Arts and Crafts Stage 3 Begins...

And it turns out I'm not as smart as I thought I was. Apparently cardboard

ISN'T an infallible engineering and design tool. Who knew?

Few things I learned today:

1 - Cutting with a cut-off wheel on a circular saw sucks. I was hoping to score the metal to make my bends, and use the circ saw to get a nice straight cut by running along a clamped piece of wood. The thinnest blade for a circ saw has a 1/8" kerf, so the cut sucks and took forever. It's straight though, but a lot of time wasted there. The super thin cut off wheel on a hand grinder works much better for this purpose.

2 - Cardboard isn't perfect. It's floppy, bendy, twists and goes all over. That means that when you make some nice drawings based on your cardboard pieces, they might

ACTUALLY NOT BE PERFECT! Go figure.

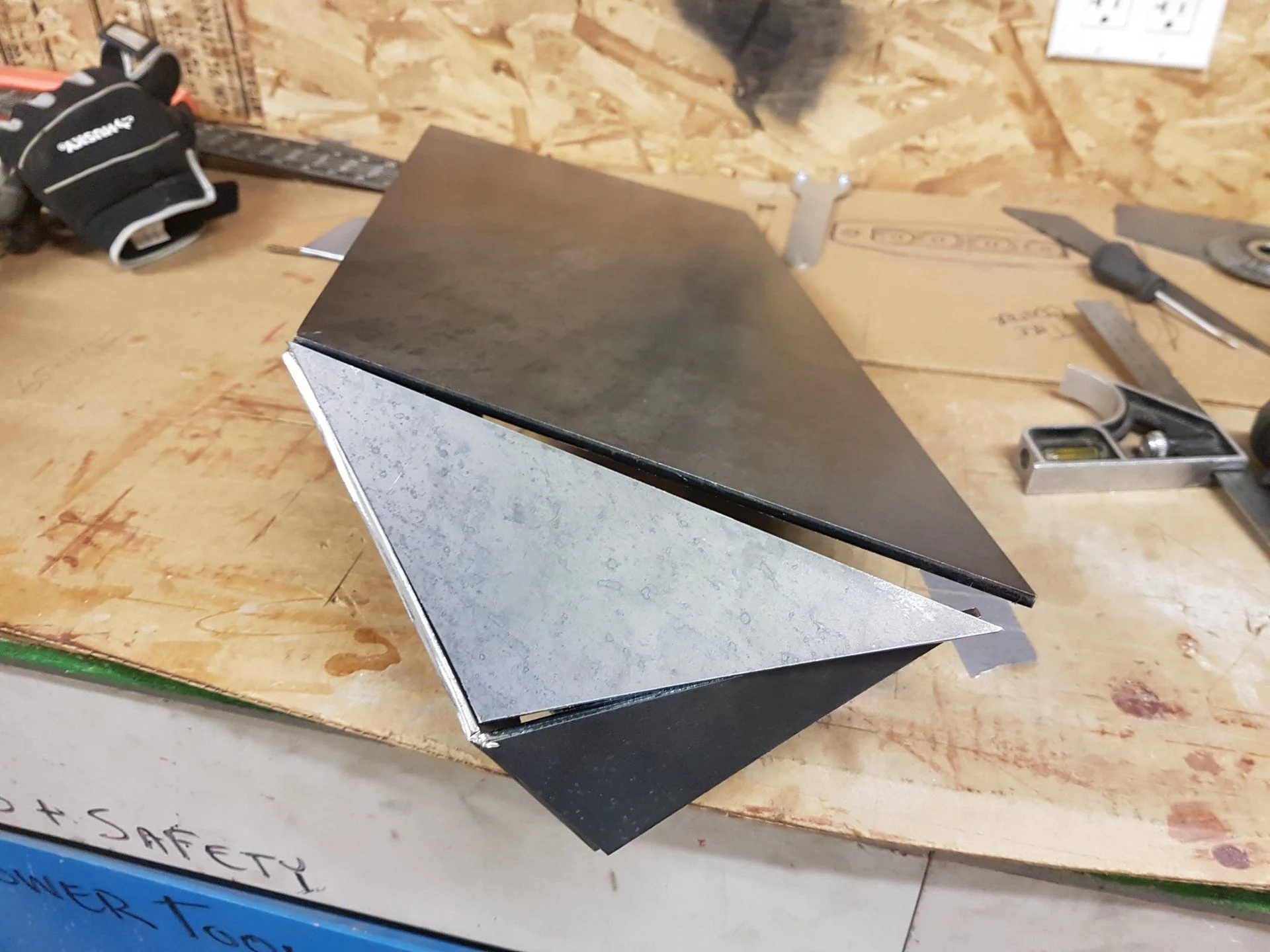

3 - Since it's not perfect, it doesn't bend exactly how you hoped it would (see below), and pieces don't necessarily line up as closely as you hoped. Looks like all the folds I was hoping to do for the wings will be cut off and massaged into place. Not the end of the world, some of my measurements will just end up being about 1/4" smaller than originally made up. Just a lot more wasted time.

4 - Don't bother with bends and folds in metal unless you REALLY know what you're doing. Drawing up stuff in CAD in 2D to get cut is easy, just make every piece separate and tack 'em together. That would have saved me a HECKUVA lot of time.

5 - Laser and Waterjet cutters have a basically non-existent kerf, unlike most other cutting tools. That means when you draw your shapes, you need to take into account the very minor gap you will want in order to make stuff fit nicely. I have to massage pretty much every one of my holes with a file or die grinder and may end up going crazy.

Disclaimer - I'm an electrician by trade, so this was intended to be a learning process. Tube bumpers are easy, it's just like bending electrical conduit. This is a whole different beast. I think I might start a whole thread just on this process so that other people don't make any of the same dumbass mistakes that I did.