About as desmogged as you can make a 2FRemoving it does clean up the engine bay and make it easer to work on.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where to start with 2F engine stalling

- Thread starter Last Flight Out

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?77mustard40

SILVER Star

Late to the party gents. @Last Flight Out do you know the condition of your fuel tank and fuel filter? Sure sounds like you might have some crap that has made its way in the idle circuit in the carb. You can try removing the idle adjustment screw on the base of the carb and blasting it with carb cleaner to try to unseat the blockage. Then reseat to the same depth and see if you can start it.

I run a generic clear filter from NAPA on mine so that I can see what the condition of the filter is at all times.

I run a generic clear filter from NAPA on mine so that I can see what the condition of the filter is at all times.

Well, shoot, i was wrong then.The emission computer will allow the FCS to close under conditions of hi rpm and hi manifold vacuum, like you suddenly let off the gas. It will open back up when the rpm comes down or you open the throttle to lower vacuum. Per the manual, this system cuts off part of the fuel in the slow circuit of the carburetor to prevent overheating and afterburning in the exhaust system. This is called the deceleration fuel cut system, first seen in the 1979 manual. I know earlier trucks had basically a hard wired solenoid on the carb that was not controlled by the emission computer. I'm not a carb expert so I couldn't say what the purpose of that was.

I've only had the hard-wired FCS. The original purpose, as i understand it, was to prevent running on (dieseling) after shut-off.

brian

SILVER Star

About as desmogged as you can make a 2F

View attachment 3088654

View attachment 3088655

View attachment 3088656

They run so much better when all that extra crap isnt bogging them down.

A near naked 2F is a thing of beauty.

I had posted earlier about our idle issues, which now appear to be solved. The original FCS would click, but we replaced it anyway. The replacement would also click, but we still had idle issues. This included when the FCS was powered directly from the battery. We replaced with another FCS from a reputable supplier, problem is gone!Quickly did some tests with digi multi meter:

1) Checked ground/contact with main wiring harness on the chassis side (the green plug/harness that plugs into FCS itself from main): Good

2) Checked switched power on the main wiring harness: 11.5v (did not start car)

3) Checked ground/contact on carb with general point on chassis bolt: Good

4) Checked ground/contact on shorter wire (green plug) on FCS to carb: good

5) With FCS disconnected from main harness, hard wired FCS directly to battery - nice loud click

6) Plugged back together (cleaned with contact solvent) and Switched 12v to listen to FCS - and having trouble hearing it as I have some kind of emission/other relay clicking (its normal), so need to get the wife to get my ear away from the relay that is also switching on. CONFIRMED: strong click with key turn.

7) Checked 15A fuse for Engine - metered fine with contact, but does have original Toyota fuse here ( I was wrong in my post above as it being aftermarket). I do not think this is the issue.

Open to other suggestions.

- Thread starter

- #67

See page #1 - filter was replaced with OEM. Tank was not flushed or inspected.Late to the party gents. @Last Flight Out do you know the condition of your fuel tank and fuel filter? Sure sounds like you might have some crap that has made its way in the idle circuit in the carb. You can try removing the idle adjustment screw on the base of the carb and blasting it with carb cleaner to try to unseat the blockage. Then reseat to the same depth and see if you can start it.

I run a generic clear filter from NAPA on mine so that I can see what the condition of the filter is at all times.

- Thread starter

- #68

Saturday-fun-day....well, not fun and more of the same:

