had our ration of sunshine for the day. (Less than an hour.) Back to drizzle now. Anyone would think this was Ireland or the Yorkshire Moors instead of NZ!

. ... No offence meant to the Irish either. I actually like moss and the colour green. None of us suffer bush fires either! And I know the Yorkshire Moors is lot more than just a place where bodies are buried.

)

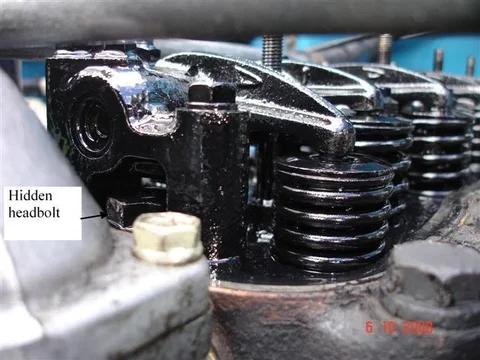

No chance of doing the tappets now. It's almost 4pm and I'm cooking tea tonight because

has had enough of me and run away to her mother's (way up north) for a week! (Yeah. So you're right. I'm actually cooking tea all week!)

Time enough to get another cruiser job out of the way today though. ---- Or perhaps "out of the way" is being too optimistic considering how long I have been working on this task.

See this pretty braided stainless hose here : (The larger of the two)

It keeps dripping dirty black engine oil on top of my lovely oil filter housing like so:

And that hose is a bit like the "rogue taps" that another age-compromised colleague used to ramble on about. (A rogue tap is one that defies all attempts at stopping it from dripping and shows no sign of any wear /damage that may be causing the drip!)

I have had that hose immersed in water under air pressure and seen no sign whatsoever of bubbles! I've also swapped from copper washers to fibre ones at the banjos in yet another futile attempt at stemming the oil seepage.

So this last week (in desperation) I ordered a complete replacement hose at the huge expense of $61.59 NZ.

(The twisted hose is the old one -or old new-one - that I suspect of leaking.)

All my previous braided stainless hoses from this outfit were made up with teflon inner hose which is pretty stiff and unflexible really. (They reckoned it was the best material back then.)

This time I asked them to get the "same degree of twist" between inlet and outlet banjos (because I remember having quite some difficulty twisting the previous teflon hoses to get them to fit).

Anyway - Now they have mysteriously supplied me a "rubber Auto Flex" inner hose instead of teflon. (Actually feels much better because it flexes far more easily.) And they used the banjos from my sample hose (the original ex-factory Toyota ones) saying they couldn't obtain new ones in that sizing. (Strange! They obtained them OK before?)

Since they destroyed my sample hose - I no longer had a hose to compare the new one against to ensure they got the length and "banjo twist" correct. (Cunning bastards!)

And in case anyone wonders why I PAID to get a replacement hose for one that I suspect of being faulty (rather than asking for a replacement under warranty) - the reason is because I couldn't confirm the leak (with the immersion testing) and therefore I can't garantee that they supplied a faulty product. (Another way of saying this is that "I don't have full confidence in my opinion that their hose is leaking".)

So now the new new-hose is fitted and I've gone back to using copper washers on the banjos. And as I've been typing this - the cruiser's been running in the driveway (annoying the neighbours). - So far there's no sign of any oil weepage but it is very "early days" yet.

Fingers crossed.

. ... No offence meant to the Irish either. I actually like moss and the colour green. None of us suffer bush fires either! And I know the Yorkshire Moors is lot more than just a place where bodies are buried.

. ... No offence meant to the Irish either. I actually like moss and the colour green. None of us suffer bush fires either! And I know the Yorkshire Moors is lot more than just a place where bodies are buried. has had enough of me and run away to her mother's (way up north) for a week! (Yeah. So you're right. I'm actually cooking tea all week!)

has had enough of me and run away to her mother's (way up north) for a week! (Yeah. So you're right. I'm actually cooking tea all week!)