- Thread starter

- #101

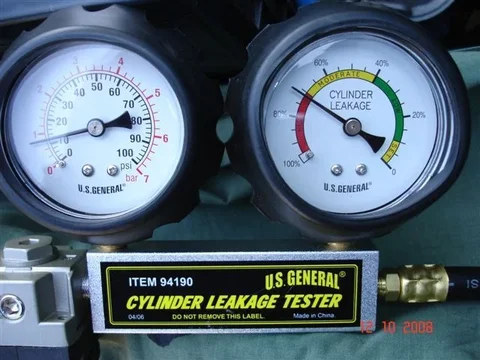

Now you will see that the LH gauge reads around 15 psi. So that is actually the maximum pressure that this tool can apply to any cylinder it is testing! Yep - A measerly 15 psi!!!! But with just 15 psi - the Leakage Tester seems to do a far better job at diagnosing my engine than my Compression Tester did! (  Perhaps I should just say - It is less prone to operator-error?)

Perhaps I should just say - It is less prone to operator-error?)

Once you have set/callibrated the tool in this way, you then connect it to the cylinder you are testing. And I did this using the hose supplied together with that fitting I made from an old glowplug (shown at the start of this thread).

The results I got were rather alarming (for No.2 cylinder)!

No. 1 - 33% (within "low leakage" band = good)

No. 2 - 72% (just into "high leakage" band = bad)

No. 3 - 55% (in "moderate leakage" band)

No.4 - 46% (in "moderate leakage" band)

And I could easily hear the air leaking into the crankcase from No.2 cylinder!

By the way - With the tappet/rocker cover removed, I had no problem getting "each piston near TDC with both its cylinder's valves closed". And I put the gearbox in 4th to stop any engine rotation occuring but I noticed no tendency for that to occur. (Not surprising really because the pressure in the cylinder is under 15 psi).

And I should mention that this tool has some sort of "orifice" inside it. This means that leakage causes the pressure downstream of the orifice (measured by the RH gauge) to fall below the upstream pressure (measured by the LH gauge).

Note: The RH gauge could have been callibrated from 0 to 15 psi but instead (to make things easier for me) it is callibrated in "percentage leagage"

Another thing: - I did notice a tendency for the RH gauge to creep upwards from the "zero mark" when being set/callibrated. (Probably due to a poor quality regulator.) But I found that slight variations in the way I "zero-ed" the tool didn't affect the readings at all. So, in other words, - I have confidence in my readings here.

Here's me checking my "poor" cylinder (No. 2 cylinder):

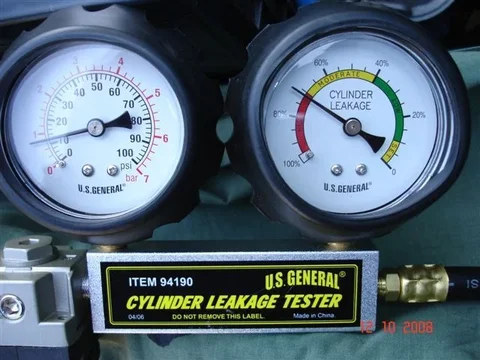

And here is a close-up of the gauges (No. 2 cylinder):

Now before anyone tells me - YES........... I should have squirted some oil into No.2 cylinder and taken a second reading to see if the % loss reduced to an acceptable level. (This would have proven that rings/bore was responsible.) The fact is - I was unfamiliar with using the tool and I think my decision not to use oil with my compression tester stuck in my mind. (Of course the Leakage Tester wouldn't suffer from ingesting the oil - unlike the Compression Tester - so there would have been no "negatives" associated with doing this "wet test".) ------- But I'm NOT going to open her up yet again to correct this oversight because I have NO intention of getting further into engine-work at this point in time.

Now these "Leakage Test results" made me reconsider my "Compression Testing results". ....

And I now believe the first figures (the poorer figures) were the most accurate.

And I now believe the first figures (the poorer figures) were the most accurate.

Here is what the Compression Tester Instructions said:

Now I previously thought the underlined part was "dribble" but in light of my Leakage Test findings, I now believe you MUST put a limit on the number of "compression pulses" that you use to build up to the reading you take with a Compression Gauge. And in retrospect, I believe restricting myself to "8 pulses" for each and every reading would have been appropriate! - Edit 14 Oct - Ignore me here (in this paragraph). This is "garbage".

Perhaps I should just say - It is less prone to operator-error?)

Perhaps I should just say - It is less prone to operator-error?)Once you have set/callibrated the tool in this way, you then connect it to the cylinder you are testing. And I did this using the hose supplied together with that fitting I made from an old glowplug (shown at the start of this thread).

The results I got were rather alarming (for No.2 cylinder)!

No. 1 - 33% (within "low leakage" band = good)

No. 2 - 72% (just into "high leakage" band = bad)

No. 3 - 55% (in "moderate leakage" band)

No.4 - 46% (in "moderate leakage" band)

And I could easily hear the air leaking into the crankcase from No.2 cylinder!

By the way - With the tappet/rocker cover removed, I had no problem getting "each piston near TDC with both its cylinder's valves closed". And I put the gearbox in 4th to stop any engine rotation occuring but I noticed no tendency for that to occur. (Not surprising really because the pressure in the cylinder is under 15 psi).

And I should mention that this tool has some sort of "orifice" inside it. This means that leakage causes the pressure downstream of the orifice (measured by the RH gauge) to fall below the upstream pressure (measured by the LH gauge).

Note: The RH gauge could have been callibrated from 0 to 15 psi but instead (to make things easier for me) it is callibrated in "percentage leagage"

Another thing: - I did notice a tendency for the RH gauge to creep upwards from the "zero mark" when being set/callibrated. (Probably due to a poor quality regulator.) But I found that slight variations in the way I "zero-ed" the tool didn't affect the readings at all. So, in other words, - I have confidence in my readings here.

Here's me checking my "poor" cylinder (No. 2 cylinder):

And here is a close-up of the gauges (No. 2 cylinder):

Now before anyone tells me - YES........... I should have squirted some oil into No.2 cylinder and taken a second reading to see if the % loss reduced to an acceptable level. (This would have proven that rings/bore was responsible.) The fact is - I was unfamiliar with using the tool and I think my decision not to use oil with my compression tester stuck in my mind. (Of course the Leakage Tester wouldn't suffer from ingesting the oil - unlike the Compression Tester - so there would have been no "negatives" associated with doing this "wet test".) ------- But I'm NOT going to open her up yet again to correct this oversight because I have NO intention of getting further into engine-work at this point in time.

Now these "Leakage Test results" made me reconsider my "Compression Testing results". ....

And I now believe the first figures (the poorer figures) were the most accurate.

And I now believe the first figures (the poorer figures) were the most accurate.Here is what the Compression Tester Instructions said:

Now I previously thought the underlined part was "dribble" but in light of my Leakage Test findings, I now believe you MUST put a limit on the number of "compression pulses" that you use to build up to the reading you take with a Compression Gauge. And in retrospect, I believe restricting myself to "8 pulses" for each and every reading would have been appropriate! - Edit 14 Oct - Ignore me here (in this paragraph). This is "garbage".

Last edited: