you must have felt guilty just putting that back down on the ground after...let alone actually driving it anywhere. WOW!I did this same thing to my Torino. wire brush on a grinder for hours. Then, sprayed the whole thing with easy off oven cleaner. Then with a poncho and respirator went at it with a pressure washer with hot water. Finally wiped down with wax/grease remover and painted. Here's some inspiration for you.

View attachment 2966665

View attachment 2966666

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Builds Rediscovering an '87 FJ60 (1 Viewer)

- Thread starter LazarusTaxa

- Start date

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, Skimlinks, and others.

More options

Who Replied?g-man

SILVER Star

not qualified to answer this but have been researching diff rebuild info. This guy seems pretty knowledgeable and gets into marking compound and how to adjust shims at around the 20min mark.Ok I answered my own question about the diff's carrier bearing caps... Inspecting them and how they fit, it's pretty clear which one goes where.

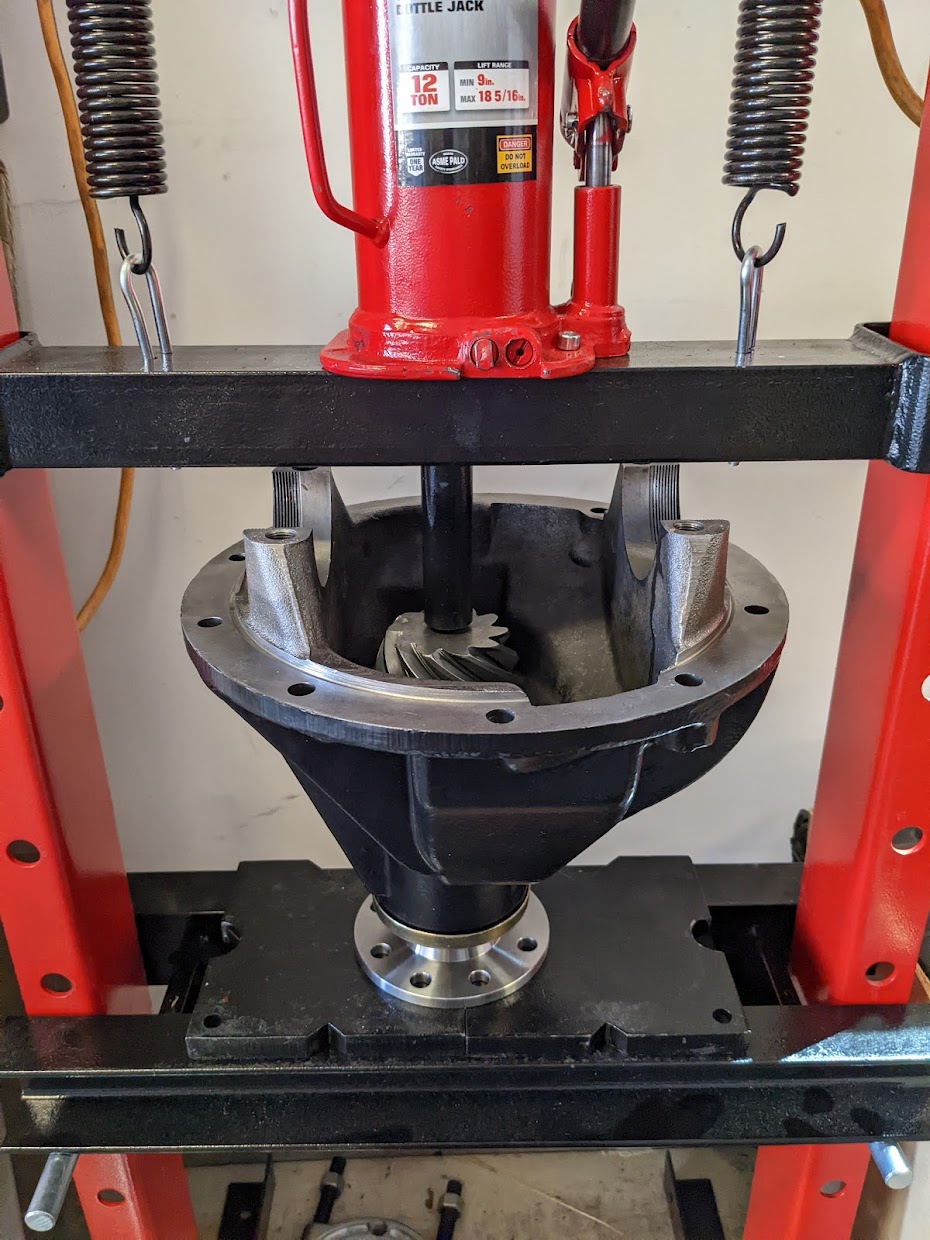

I'm starting w/ my front diff because I've never done this before. I made super ghetto fab diff stand and got to work:

View attachment 2968072

Reading a pattern is definitely something you have to learn.. This is one of those cases where I had someone who knows what they are doing to give advice.. So maybe someone here can help... According to the Nitro Gear booklet, the factory shim left the pinion gear too low in the housing. I messed around and got the following pattern with .001" added.

For those who know, how does this look?

View attachment 2968080

View attachment 2968081

As always, any (knowledgeable) advice is appreciated.

By the way, I dig your simple angle iron/c clamp diff stand.

LazarusTaxa

SILVER Star

- Thread starter

- #123

not qualified to answer this but have been researching diff rebuild info. This guy seems pretty knowledgeable and gets into marking compound and how to adjust shims at around the 20min mark.

By the way, I dig your simple angle iron/c clamp diff stand.

Thanks, that is a great video and super helpful.

The trouble I'm having now is that the sierra gear installation instructions say literally the opposite of what to do to get a good pattern than everyone else.

My pattern is cut off towards the flank (base) of the teeth. According to sierra gear, this means that my pinion gear is too deep. According to everyone else, that means it's not deep enough

I'll keep trying different combos of shims.

LazarusTaxa

SILVER Star

- Thread starter

- #124

A few quick updates from the weekend. I'm finally starting to put parts back together and it feels great..

I got the C-channels back in. I bedded them with grease as others have done in the hopes of filling any voids where moisture can hang out. Unfortunately like half the bolts that cake with the trail tailor kit were too short (any that needed to go through more than the frame and channel. So, like most things I got 90% of the way done and had to pause while I got more bolts. I did take a pic tho:

And, with the rear spring hangers now bolted on for good, I got the springs hung finally. This too had to pause while I sourced a 22mm socket:

And then I spent some time painting the knuckles to cover the exposed metal where the powder stopped:

I still need to clean up the threads for the diff studs, put in the misc. bearing races and seals, and then can get these mounted on the springs.

Other than that, I spend a bit of time dialing in my diff pattern which I think I finally got nailed down.

I got the C-channels back in. I bedded them with grease as others have done in the hopes of filling any voids where moisture can hang out. Unfortunately like half the bolts that cake with the trail tailor kit were too short (any that needed to go through more than the frame and channel. So, like most things I got 90% of the way done and had to pause while I got more bolts. I did take a pic tho:

And, with the rear spring hangers now bolted on for good, I got the springs hung finally. This too had to pause while I sourced a 22mm socket:

And then I spent some time painting the knuckles to cover the exposed metal where the powder stopped:

I still need to clean up the threads for the diff studs, put in the misc. bearing races and seals, and then can get these mounted on the springs.

Other than that, I spend a bit of time dialing in my diff pattern which I think I finally got nailed down.

Dekeman

SILVER Star

Love watching this, keep the pix coming!

LazarusTaxa

SILVER Star

- Thread starter

- #126

I think I got my front diff pretty much nailed down. I realized that I needed to move my pinion down to get a good pattern and that even with only the factory shim, it was still a bit too high. So I took out the factory shim (.053") and added shims under the pinion bearing race, eventually ending up with .048", so bringing the pinion down .005" from factory. I got the resulting pattern, which looks solid:

Then I went to put everything together for the final assembly and had the opportunity to get super pissed.

For anyone who doesn't know, you put the pinion assembly together with a crush sleeve between the two pinion bearings which is slowly crushed as you torque on the pinion flange. This then allows you to fine tune the preload of the bearings.

Everyone, including the mfg instructions, say you can do this with an impact wrench, breaker bar, or in tough cases, get everything started with a press.

I started with an impact gun and that did nothing, so I put it in my 12 ton press to get the sleeve started. That didn't budge. So, I moved on to use a breaker bar as indicated in the instructions.

AND THEN THE PINON NUT STRIPPED... GREAT. Luckily it seems that the threads on the pinion gear itself are usable, which I really hope is true, otherwise I'm out $200+ for another set.

Super frustrating though as I was following the instructions AND industry best practice. Now I need to wait for another nut in the mail and have to figure out how to get this thing on...

Rebuilding diffs is definitely a three banana job.

Then I went to put everything together for the final assembly and had the opportunity to get super pissed.

For anyone who doesn't know, you put the pinion assembly together with a crush sleeve between the two pinion bearings which is slowly crushed as you torque on the pinion flange. This then allows you to fine tune the preload of the bearings.

Everyone, including the mfg instructions, say you can do this with an impact wrench, breaker bar, or in tough cases, get everything started with a press.

I started with an impact gun and that did nothing, so I put it in my 12 ton press to get the sleeve started. That didn't budge. So, I moved on to use a breaker bar as indicated in the instructions.

AND THEN THE PINON NUT STRIPPED... GREAT. Luckily it seems that the threads on the pinion gear itself are usable, which I really hope is true, otherwise I'm out $200+ for another set.

Super frustrating though as I was following the instructions AND industry best practice. Now I need to wait for another nut in the mail and have to figure out how to get this thing on...

Rebuilding diffs is definitely a three banana job.

Are you having trouble getting the sleeve to compress? That's the issue?I think I got my front diff pretty much nailed down. I realized that I needed to move my pinion down to get a good pattern and that even with only the factory shim, it was still a bit too high. So I took out the factory shim (.053") and added shims under the pinion bearing race, eventually ending up with .048", so bringing the pinion down .005" from factory. I got the resulting pattern, which looks solid:

View attachment 2973420

View attachment 2973421

Then I went to put everything together for the final assembly and had the opportunity to get super pissed.

For anyone who doesn't know, you put the pinion assembly together with a crush sleeve between the two pinion bearings which is slowly crushed as you torque on the pinion flange. This then allows you to fine tune the preload of the bearings.

Everyone, including the mfg instructions, say you can do this with an impact wrench, breaker bar, or in tough cases, get everything started with a press.

I started with an impact gun and that did nothing, so I put it in my 12 ton press to get the sleeve started. That didn't budge. So, I moved on to use a breaker bar as indicated in the instructions.

AND THEN THE PINON NUT STRIPPED... GREAT. Luckily it seems that the threads on the pinion gear itself are usable, which I really hope is true, otherwise I'm out $200+ for another set.

Super frustrating though as I was following the instructions AND industry best practice. Now I need to wait for another nut in the mail and have to figure out how to get this thing on...

Rebuilding diffs is definitely a three banana job.

I know how frustrating it is when it goes south while you're going by the book and dotting all your 't's and crossing all your 'i's.

I was rebuilding my steering pump and was torquing the final bolt before I was ready to install it in the truck and it snapped like a tooth pick. I felt no resistance or any indication that anything was wrong other than it seemed to take a long time to get up to torque, and right when I was having that thought it broke. bummer...

LazarusTaxa

SILVER Star

- Thread starter

- #128

Are you having trouble getting the sleeve to compress? That's the issue?

Yep.. I had it clamped in my vice and was going at it with a breaker bar.. I thought I finally got the sleeve to start compressing when I felt it move, but no, that was just the threads disintegrating.

ooof... and the press did nothing at all? Wow. I have no idea were you go from here. Maybe warm the sleeve in the oven a bit before you start at it? Not enough to get it blisteringly hot, but maybe 170?Yep.. I had it clamped in my vice and was going at it with a breaker bar.. I thought I finally got the sleeve to start compressing when I felt it move, but no, that was just the threads disintegrating.

LazarusTaxa

SILVER Star

- Thread starter

- #130

ooof... and the press did nothing at all? Wow. I have no idea were you go from here. Maybe warm the sleeve in the oven a bit before you start at it? Not enough to get it blisteringly hot, but maybe 170?

Yeah, press seemed to do nothing at all, I was legitimately worried about finding out what happens when a bottle jack is overloaded and kinda freaked out it would fail.

Yesterday though, put the crush sleeve by itself in the press and pushed it to 11 and I think I got it to compress ~2mm... My new stake nut should be here today, so I'll try again in my press tomorrow or this weekend. If that doesnt work I guess I'll have to take it to a shop that's got a real 20 ton or something.

I miss my 20 ton press... I should have kept it.

LazarusTaxa

SILVER Star

- Thread starter

- #132

While I wait on the stake nut to get my diffs finished up (hopefully), I moved on to get the rest of the axle parts ready for reassembly... Before I put the wheels on I need to:

Rebuild Birfs

Paint rear axles

Rebuild and paint my calipers

paint my rear drums

I started with rebuilding the birfs which is overall a pretty straightforward and in theory an easy job. There are two kinda tricky parts though that drew out the process for me: getting the axle shafts out initially and getting them back in.. This is because there is a clip on the end which holds the shaft in and needs to be compressed to both remove and insert it back into the joint.

The common method seems to be inserting the axle shaft into a metal pipe or section of PVC, then slamming the birf down on the end. The weight of the axle should then act as a hammer and pull itself free (breaking the clip in the process). For my short axle, this worked fine. For my longer side, it didnt budge.. I ended up clamping the birf end in my vise and using all of my body weight to yank it free.

See here:

Here is everything disassembled and ready for cleaning:

Here is a detail of the clip that holds the axle in the joint.. The upper c-clip prevents the axle from going too far into the joint, the lower loose clip prevents it from coming out:

The trouble reassembling is that it's SUPER hard to keep that clip compressed while you tap the axle into the joint. The best way to do this is using a hose clamp. I dont have any regular clamps that fit, but I do have some of these compression clamps:

It sounds easy from here, but it was super tedious and took probably 20 tries. The issue is that the splines are tight and require some hammering and that the hose clamp doesn't cover very well.. By the time you start trying to tap the axle in, the hose clamp moves and the clip is free to expand. It would probably help to have a typical worm drive clamp.

Anyways, I packed the birf with fresh grease (I used Valvoline Palladium)

I packed the inner splines so that when the axle is pushed in, it forces grease through all the balls which you can kind of see here:

Anddd done.

I also painted the rear axles, but didnt take pics of that.

Rebuild Birfs

Paint rear axles

Rebuild and paint my calipers

paint my rear drums

I started with rebuilding the birfs which is overall a pretty straightforward and in theory an easy job. There are two kinda tricky parts though that drew out the process for me: getting the axle shafts out initially and getting them back in.. This is because there is a clip on the end which holds the shaft in and needs to be compressed to both remove and insert it back into the joint.

The common method seems to be inserting the axle shaft into a metal pipe or section of PVC, then slamming the birf down on the end. The weight of the axle should then act as a hammer and pull itself free (breaking the clip in the process). For my short axle, this worked fine. For my longer side, it didnt budge.. I ended up clamping the birf end in my vise and using all of my body weight to yank it free.

See here:

Here is everything disassembled and ready for cleaning:

Here is a detail of the clip that holds the axle in the joint.. The upper c-clip prevents the axle from going too far into the joint, the lower loose clip prevents it from coming out:

The trouble reassembling is that it's SUPER hard to keep that clip compressed while you tap the axle into the joint. The best way to do this is using a hose clamp. I dont have any regular clamps that fit, but I do have some of these compression clamps:

It sounds easy from here, but it was super tedious and took probably 20 tries. The issue is that the splines are tight and require some hammering and that the hose clamp doesn't cover very well.. By the time you start trying to tap the axle in, the hose clamp moves and the clip is free to expand. It would probably help to have a typical worm drive clamp.

Anyways, I packed the birf with fresh grease (I used Valvoline Palladium)

I packed the inner splines so that when the axle is pushed in, it forces grease through all the balls which you can kind of see here:

Anddd done.

I also painted the rear axles, but didnt take pics of that.

| Part | Number | Quantity |

| Lower birf clip (expanding) | 90520-27091 | 2 |

| Upper birf snap ring | 90520-28036 | 2 |

LazarusTaxa

SILVER Star

- Thread starter

- #133

Got my new stake nut and spent some time this weekend trying tying to get my front diff finished up. I put it back in my press and pushed that thing to 110%. It SUPER struggled, but in the end compressed the crush sleeve enough to work.

I then got to the required 20 in/lbs of bearing preload with a breaker bar. THAT was hard.. I had a friend hold another bar bolted to the flange while I cranked on the breaker bar.. It took everything we had to get that godamn nut tightened. But, it is and it's done. Final pattern:

Coast side could be slightly better, but I honestly think thats as good as its going to get.

I then got to the required 20 in/lbs of bearing preload with a breaker bar. THAT was hard.. I had a friend hold another bar bolted to the flange while I cranked on the breaker bar.. It took everything we had to get that godamn nut tightened. But, it is and it's done. Final pattern:

Coast side could be slightly better, but I honestly think thats as good as its going to get.

LazarusTaxa

SILVER Star

- Thread starter

- #134

I then started on my rear diff.. I didnt show this before, but I was super surprised to see how little toyota cleaned up the castings after machining.. I found burrs like this throughout both diffs:

Pretty crazy they haven't broken off after 185K miles and 35 years.

I started swapping out the bearings on the pinion and carrier and on the last one wondered why it went on pretty easily... Reason because:

Looks like the old carrier bearing spun on the carrier.. Weird, no idea why.

The tolerance with the new bearing is just tight enough so that I can barely pull it off by hand. Definitely too lose to run as it is, but I think using some loctite 660 should fix it. So, waiting on that to get the rear put together.

Pretty crazy they haven't broken off after 185K miles and 35 years.

I started swapping out the bearings on the pinion and carrier and on the last one wondered why it went on pretty easily... Reason because:

Looks like the old carrier bearing spun on the carrier.. Weird, no idea why.

The tolerance with the new bearing is just tight enough so that I can barely pull it off by hand. Definitely too lose to run as it is, but I think using some loctite 660 should fix it. So, waiting on that to get the rear put together.

LazarusTaxa

SILVER Star

- Thread starter

- #135

A bit of a detour from all this focus on the differentials... I have been getting other stuff done, so getting this thread up to speed.

I put new bearings and seals in the rear axle housing and then new seals and knuckle bearing races in the front axle housing as I figured this would be a lot easier off the chassis.

Then I got it all mounted with new hardware, freshly powder coated parts, and new cushions for the rear springs.

I used some wood working clamps to spread the springs while I clamped the axles down:

I put new bearings and seals in the rear axle housing and then new seals and knuckle bearing races in the front axle housing as I figured this would be a lot easier off the chassis.

Then I got it all mounted with new hardware, freshly powder coated parts, and new cushions for the rear springs.

I used some wood working clamps to spread the springs while I clamped the axles down:

LazarusTaxa

SILVER Star

- Thread starter

- #136

Then, added bump stops:

the sway bar back on the front:

and I opted to go with bilstein shocks as I've liked them in the past and hear they are better in this application than OME. I did have to order different bushings for the front shocks... For some reason the lower shock mounts in the front are a larger diameter than the ones in the rear (18mm vs 16mm).. I read this was maybe a change on later trucks? Anyways, yotamasters.com had them for cheap.

Here's everything all mounted:

A few P/Ns from stuff I had to buy new:

the sway bar back on the front:

and I opted to go with bilstein shocks as I've liked them in the past and hear they are better in this application than OME. I did have to order different bushings for the front shocks... For some reason the lower shock mounts in the front are a larger diameter than the ones in the rear (18mm vs 16mm).. I read this was maybe a change on later trucks? Anyways, yotamasters.com had them for cheap.

