Worn hood hinges? (& lathe work)

Do your hood hinges look worn like this?

Many years ago I was fooled into thinking my hinges were badly worn because the pins were quite noticeably off-centre (as in that photo). At that time, replacement hinges were cheap so I just bought another pair. --- Only to discover that the new ones were off-centre too.

The problem is actually caused by poor manufacturing technigue. So if yours look like the one in the photo, they probably aren't worn at all.

Have a look at this. I've cut the pivot out and you can see the plastic bush is quite free of wear. -But note how off-centre it is in the "scroll".

No doubt your now wondering why I mutilated perfectly good hinges. Well, suffering from "obsessive compulsive disorder" I couldn't bear to look at those "worn out looking" hinges anymore. I had to "fix" them and decided to go for "phosphor-bronze bushes" and "grease nipples" at the same time.

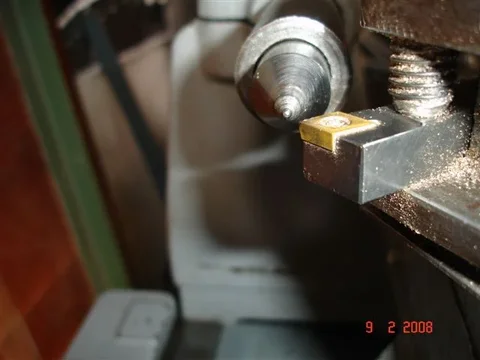

Here is the jig I used to hold the hinge-halves in their correct relationship while I cut out and replaced the pivot arrangement.

I made some measurements too of course. - for instance the pin centre-line was 16mm above the bottom-surface-line. I wanted the new hinges to exhibit exactly the same opening characteristics as the old ones - not that it probably matters much - but that's just me.

Do your hood hinges look worn like this?

Many years ago I was fooled into thinking my hinges were badly worn because the pins were quite noticeably off-centre (as in that photo). At that time, replacement hinges were cheap so I just bought another pair. --- Only to discover that the new ones were off-centre too.

The problem is actually caused by poor manufacturing technigue. So if yours look like the one in the photo, they probably aren't worn at all.

Have a look at this. I've cut the pivot out and you can see the plastic bush is quite free of wear. -But note how off-centre it is in the "scroll".

No doubt your now wondering why I mutilated perfectly good hinges. Well, suffering from "obsessive compulsive disorder" I couldn't bear to look at those "worn out looking" hinges anymore. I had to "fix" them and decided to go for "phosphor-bronze bushes" and "grease nipples" at the same time.

Here is the jig I used to hold the hinge-halves in their correct relationship while I cut out and replaced the pivot arrangement.

I made some measurements too of course. - for instance the pin centre-line was 16mm above the bottom-surface-line. I wanted the new hinges to exhibit exactly the same opening characteristics as the old ones - not that it probably matters much - but that's just me.

Last edited: