Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1978 LPB Teardown and Rebuild

- Thread starter Awl_TEQ

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?Awl_TEQ

Supporting Vendor

- Thread starter

- #626

Ah, right - the tube cross member! Here's the skinny. The drum will not allow me to get the crossmember into position. So I took it off for now. Because the drum may need to come off for service at some point the tube will have to move several inches back. At this point I plan to fully remove the tube, patch the holes in the frame rails and hole saw new ones further back. I may have to change the obround frame hole behind the tube into a round hole to gain some real estate.

Awl_TEQ

Supporting Vendor

- Thread starter

- #629

Apologies for the poor photography - the colors blend on the screen

So I want to maintain a stockish look to any alterations I do (ha,ha..) so I want to keep the three ribs directly in the path of the cut. So I will take out 7" in the middle of the ribs and keep the rib ends to weld back together - if that makes sense - and move the original end back that 7". Trouble is the one rib is right in the way of a straight line cut so I will cut wider on the right side in this view.

I'll let the pictures talk

So I want to maintain a stockish look to any alterations I do (ha,ha..) so I want to keep the three ribs directly in the path of the cut. So I will take out 7" in the middle of the ribs and keep the rib ends to weld back together - if that makes sense - and move the original end back that 7". Trouble is the one rib is right in the way of a straight line cut so I will cut wider on the right side in this view.

I'll let the pictures talk

Awl_TEQ

Supporting Vendor

- Thread starter

- #633

cleaned up - left enough material to hammer up a flange

all done phase one

Here I have the cross member set in the stock location. It has to go back in but the fuel tank well is in the way. Since I am removing the tank from the cab I am going to ditch the well as well. I'll cut it out and fab up a panel that matches the other side of the floor. Then I'll move all three pieces of the cross member back 7". Once that is done I'll re-evaluate the stiffness of the floor and act accordingly.

all done phase one

Here I have the cross member set in the stock location. It has to go back in but the fuel tank well is in the way. Since I am removing the tank from the cab I am going to ditch the well as well. I'll cut it out and fab up a panel that matches the other side of the floor. Then I'll move all three pieces of the cross member back 7". Once that is done I'll re-evaluate the stiffness of the floor and act accordingly.

I am so envious of your metal fab skills that I almost don't like you any more... but since you are so cool, I forgive you for making my metal fab skills look like a 4 year old playing with clay...

Why not get rid of the hand brake and go with 60 series axles to avoid having to alter the chassis? Then you get the better handbrake on the rear axle, plus a bit more width for stability. I know many of you guys in the rust belt don't like the rear axle hand brake because it can freeze up from the salt, but what are the chances you will use this as a daily driver in the winter?

That valve cover on the 60 series 3B looks pretty clean. Could you polish that one to put on your engine? Ugly Betty has one sexy example of a polished valve cover.

On a side note, someone at a petrol station today noticed my winch solenoid cover and asked about it. I gave them your info, but they seemed dubious about getting it here from Canada. Let me know if you get anyone contacting you from down here.

Cheers,

Josh

Why not get rid of the hand brake and go with 60 series axles to avoid having to alter the chassis? Then you get the better handbrake on the rear axle, plus a bit more width for stability. I know many of you guys in the rust belt don't like the rear axle hand brake because it can freeze up from the salt, but what are the chances you will use this as a daily driver in the winter?

That valve cover on the 60 series 3B looks pretty clean. Could you polish that one to put on your engine? Ugly Betty has one sexy example of a polished valve cover.

On a side note, someone at a petrol station today noticed my winch solenoid cover and asked about it. I gave them your info, but they seemed dubious about getting it here from Canada. Let me know if you get anyone contacting you from down here.

Cheers,

Josh

crushers

post ho

WOW!!

Very nice work!

Cheers,

Jim

Cheers,

Jim

Awl_TEQ

Supporting Vendor

- Thread starter

- #639

Why not get rid of the hand brake and go with 60 series axles to avoid having to alter the chassis? Then you get the better handbrake on the rear axle, plus a bit more width for stability. I know many of you guys in the rust belt don't like the rear axle hand brake because it can freeze up from the salt, but what are the chances you will use this as a daily driver in the winter?

That valve cover on the 60 series 3B looks pretty clean. Could you polish that one to put on your engine? Ugly Betty has one sexy example of a polished valve cover.

On a side note, someone at a petrol station today noticed my winch solenoid cover and asked about it. I gave them your info, but they seemed dubious about getting it here from Canada. Let me know if you get anyone contacting you from down here.

Cheers,

Josh

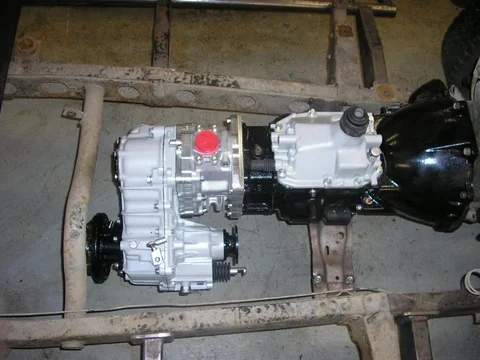

Well... I like 40 series the most. This set up is all 40 series with the exception of the Toybox of course. I don't want too much of a frankenstein rig, though you wouldn't know it from all of my alterations thus far. There is nothing mechanically wrong with my axles. I prefer the dash mounted park brake handle. But mostly this was all a part of my original vision for this build. I have learned a great deal about other options over the last couple of years of surfing MUD and if I started planning today I may just have done things differently. But I will see it through. Other than the Toybox addition it is all going according to plan. This was nearly a 4 door build at one point but I stuck with the plan.

The 60 3B is destined to be a fully rebuilt spare and/or part of a BJ42 fully stock build if I can find a suitable donor. I'm not concerned with under hood looks other than to keep it appearing clean and well sorted.

No other inquiries from downunda right now with the possible exception of a guy who wants a price on a bed. Shipping would be more than the cost of the bed though.

DanS HJ-45

SILVER Star

Kevin: you are awesome. That is all.

Well, that and I am kind of ticked that I don't get any time to go finish up the 40 (let alone start on my 45) anytime soon...

Dan

Well, that and I am kind of ticked that I don't get any time to go finish up the 40 (let alone start on my 45) anytime soon...

Dan

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)