Here's everything all mounted:

A few P/Ns from stuff I had to buy new:

| Part | Number | Quantity |

| Rear bump stop | 48306-60030 | 2 |

| Front bump stop | 48304-60031 | 2 |

| Rear bump stop bolts | 91611-60822 | 4 |

| Front sway bar bushings | 48815-20030 | 2 |

| Rear shock mount washers (back side) | 90948-03004 | 2 |

| Rear shock mount washers (front side) | 90948-03007 | 2 |

LazarusTaxa

SILVER Star

- Thread starter

- #137

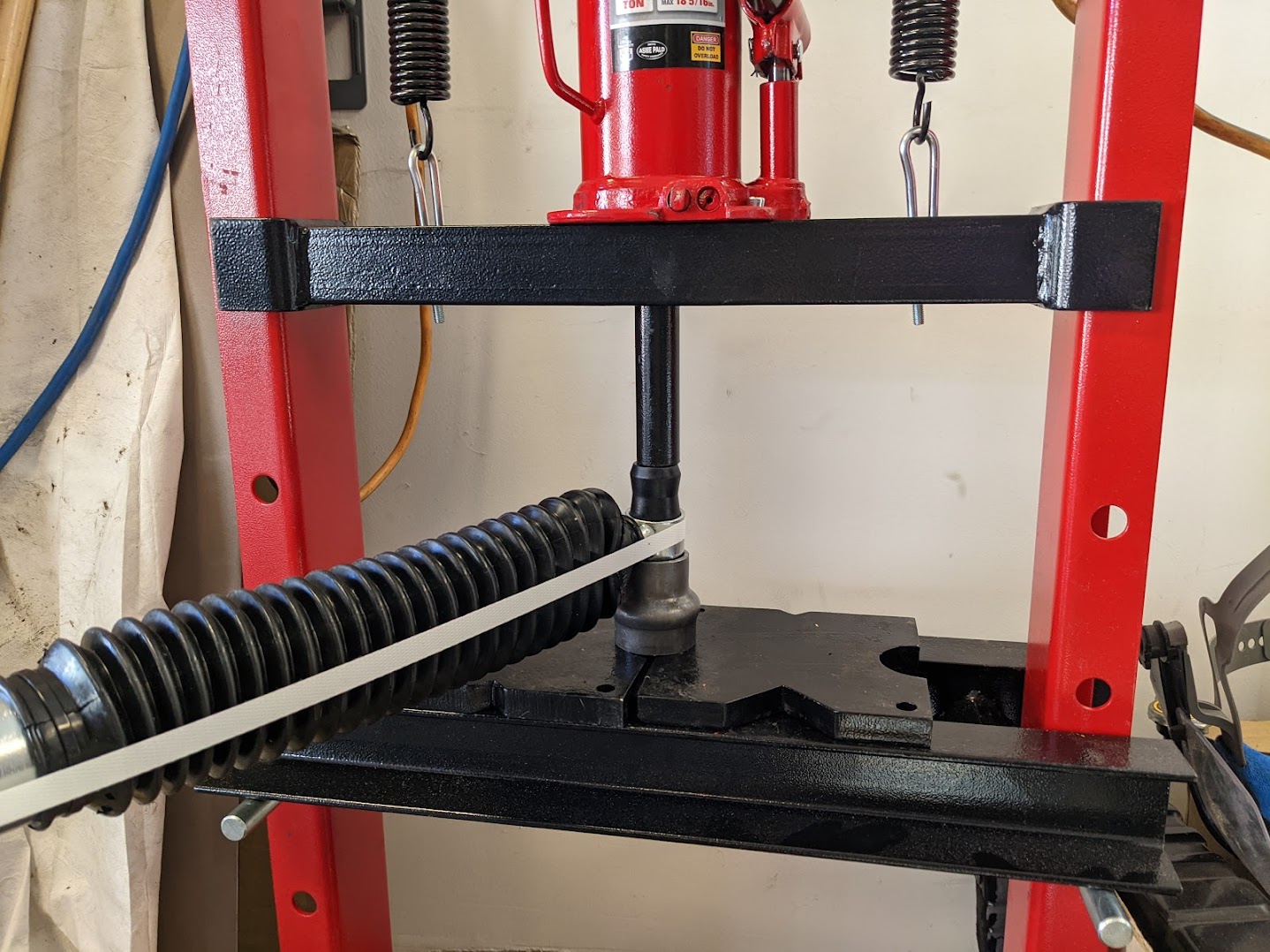

And I also got new studs pressed into my rear axle and front hubs...

I added new "deflector rings" and gaskets on my rear axles as mine were kind of bent.. The rear axles, and a few other parts illustrated why a bigger press is a lot easier.. My small press (almost bench top sized), just doesn't accommodate large parts very well. It would be great to have a full size press and if the Harbor Freight 20ton was in stock, it would probably be a lot better.

No pics of the front studs getting pressed in, but they hold the new brake rotors on the hub.. It was very straight forward.

And then I spent some time getting my locking hubs put back together:

I couldn't match the bronze OE paint with the available colors at my powder coater, but I've always liked red the most so it was an easy compromise.

I added new "deflector rings" and gaskets on my rear axles as mine were kind of bent.. The rear axles, and a few other parts illustrated why a bigger press is a lot easier.. My small press (almost bench top sized), just doesn't accommodate large parts very well. It would be great to have a full size press and if the Harbor Freight 20ton was in stock, it would probably be a lot better.

No pics of the front studs getting pressed in, but they hold the new brake rotors on the hub.. It was very straight forward.

And then I spent some time getting my locking hubs put back together:

I couldn't match the bronze OE paint with the available colors at my powder coater, but I've always liked red the most so it was an easy compromise.

| Part | Number | Quantity |

| Rear axle deflector rings | 42441-30010 | 2 |

| Rear axle deflector gaskets | 42443-55020 | 2 |

| Rear wheel studs | 90942-02052 | 12 |

| Front wheel studs | 90942-02053 | 12 |

| Lug nuts | 90942-01047 | 24 |

| Front brake rotors | 43512-60100 | 2 |

| Locking hub dial o-rings | 43532-60010 | 2 |

@LazarusTaxa I was not able to keep the rubber isolators when I installed my OME leaf springs, and I actively advocate against keeping them. When torquing the U-bolts I found that the torque applied would squish and squish the rubber isolators instead of actually tightening down the leaf pack, and the torque value would not go past about 60ft-lb. I went at one side in particular for about an hour and the rubber was actually getting warm and severely deforming from being under pressure.

I wonder if you’ve torqued those to spec yet, or just put them on loosely.

I wonder if you’ve torqued those to spec yet, or just put them on loosely.

Wow, things are really coming along and looking good!

Which Bilsteins did you go with in the front? I'm looking at switching over to them at some point (from my blown out OMEs) but I'm not sure which valving to get.

As I understand it, the options are:

- 33-230368 with 360/80 valving

- 33-230351 with 255/70 valving

I am leaning towards the 360/80 valving since I have a bumper/winch, but I'm still waffling.

Which Bilsteins did you go with in the front? I'm looking at switching over to them at some point (from my blown out OMEs) but I'm not sure which valving to get.

As I understand it, the options are:

- 33-230368 with 360/80 valving

- 33-230351 with 255/70 valving

I am leaning towards the 360/80 valving since I have a bumper/winch, but I'm still waffling.

LazarusTaxa

SILVER Star

- Thread starter

- #140

@LazarusTaxa I was not able to keep the rubber isolators when I installed my OME leaf springs, and I actively advocate against keeping them. When torquing the U-bolts I found that the torque applied would squish and squish the rubber isolators instead of actually tightening down the leaf pack, and the torque value would not go past about 60ft-lb. I went at one side in particular for about an hour and the rubber was actually getting warm and severely deforming from being under pressure.

I wonder if you’ve torqued those to spec yet, or just put them on loosely.

They're torqued to 90 ft/lbs... They definitely squish out a ton, but they did get to the proper torque.

Wow, things are really coming along and looking good!

Which Bilsteins did you go with in the front? I'm looking at switching over to them at some point (from my blown out OMEs) but I'm not sure which valving to get.

As I understand it, the options are:

- 33-230368 with 360/80 valving

- 33-230351 with 255/70 valving

I am leaning towards the 360/80 valving since I have a bumper/winch, but I'm still waffling.

I totally forgot to add those part numbers.. An honestly, no idea what valving they are, I just went with what @HemiAlex recommended in a thread somewhere..

| Part | Number | Quantity | Note |

| Front shocks | 33-230368 | 2 | Bilstein |

| Rear shocks | 33-185606 | 2 | Bilstein |

If I had my truck put together when I ordered these and could measure full droop and compression, I'd have preferred to order FOX 2.0s. I've got them on another vehicle and they are my favorite of the "mid tier" shocks that don't get into the adjustable on the trail, remote reservoir price range.

Similar threads

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)