Update! - The manifold is as ready as it's going to get. I started out with gaps as large as .026 at the top edge of my exhaust manifold! That could have been a result of separating the manifolds or when I put them back together with two fresh gaskets and the insulator plate, but that's as close as I could get them by mounting them with no gasket loose, then tightening to spec.

I do like the table / aquarium glass and sandpaper glued down. Plus, i was able to put an office desk to work, seeing as how we're all WFH these days. It's one that adjusts up and down, so I was able to get it a proper height for pulling and pushing that manifold back and forth.

Anyway, the process was - pull the manifold back and forth for the length of a song, then rest, measure, drink some beer for one song, then back to it. Started wit 80 grit, finished with 220. Was able to get the bottom edges of the manifolds down to less than .008 (thinnest feeler I have), middle of exhaust ports to .010 (within spec) and to .015 at the top edge of 4 and 5 and .013 on 2 and 3. Not perfect, but I was worried about taking any more off. Considering the Remflex gasket says it's good out to .0625, I think we'll be good. I really wanted every port to be shiny and smooth, but I'll have to settle for this.

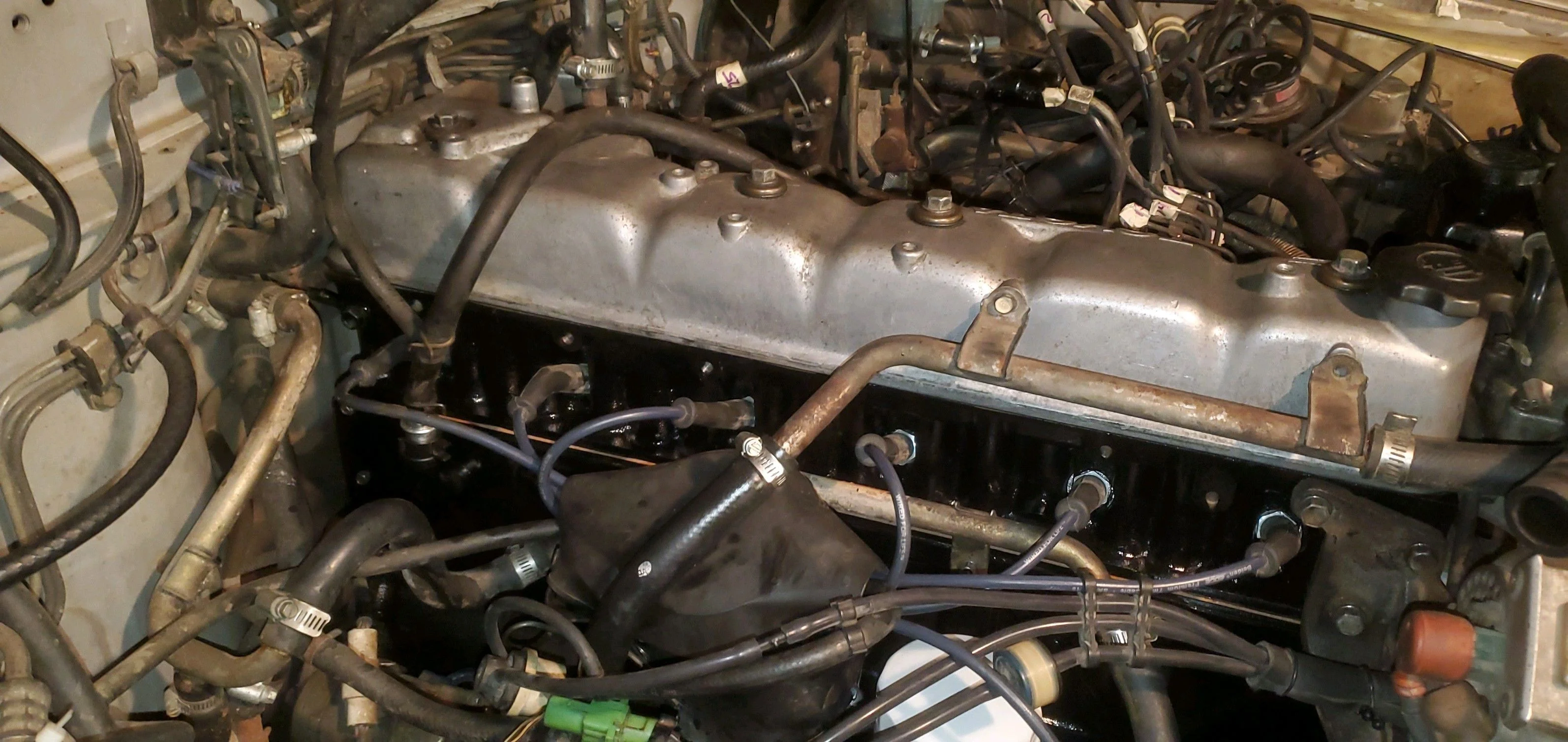

Notice in the pics how the bottom of the exhaust ports are smooth and shiny. That's where the leak was prevalent and I think that's been addressed.

I'd say overall, it was probably 30-40 minutes of actual sanding.

Used RTV Orange to keep the horns in place.

Table: