Hi Guys -

#307 - 700R4 - 383 Stroker

I've been loosely (so much so that I didn't know there is/was an HD version) following this thread for years and figured I would do some research prior to installing my Orion. I purchased case #307 from AA in June/July 2006.

Assuming that the popping out of gear happens on the non-HD version as well, it looks like there have been some upgrades to help keep them in gear. What I would like to know is if my case was shipped with the upgrades or not.

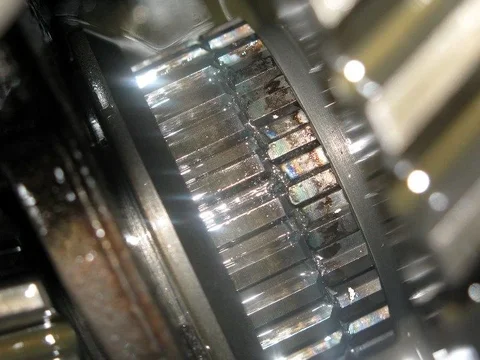

I assembled the case using what came in the kit, in addition to the bits and pieces needed from the donor case. I have the 4:1 so the shift fork is new and I believe the shift rail is new too. What I don't know is if I have the "upgraded" shift collar, detent ball/spring and back-cut gear.

One would think this is a simple question for AA to answer. I called and talked with Matthew yesterday and he started talking about checking the bearing run out and the gap between the shoulder and low range gear and so on. We went round and round a bit but at the end of the day, he didn't answer my question.

I assembled the case nearly 5 years ago but it has not yet been run. Before I put it in the rig and button everything up, I want to find out if I should change/upgrade it in any way. Now is the time to do it.

With that said (sorry for the long post), does anyone know if cases 307 and higher had the "upgraded" parts (shift rail, collar, back-cut gear) or not?

Thanks!