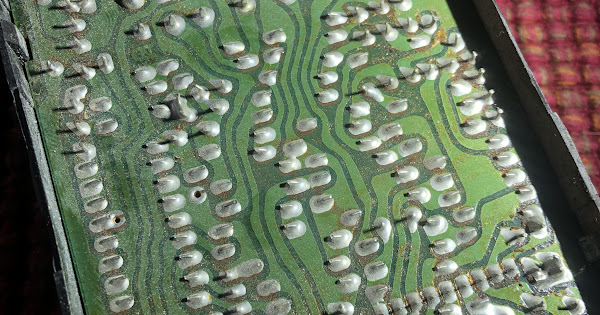

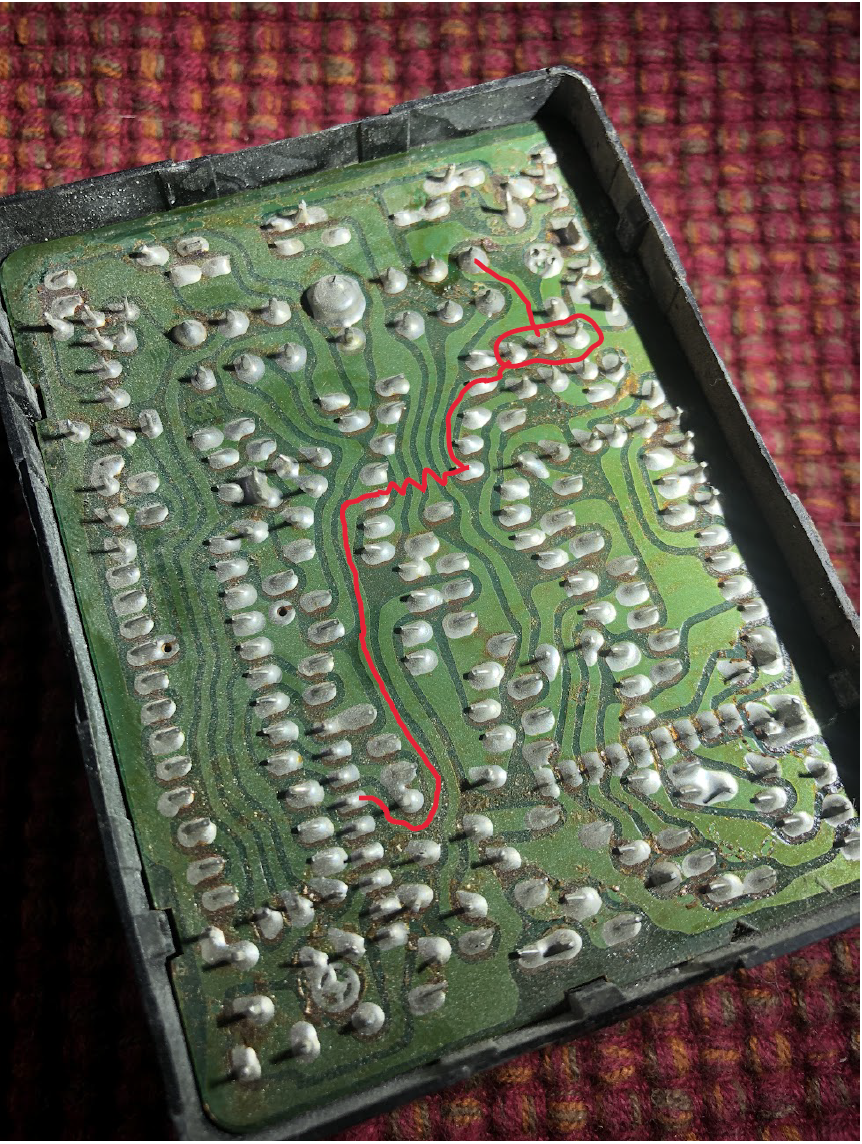

1) Examined by Emissions computer (pics below with detail). Found 3 possible cold joints - but honestly it looked all solid (have experience with circuit bards etc).

2) Cleaned up connector on ECU with connector spray and reinstalled.

3) Hardwired the FCS to the battery. Solid click (yes, I understand you cannot tell with clicks these days).

4) Started/full choke out as normal. Started right up.

5) Let run for about 30 seconds. Fuel in carb window at dead center.

6) Choke into first position - stalls dead, like starving for fuel or air.

Unfortunately I need to get this off to the specialists at @ACC Toyota here in Atlanta.

Emissions ECU pics:

photos.app.goo.gl

photos.app.goo.gl

photos.app.goo.gl

photos.app.goo.gl

photos.app.goo.gl

photos.app.goo.gl

Red arrows for possible cold joints - but they look fine. Reflow to be sure.

photos.app.goo.gl

photos.app.goo.gl

Reflowed potential areas and looking solid. Checked with continuity/meter.

photos.app.goo.gl

photos.app.goo.gl

Video with same results - dead end....

1) Examined by Emissions computer (pics below with detail). Found 3 possible cold joints - but honestly it looked all solid (have experience with circuit bards etc).

2) Cleaned up connector on ECU with connector spray and reinstalled.

3) Hardwired the FCS to the battery. Solid click (yes, I understand you cannot tell with clicks these days).

4) Started/full choke out as normal. Started right up.

5) Let run for about 30 seconds. Fuel in carb window at dead center.

6) Choke into first position - stalls dead, like starving for fuel or air.

Unfortunately I need to get this off to the specialists at @ACC Toyota here in Atlanta.

Emissions ECU pics:

New item by Peter Brusa

photos.app.goo.gl

photos.app.goo.gl

New item by Peter Brusa

photos.app.goo.gl

photos.app.goo.gl

New item by Peter Brusa

photos.app.goo.gl

photos.app.goo.gl

Red arrows for possible cold joints - but they look fine. Reflow to be sure.

New item by Peter Brusa

photos.app.goo.gl

photos.app.goo.gl

Reflowed potential areas and looking solid. Checked with continuity/meter.

New item by Peter Brusa

photos.app.goo.gl

photos.app.goo.gl

Video with same results - dead end....

Did you reflow pin 13 of the connector? That is the VSS input to the computer. It should not impact your idle but it is a bad solder joint. The fuel cut solenoid is on pin 12 above it that looks pretty solid.

- Thread starter

- #70

I’ll reflow 13 when I have the box out again . It’s super easy to work on these archaic computers….just fussy to figure out why.Did you reflow pin 13 of the connector? That is the VSS input to the computer. It should not impact your idle but it is a bad solder joint. The fuel cut solenoid is on pin 12 above it that looks pretty solid.

View attachment 3092095

The transistor that controls the FCS is circled, it is turned on/off depending on the status of pin 6 of the 2582 IC. That all looks pretty solid.

When I found the cold solder joints it took the use of an eye loop magnifier to clearly identify three cold joints (connector).

Each solder joint should have a nice visible flow at the base of the board and around the conductor. Any small cracks must be mitigated by reflowing. Like I mentioned previously, this solved my random stalling issues for good.

Each solder joint should have a nice visible flow at the base of the board and around the conductor. Any small cracks must be mitigated by reflowing. Like I mentioned previously, this solved my random stalling issues for good.

Testing FCS function of 81+ emissions computer.

- Thread starter

- #74

Testing FCS function of 81+ emissions computer.

Interesting….the more I’m digging into this, the more I am thinking it is not the ecu here. I think it is more downstream. But it is based on my hypothesis.

One thing I was going to try was to disconnect the FCs all together and start the truck to see what happens. It may shed some light as to the unit being defective.

- Thread starter

- #75

Yes this is what I have been doing. All viewed and inspected under loop. Again, I can spot cold solder joints easily enough.When I found the cold solder joints it took the use of an eye loop magnifier to clearly identify three cold joints (connector).

Each solder joint should have a nice visible flow at the base of the board and around the conductor. Any small cracks must be mitigated by reflowing. Like I mentioned previously, this solved my random stalling issues for good.

- Thread starter

- #76

So decent update this week:

1) Turns out the FCS is normal and operating as it should - I really went to town on this component with testing and inspection.

2) Looked at fuel delivery and pressure....all in check.

3) Turns out that it was the idle circuit - in particular, needed idle speed and fuel mixture adjustments, but also indicates the carb needs a full rebuild.

4) Will also be using some Stay-Bill as part of my maintenance since the truck can sit for a week (or more at times) when I am super busy.

5) Carb has some debris/varnish from cheap gas, old carb and just sitting at time.

Had him on the highway today and performed great. Had a lot more to go but held it around 60mph for about 15-18 mile trip. This was a big one for me as its the first time I had him on the actual highway.

Starting to reconsider going sniper now....I have an order for one, but as I get to know how stable the carb is, it may be best for my application.

1) Turns out the FCS is normal and operating as it should - I really went to town on this component with testing and inspection.

2) Looked at fuel delivery and pressure....all in check.

3) Turns out that it was the idle circuit - in particular, needed idle speed and fuel mixture adjustments, but also indicates the carb needs a full rebuild.

4) Will also be using some Stay-Bill as part of my maintenance since the truck can sit for a week (or more at times) when I am super busy.

5) Carb has some debris/varnish from cheap gas, old carb and just sitting at time.

Had him on the highway today and performed great. Had a lot more to go but held it around 60mph for about 15-18 mile trip. This was a big one for me as its the first time I had him on the actual highway.

Starting to reconsider going sniper now....I have an order for one, but as I get to know how stable the carb is, it may be best for my application.

77mustard40

SILVER Star

Glad to hear, sure didn’t sound like an electrical issue.

brian

SILVER Star

The carbs are just fine...once tuned and or cleaned/ rebuilt they provide long, maintenance free service lives.

Last edited:

- Thread starter

- #79

That’s what I am stating to consider now…The carbs are just fine...once tuned and or cleaned/ rebuilt they prove long maintenance free service lives.

77mustard40

SILVER Star

X2 … I’m about ten years after I rebuilt my first Aisin and converted my rig back to stock and I’ve had no issues. That said and it’s about time for another rebuild.The carbs are just fine...once tuned and or cleaned/ rebuilt they prove long maintenance free service lives.

Whether it’s carb or EFI, I’d pull my tank and make sure it’s clean and rust / debris free. I was thinking your issue could be an obstruction in the idle circuit, without eliminating the source you may have future issues. Best of luckThat’s what I am stating to consider now…

Similar threads

Users who are viewing this thread

Total: 1 (members: 0, guests: 1)