Hi,

I've read somewhere on this forum that the Toyota SST used for centering knuckles was a universal fit between LC series and that it was just a matter of using the supplied adapter bushing or not depending on the axle you have. I don't know if this is true or not.

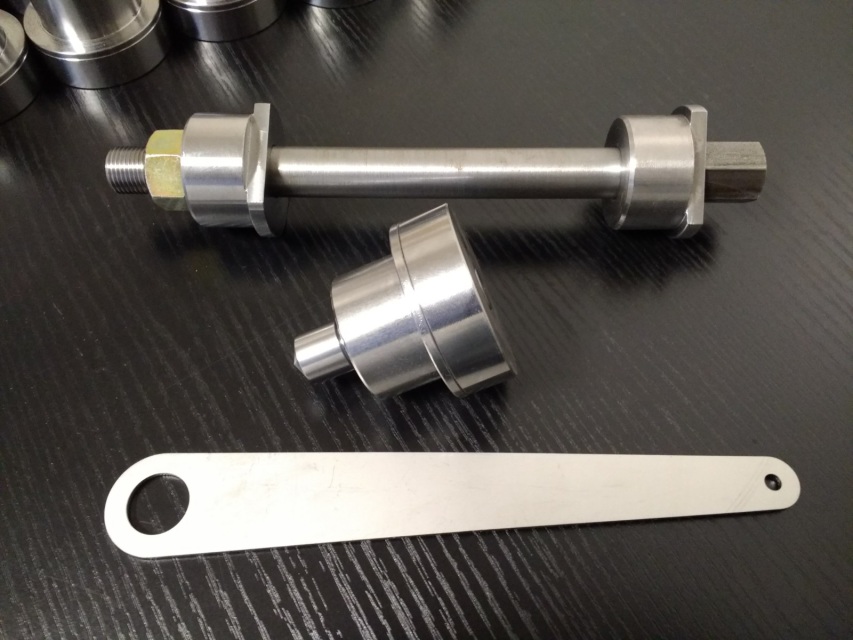

I've just purchased the 09634-60014 model and the shoulder bushing that holds the scribe end is loose inside the axle bore by several millimeters but fits OK inside the spindle (without the bushing).

The FSM I have mentions 09634-60013 which is no longer available so I figured the 09634-60014 must be a replacement. Unfortunately the Chassis and Body FSM I have is for models 3 years after mine (1994 instead of 1991) so I don't know what tool number is appropriate.

What would the appropriate SST model number be for a 1991 PZJ77-MNS ?

If any of you have a similar centering tool I would be curious to know what the OD of the shoulder bushing is. Mine is 39.90mm which was probably intended for a 40.00mm bore. I think mine is closer to 50mm.

Much appreciated!

I've read somewhere on this forum that the Toyota SST used for centering knuckles was a universal fit between LC series and that it was just a matter of using the supplied adapter bushing or not depending on the axle you have. I don't know if this is true or not.

I've just purchased the 09634-60014 model and the shoulder bushing that holds the scribe end is loose inside the axle bore by several millimeters but fits OK inside the spindle (without the bushing).

The FSM I have mentions 09634-60013 which is no longer available so I figured the 09634-60014 must be a replacement. Unfortunately the Chassis and Body FSM I have is for models 3 years after mine (1994 instead of 1991) so I don't know what tool number is appropriate.

What would the appropriate SST model number be for a 1991 PZJ77-MNS ?

If any of you have a similar centering tool I would be curious to know what the OD of the shoulder bushing is. Mine is 39.90mm which was probably intended for a 40.00mm bore. I think mine is closer to 50mm.

Much appreciated!

Last edited: