navydivedoc

GOLD Star

- Thread starter

- #21

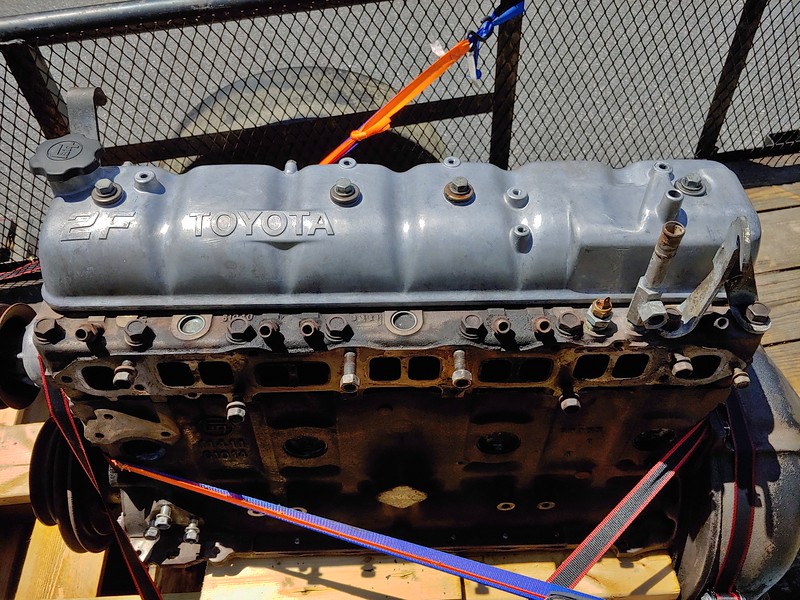

Disappointments today, unfortunately. Pulled all of the necessary parts to get down to the head. That all went fine, and this is an easy motor to disassemble. Plenty of room, most of the skin left on my knuckles. A life in Arizona helped, no rust to fight with.

The good pretty much ended there. My first indication that something was wrong was while pulling the manifold bolts. 14 mm working from the front, but I found the 2 closest to the firewall were a little bigger. 9/16 was a perfect fit. Studs came out instead of the bolts coming off, but no problem, right? Wrong, but I didn't figure that out until a bit later.

Moving on, as I took a better look at the head than I had when I adjusted the valves, I saw this lovely little area

It would appear that I was not the first one to go about pulling this head...and the prior individual was a big fan of JB weld.

After a deep sigh, and the realization that this head was never going to go back on this block, I decided to start pulling head bolts and figured I would find a replacement head without too much drama. Start backing the head bolts out, and none of them had more than maybe 40 ft/lbs of torque. I guess the prior "mechanic" was afraid to stress the JB weld crack repair. Shady shade tree.

Loosened all of the bolts the whole way, and decided to have a beer and take a break. My buddy who was along for the ride and to help lift the monster out mentioned that the second we broke the seal, I had a non-running rig until everything was done, including finding the mystery head. If we bolted it back together, at least I could move it around and get it on a shipping truck if and when my house sells in this crazy market. This man is a genius, and is worth all of the beer he consumes.

We torqued down the head bolts. I put the rocker assembly back on and promptly launched the front spring retaining clip somewhere into my garage, prompting a 30 minute hunt before it was found.

Put the manifolds back on, and low and behold, the stripped out 9/16 SAE thread bolt on the rear wouldn't capture and head and bolt appeared stripped. Of course they were. Fortunately we had made a NAPA run and had a selection of permatex gasket maker. We'd used it liberally on the old gasket anyway, so I filled the entire hole with it. We'll see, but what did I have to lose? Pretty generous use on the water pump and thermostat housing as there were no replacement gaskets to be had today. But, at least the bolts were torqued to spec!

In the end, she fired up without incident. A couple mile drive found her in no worse shape than when we started. It was a rainy day of social distancing anyway, and a good dry run for the eventual real repair. Good times.

Anyone have a 72ish head lying around, no cracks or JB weld?

The good pretty much ended there. My first indication that something was wrong was while pulling the manifold bolts. 14 mm working from the front, but I found the 2 closest to the firewall were a little bigger. 9/16 was a perfect fit. Studs came out instead of the bolts coming off, but no problem, right? Wrong, but I didn't figure that out until a bit later.

Moving on, as I took a better look at the head than I had when I adjusted the valves, I saw this lovely little area

It would appear that I was not the first one to go about pulling this head...and the prior individual was a big fan of JB weld.

After a deep sigh, and the realization that this head was never going to go back on this block, I decided to start pulling head bolts and figured I would find a replacement head without too much drama. Start backing the head bolts out, and none of them had more than maybe 40 ft/lbs of torque. I guess the prior "mechanic" was afraid to stress the JB weld crack repair. Shady shade tree.

Loosened all of the bolts the whole way, and decided to have a beer and take a break. My buddy who was along for the ride and to help lift the monster out mentioned that the second we broke the seal, I had a non-running rig until everything was done, including finding the mystery head. If we bolted it back together, at least I could move it around and get it on a shipping truck if and when my house sells in this crazy market. This man is a genius, and is worth all of the beer he consumes.

We torqued down the head bolts. I put the rocker assembly back on and promptly launched the front spring retaining clip somewhere into my garage, prompting a 30 minute hunt before it was found.

Put the manifolds back on, and low and behold, the stripped out 9/16 SAE thread bolt on the rear wouldn't capture and head and bolt appeared stripped. Of course they were. Fortunately we had made a NAPA run and had a selection of permatex gasket maker. We'd used it liberally on the old gasket anyway, so I filled the entire hole with it. We'll see, but what did I have to lose? Pretty generous use on the water pump and thermostat housing as there were no replacement gaskets to be had today. But, at least the bolts were torqued to spec!

In the end, she fired up without incident. A couple mile drive found her in no worse shape than when we started. It was a rainy day of social distancing anyway, and a good dry run for the eventual real repair. Good times.

Anyone have a 72ish head lying around, no cracks or JB weld?