As mentioned, she's got new shoes. Happened upon a brand new tire from Nokian, which is a brand I've had Very good experiences with (WR2 and WR3 for many years while living in the Rockies), and decided to chance it based on the descriptions. Sounds very much like a road focused/oriented tire, with the nicer characteristics, and an A/T "look". I have a similar type tire on the '99 4runner and it's been an outstanding choice so-far.

Only just installed a day ago, and with a whopping 20 miles driven since install so the jury is very much still out on these tires.

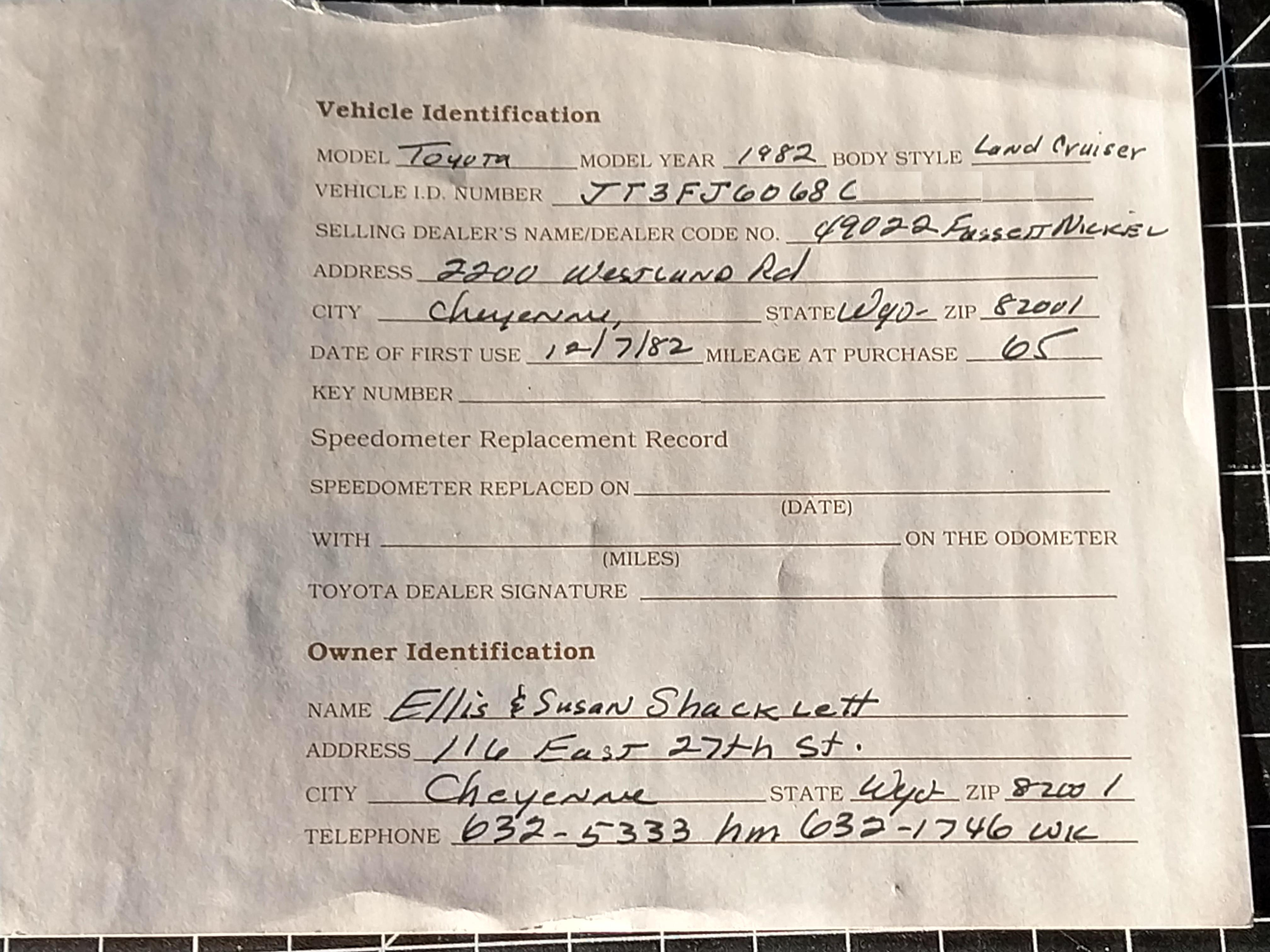

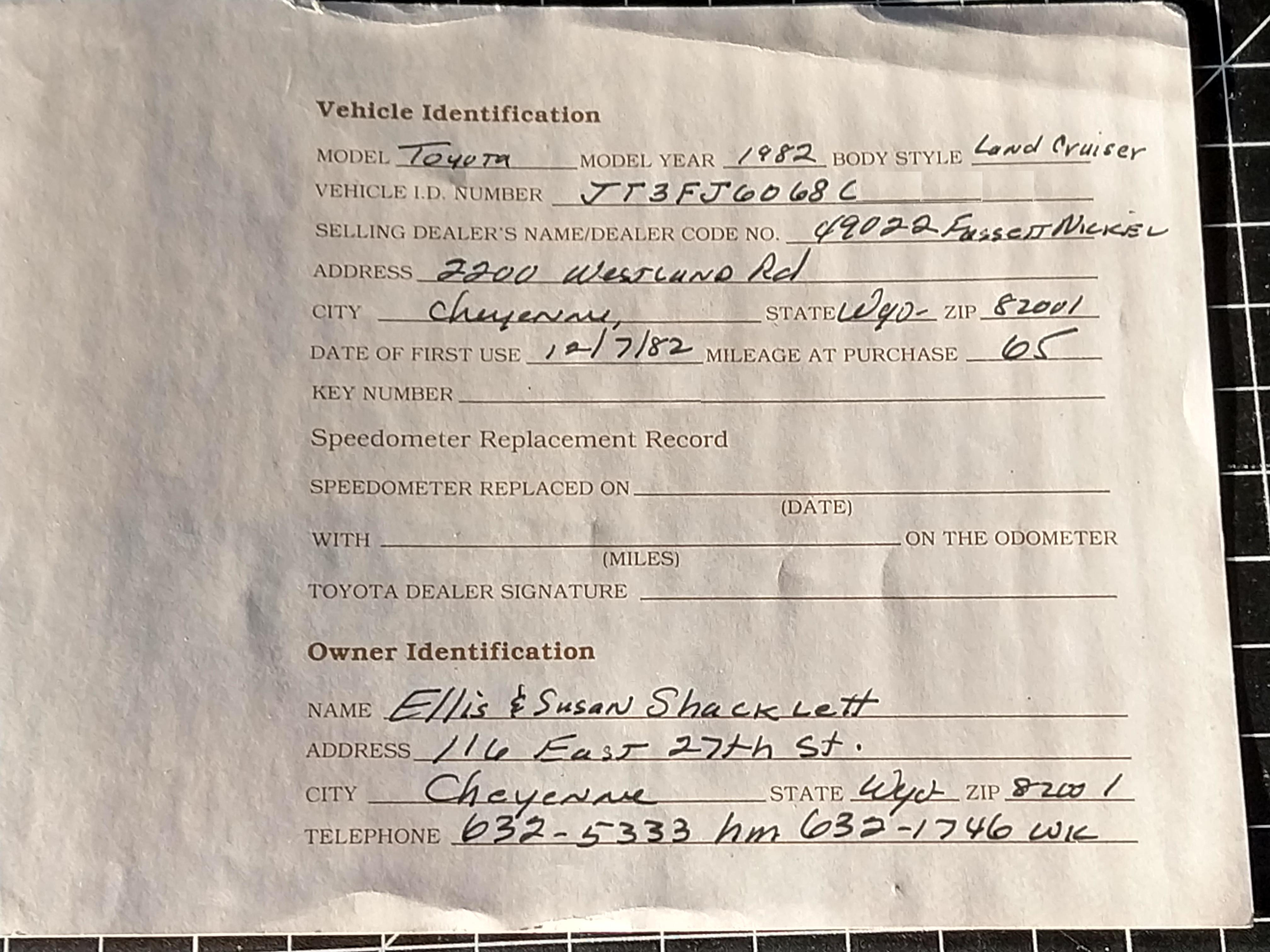

Otherwise I've been discovering lots of new things with Wyoming (Perhaps just Wyo... the old state mail address before it went to WY). Previously I realized that her rear drivers door had been replaced with one from a 62 and some kind folks pointed out that a manual regulator was a plug-n-play replacement. I already have one on it's way. Today I realized the back gate and hatch were replacements too, originally silver and with a wiper... for which I don't have a switch (or washer bag).

So, question #1: Did Toyota use 1 harness for all models, meaning that I can simply connect the correct plugs, install the switch and have a rear wiper and washer (obviously, installing all the other missing parts)?

That leads into Question #2, if Toyota did use one harness, then I probably have superfluous plugs... would these be normally unused?

Drivers side, just behind the headlight... bigger gauge so probably power (looks like red and white):

Passenger side, just behind the battery (looks like green and white w/black stripe in my photo):

Pigtail off the starter? Looks like blue and red:

Just under the brake master cylinder, only a 2-pin but I see white, blue and green:

And then the last wiring question for now, I noticed the brake fluid reservoir has a couple leads for a fluid level idiot light, but I can not find the corresponding vehicle side connection. First thought is that I'm just a blind idiot... second is this FJ didn't have that option and this is a replacement cap.

My search-fu here is weak, I'm simply not finding threads that talk about any of this... and then I get distracted by those threads. Similarly, I'm looking at the manual but its format is different from what I'm used to (no color coded wiring diagram laid out with connectors on the page where you'd find them on the vehicle?), I'm trying, just not finding yet.

Thanks!